Base compacting device of dry-type transformer coil

A dry-type transformer and compression device technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc. Disadvantages and other problems, to achieve the effect of extending the creeping distance, saving the cost of the mold, and reducing the differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

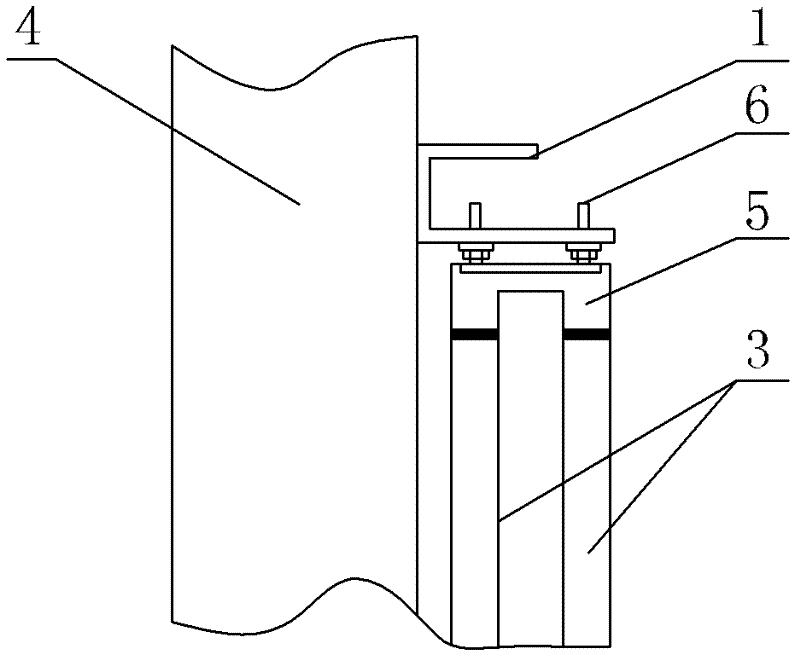

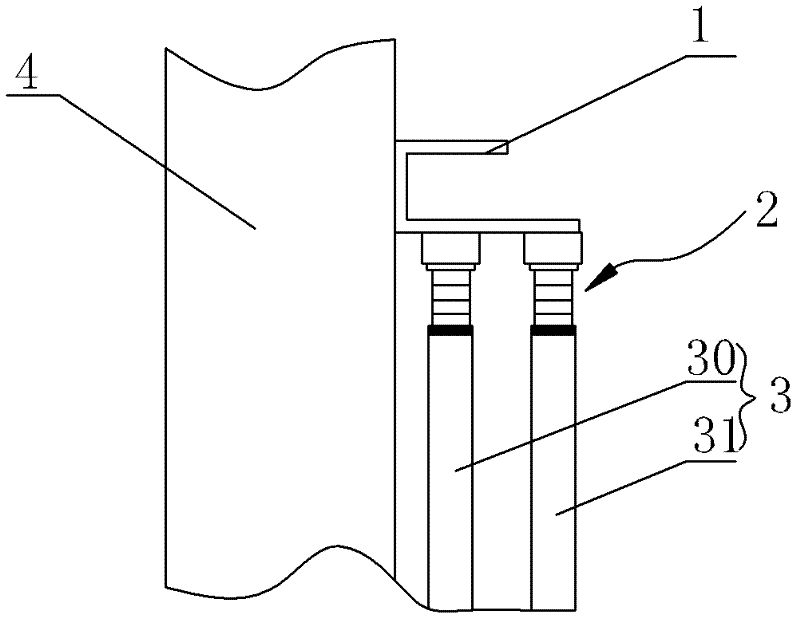

[0024] Such as figure 2 The shown base pressing device for a dry-type transformer coil includes a clamp 1 connected to the iron core 4 of the transformer, a base assembly 2 connected to the clamp 1, and the transformer coil 3 is pressed against the base on component 2.

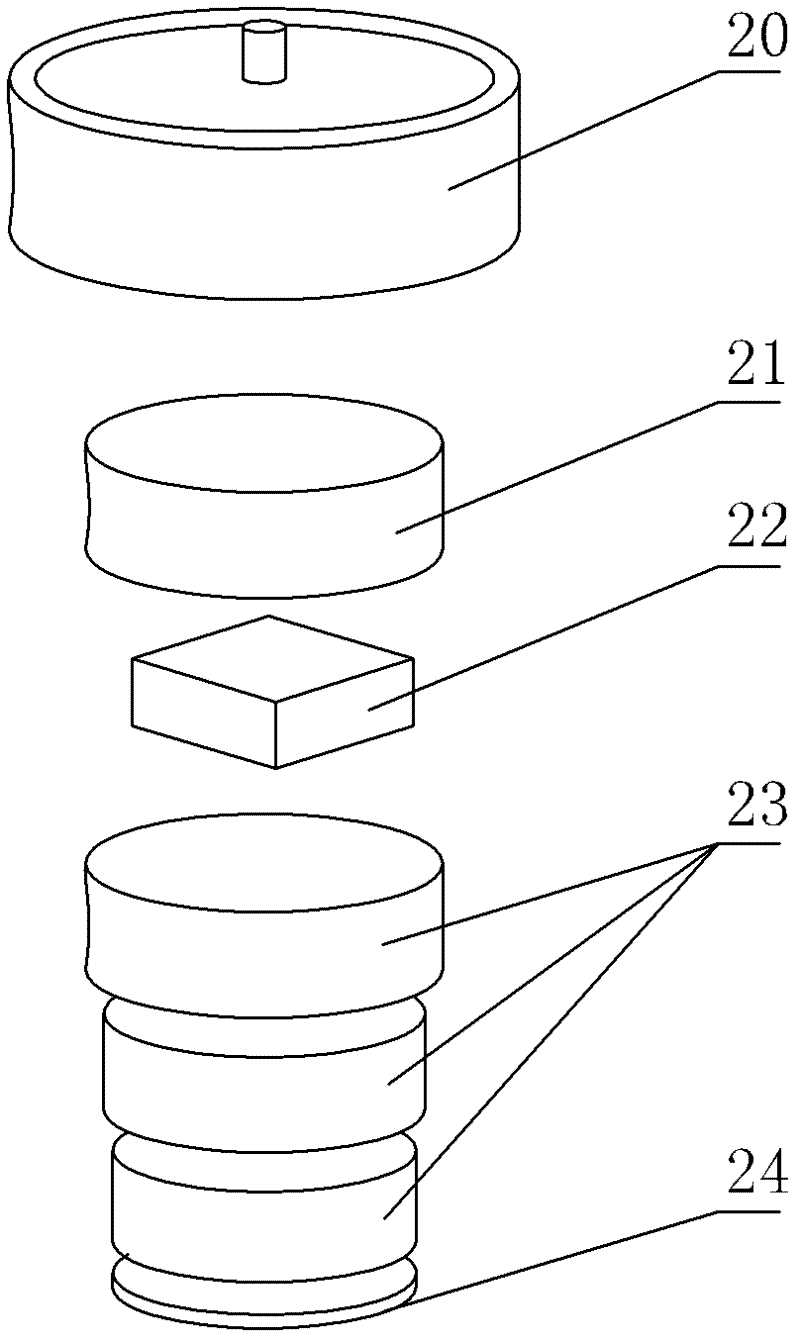

[0025] Such as image 3 As shown, specifically: the base assembly 2 includes a base cap 20, a base 21, at least one base adjustment block 22, at least one base post 23, and an insulating cushion 24 disposed at the bottom of the base post 23 . The base cap 20 is connected to the clamp 1, and can be connected to the clamp 1 through its own locking device; the base 21 is sleeved inside the base cap 20, and the two are connected by threads. The base 21 has a Cavity; the position base adjustment block 22 can choose elastic parts, such as rubber or silicon rubber, and its quantity and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com