Stone cladding stone slab fixing structure with high anti-seismic function

A technology for dry-hanging and fixing the structure of stone, applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of increasing the load-bearing of buildings, complicated construction process, and large loss of ceramic plates, so as to reduce the bearing capacity and keep clean. Beautiful appearance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

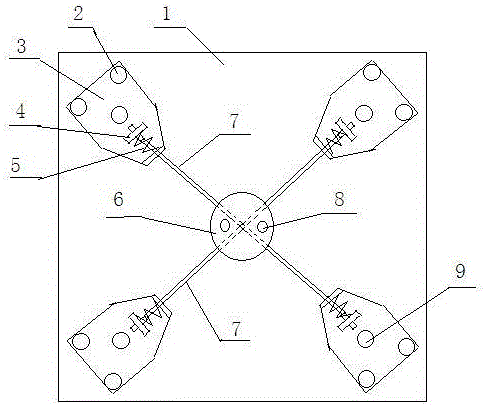

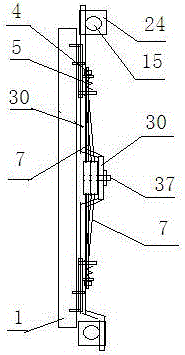

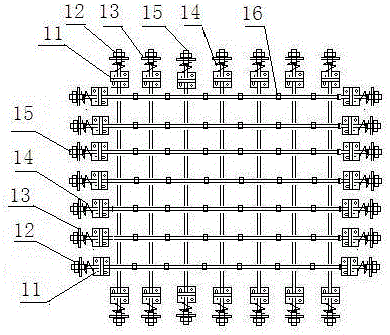

[0031]Illustration: a stone dry-hanging stone slab fixing structure with high anti-seismic function, including wall fixing net, stone slab fixing structure, wall fixing net: including vertical hanging steel wire pull rope 10, horizontal steel wire pull rope 15, composed of vertical steel wire The stay ropes 10 and horizontal steel wire stay ropes 15 are arranged crosswise, wherein the spacing between the vertical hanging and pulling steel wire stay ropes 10 is determined by the size of the stone layout, and the arrangement of the vertical hanging and pulling steel wire stay ropes 10 matches the arrangement of the vertical seams of the stone; The layout of the steel wire stay rope 15 matches the layout of the transverse joints of the stone, and the two ends of the steel wire stay rope are fixed by the wall corner bracket 11 and the wall surface spring 14; the wall corner bracket includes the body B, and the body B structure includes a vertical panel 18 and a horizontal panel 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com