Method for reinforcing shear wall structure deformation joint template using fixing plate

A technology of structural deformation and template fixing, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, etc. It can solve problems such as waste of materials, prolonging the construction period, and running molds, and achieves easy operation, Guarantee the effect of project progress and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

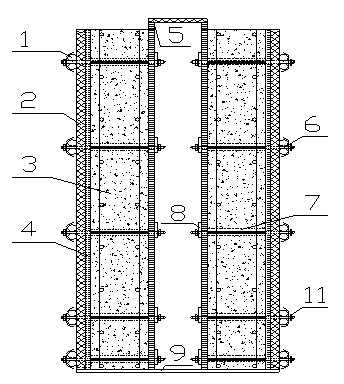

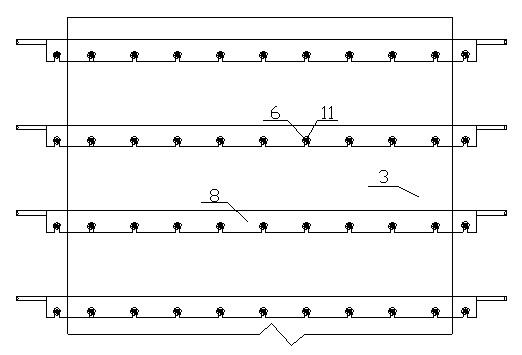

[0018] A method for strengthening the formwork fixing plate of the deformation joint of the shear wall structure according to the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The first step is to make the fixed plate.

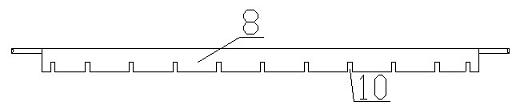

[0020] First determine the length, width, thickness and other technical parameters of the fixed plate (8) according to the length and thickness of the shear wall structure and the width of the deformation joint, and then process and manufacture the fixed plate so that the fixed plate meets the requirements of on-site construction quality. Strength needs. The fixed plate (8) is as figure 1 As shown, it is generally a rectangular member made of 3-4mm thick steel plate, which is used as the back of the formwork inside the deformation joint, and a handle is welded at both ends of one long side of the fixed plate (8), and the other long side is connected to the tension screw ( 6) A reserved notch is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com