Middle phase fixing piece of horizontal conductor

A technology of horizontal wires and fixing parts, which is applied in the direction of electrical components, cable suspension devices, cable installation, etc., which can solve the problems of high labor intensity, easy to break wires, broken strands or broken wires, etc., to reduce the risk of work , Prevent disconnection events and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

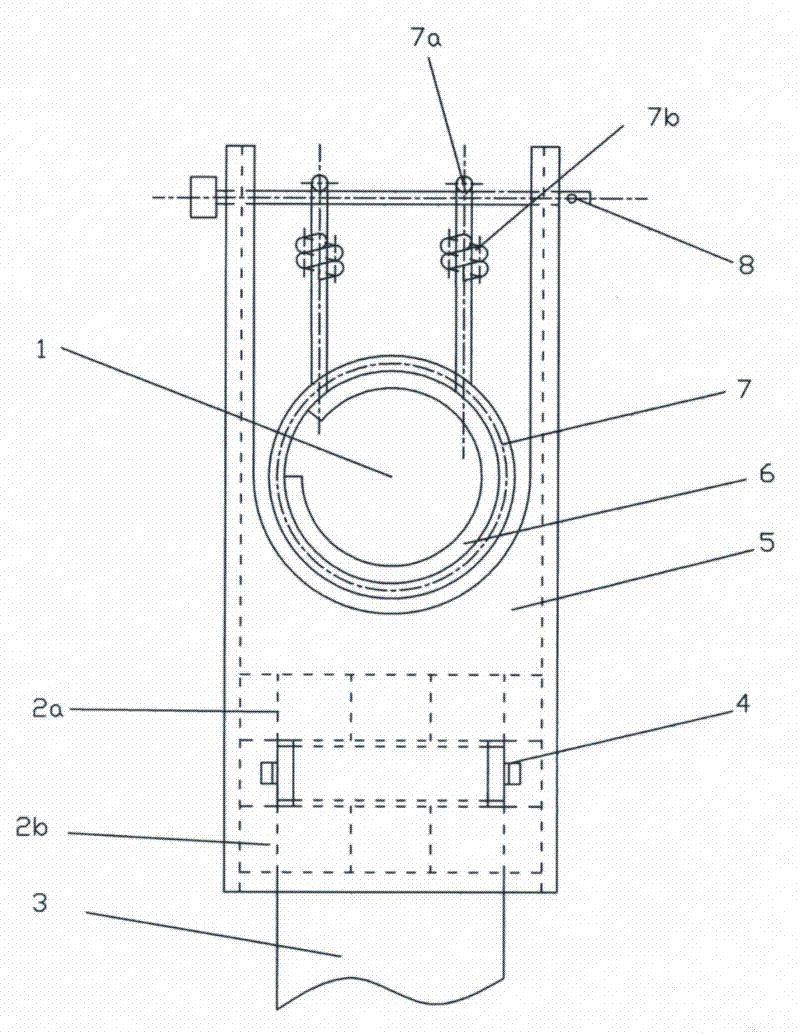

[0016] The invention is composed of (porcelain rod) circlip, support seat, (support seat) fixed rubber sleeve, pin, wire spring, (wire) open rubber sleeve and the like. Pins consist of pins, flat washers and cotter pins.

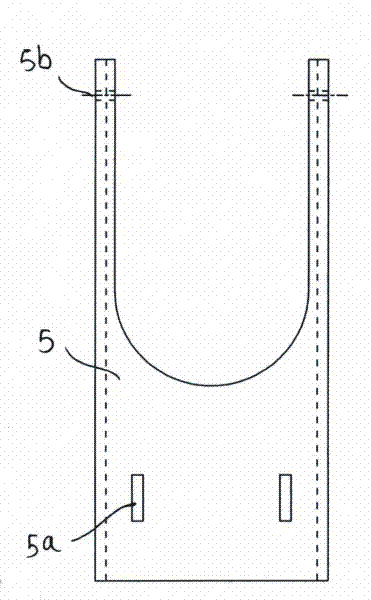

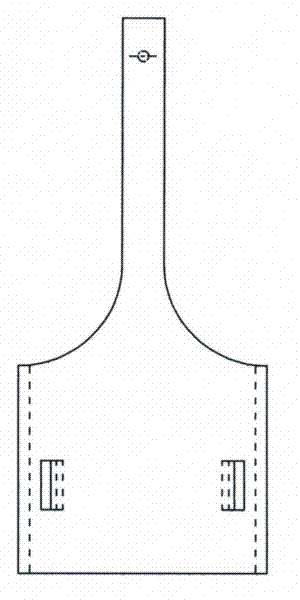

[0017] figure 1 As shown, the structure of the phase-fixing part of the horizontal wire, the support seat 5 is: the two sides of the cylinder extend upwards respectively to form left and right hanging plates, and the pins 8 are inserted into the two hanging holes 5b of the left and right hanging plates ; The structure of the wire spring 7 is: a horizontal helical spring (such as figure 1 There are 8-9 circles in the middle), and the two ends respectively extend upwards in the vertical direction, and spirally coiled into a vertical spring 7b ( figure 1 There are 3 circles in the middle), and finally wind up to make a hanging ring 7a; the wire spring 7 is suspended on the pin 8 through the two hanging rings on it; the opening rubber sleeve 6 used to fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com