Intelligent equipment for component hoisting and manufacturing method of equipment

A technology for equipment and components, applied in the field of intelligent equipment for component hoisting, can solve problems such as harsh operating environment, affecting production activities, and difficulty, achieving the effects of high safety, convenient hoisting and construction, and guaranteeing the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

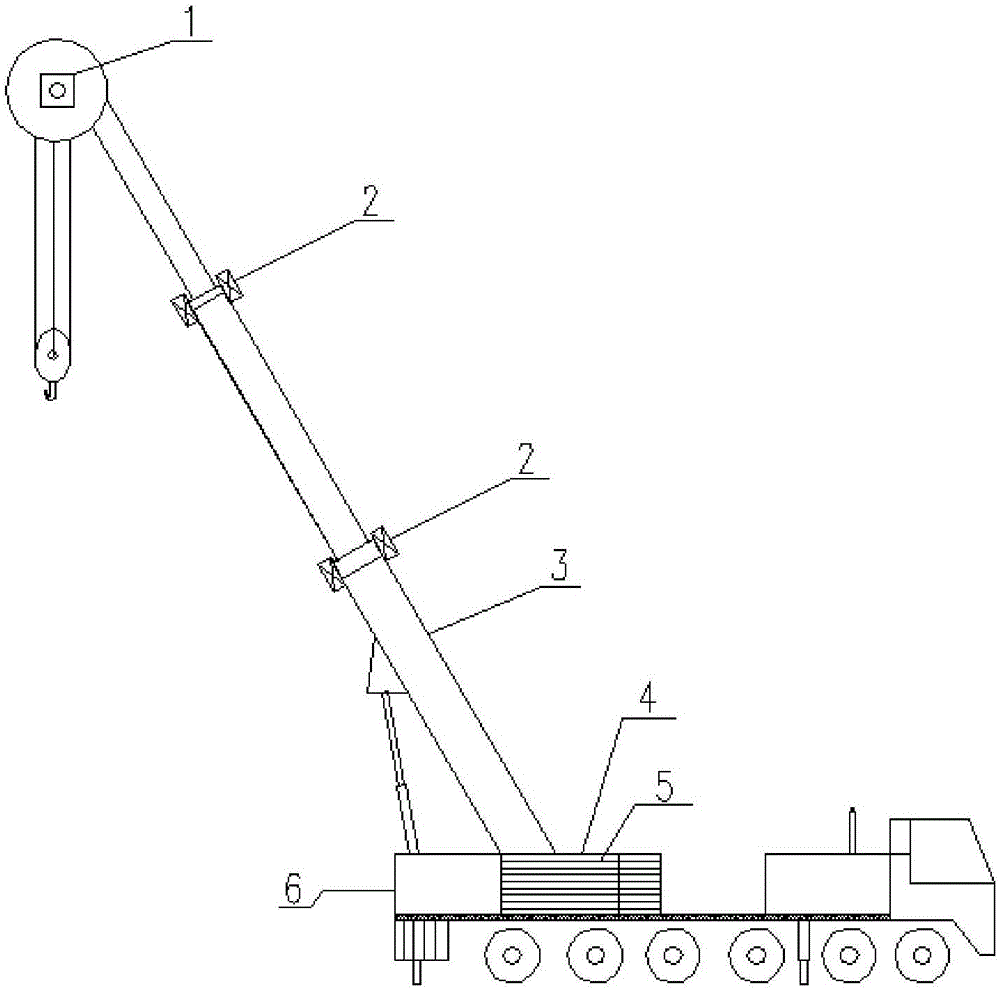

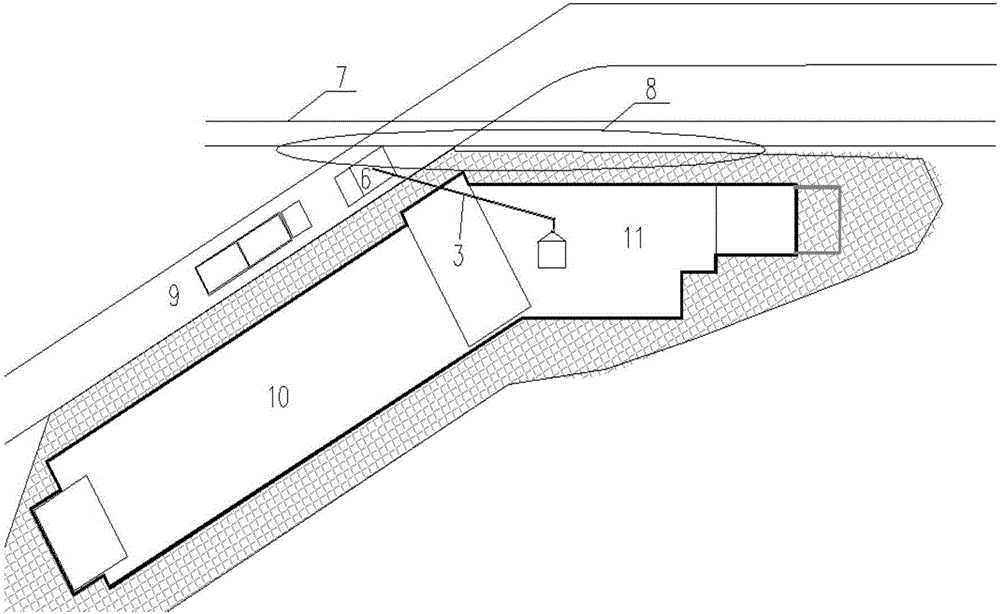

[0010] Embodiment of the present invention: a manufacturing method of component hoisting intelligent equipment, the method is equipped with a movable radar device and a camera on the crane boom, and equipped with an information receiver in the office and the crane control room; when the boom is close to the high-voltage line 7 , that is, when it reaches the radar sensing area 8, the radar will transmit the information to the crane driver's operation office and office and express it in the form of an alarm sound, so that the crane driver and office management personnel can make timely adjustments to avoid accidents; when the crane When hoisting components and other materials to the second floor or above, the driver cannot see the hook and the materials being hoisted. At this time, the command personnel close to the above convey information to the underground driver in the form of voice, which is also relatively easy to cause safety accidents At this point, a high-definition came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com