Fastener stringer, slide fastener, and objects with attached fasteners

A technology of zipper teeth and zipper tape, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve problems such as electromagnetic wave gap leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

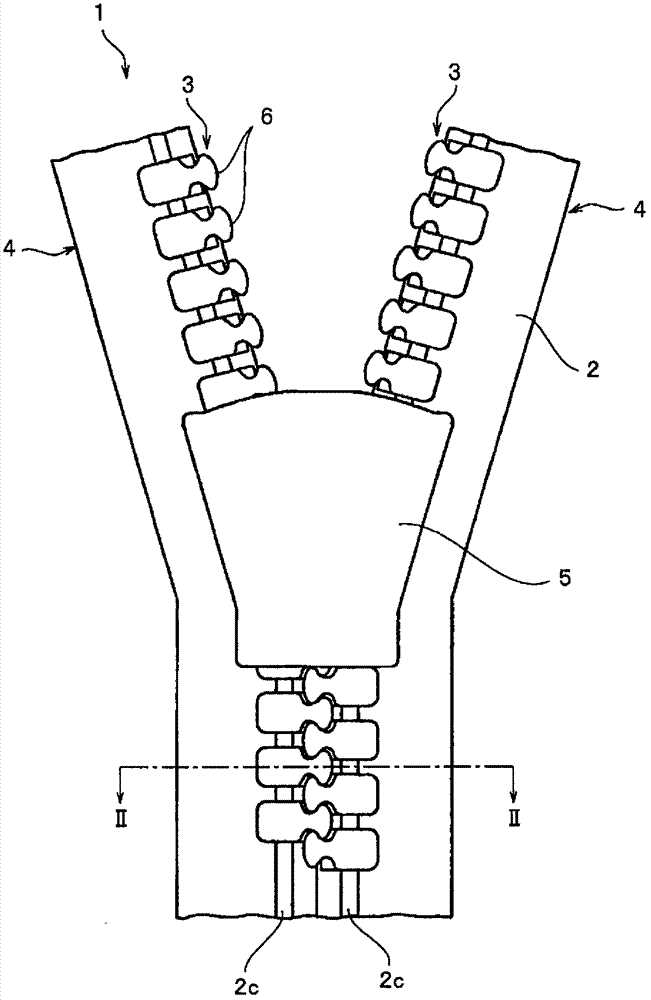

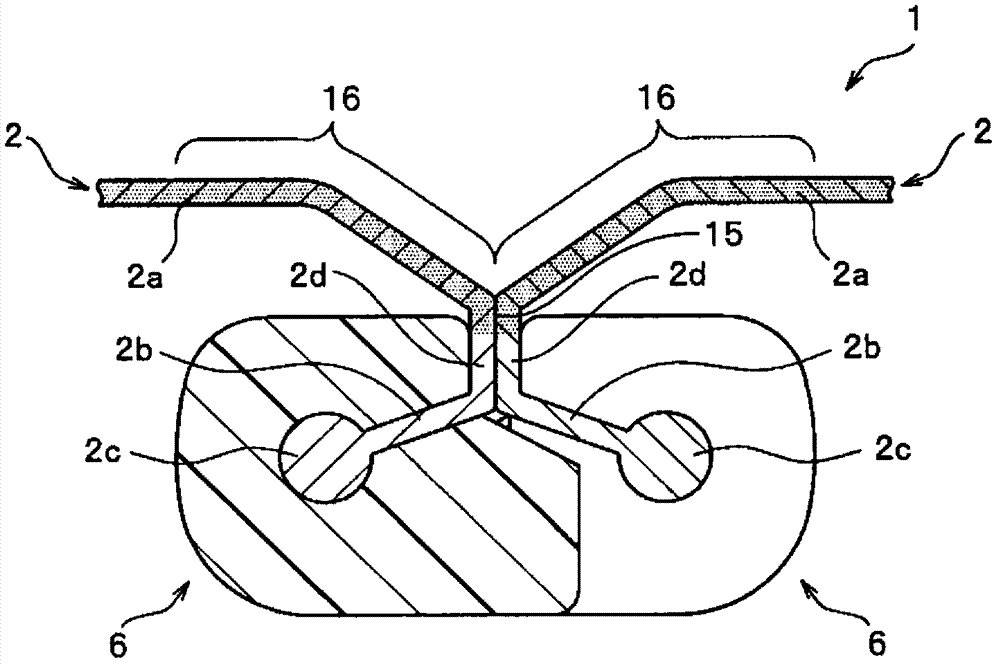

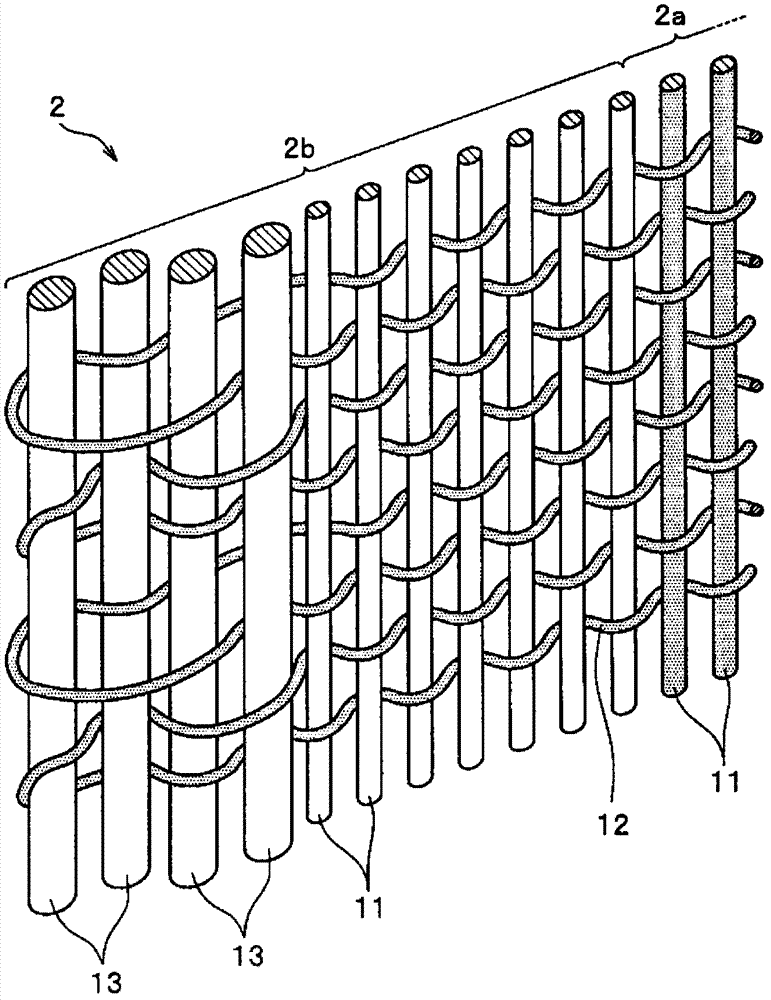

[0070] figure 1 It is a front view showing the slide fastener of Example 1 of the present invention, figure 2 yes figure 1 The II-II line sectional view shown. in addition, image 3 is a partial perspective view schematically showing the weaving structure of the fastener tape in the slide fastener, Figure 4 It is a perspective view which shows the fastener element used for this slide fastener.

[0071] In addition, in this embodiment 1 and the embodiment 2 to embodiment 5 described later, the tape length direction of the fastener tape is the front-rear direction, the tape width direction is the left-right direction, and the direction orthogonal to the front-rear direction and the left-right direction ( Or with the front and back direction) for the up and down direction to explain each zipper.

[0072] The slide fastener 1 of the present embodiment 1 is constituted as a so-called hidden slide fastener, and has: a pair of left and right fastener stringers 4 formed by at...

Embodiment 2

[0097] Figure 7 It is a sectional view which shows the slide fastener which concerns on Example 2 of this invention. In addition, in the second embodiment and the third to fifth embodiments described later, members having the same configurations as those described in the above-mentioned embodiments are denoted by the same reference numerals, and thus descriptions thereof are omitted.

[0098] The slide fastener 41 of the present embodiment 2 is constituted as a hidden slide fastener, and has: a pair of left and right fastener stringers 44 formed by attaching an element row 43 to a fastener tape 42; The unillustrated pull head on 43. Moreover, each fastener stringer 44 on either side has the fastener tape 42 and the coil-shaped continuous fastener element 46 which forms the element row 43 attached to this fastener tape 42, respectively.

[0099] The left and right fastener tapes 42 in this Example 2 each have a tape main body part 42a and an element attaching part 42b arrang...

Embodiment 3

[0108] Figure 8 It is a front view showing the slide fastener of Example 3 of the present invention, Figure 9 yes Figure 8 IX-IX line sectional view shown. in addition, Figure 10 It is a perspective view which shows the regulation member used for this slide fastener.

[0109] In the slide fastener 51 of the present embodiment 3, the inner surface of the fastener element mounting portion 42b of the fastener tape 42 bent into a U shape (the tape on the opposite side to the tape surface of the fastener element mounting portion 42b where the continuous fastener elements 46 are sewn) surface), there is a restriction member 52 that is sewn together with the continuous fastener element 46 by the double-thread loop stitching of the sewing thread 48, and the configuration other than the restriction member 52 is substantially the same as that of the aforementioned embodiment 2. .

[0110] Such as Figure 10 As shown, the restricting member 52 of the third embodiment has: a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com