Motor vehicle headlamp detection system

A detection system and headlight technology, which is applied in the direction of testing the alignment of automobile headlights, testing of machine/structural components, measuring devices, etc., can solve problems such as fraud, laborious and laborious, and reduce the degree of automation, and achieve simple inspection , high inspection efficiency, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below:

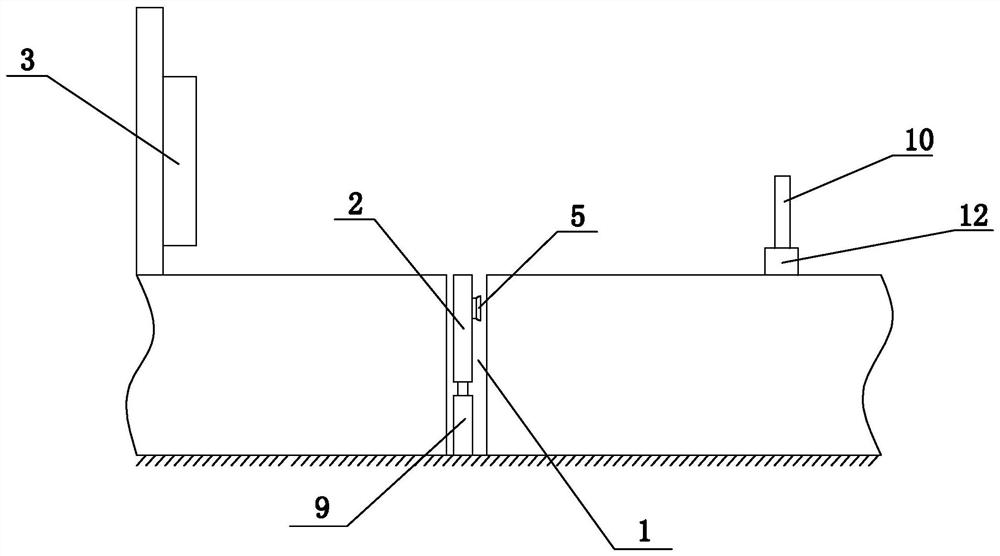

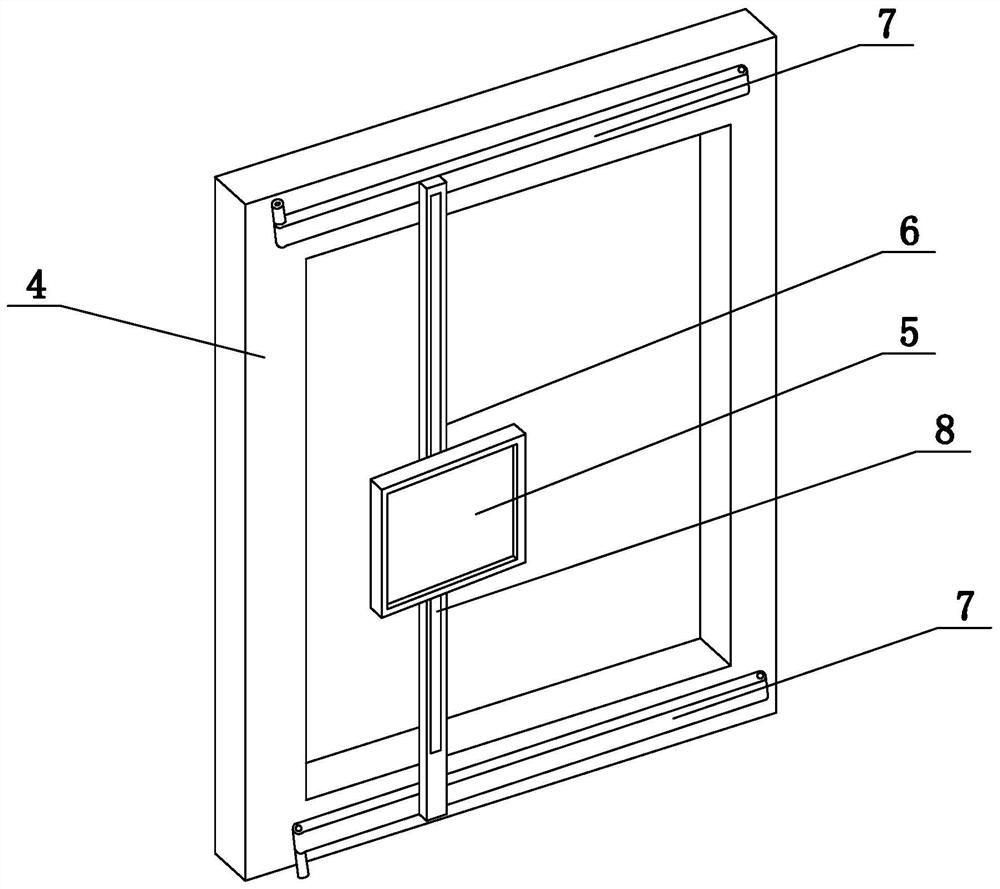

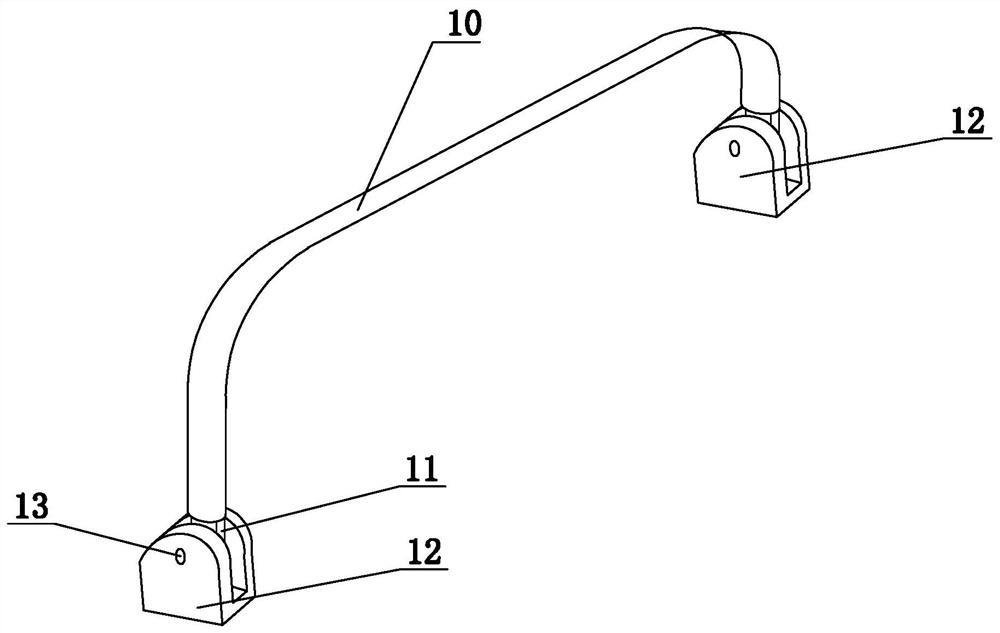

[0026] For details, see Figure 1 to Figure 6 :

[0027] A motor vehicle headlight detection system, which includes an installation groove 1 set on the ground of the detection area, a shielding device 2 that can be lifted and lowered in the installation groove 1, a headlight detector 3 located in front of the shielding device 2, and a wire And the controller, the shading device 2 includes a mounting frame 4, a shading plate 5 and a two-dimensional driving device, the two-dimensional driving device includes a vertically arranged mounting rod 6, and is horizontally arranged on the mounting frame 4 for driving the mounting rod 6 to move laterally The first synchronous belt drive assembly 7, the second synchronous belt drive assembly 8 arranged on the installation rod 6 for driving the vertical movement of the light shield 5, the two ends of the installation rod 6 are respectively connected with the first synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com