Electric welder provided with multiple welding heads

An electric welding machine and multi-welding head technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as affecting production efficiency, slow speed, and inability to meet rapid production, so as to improve efficiency and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

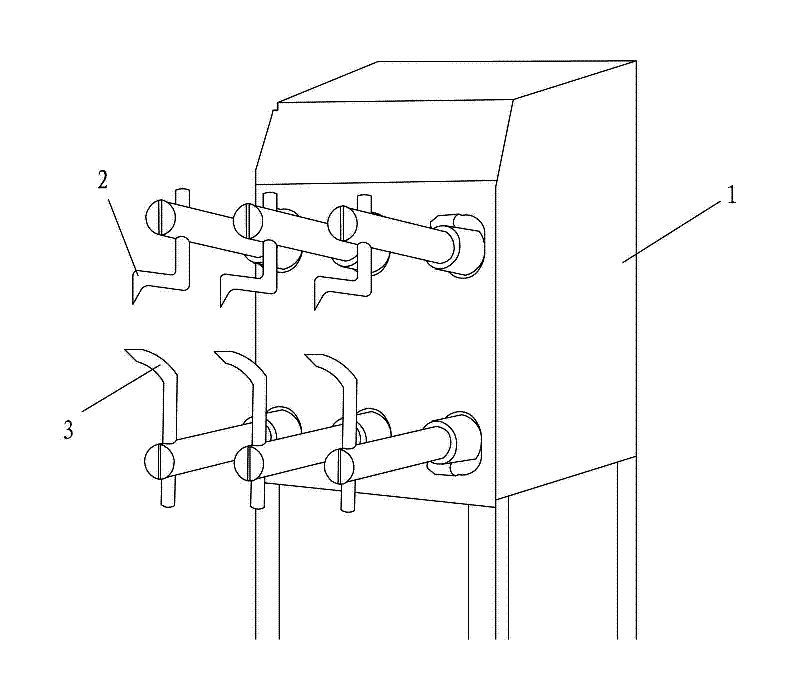

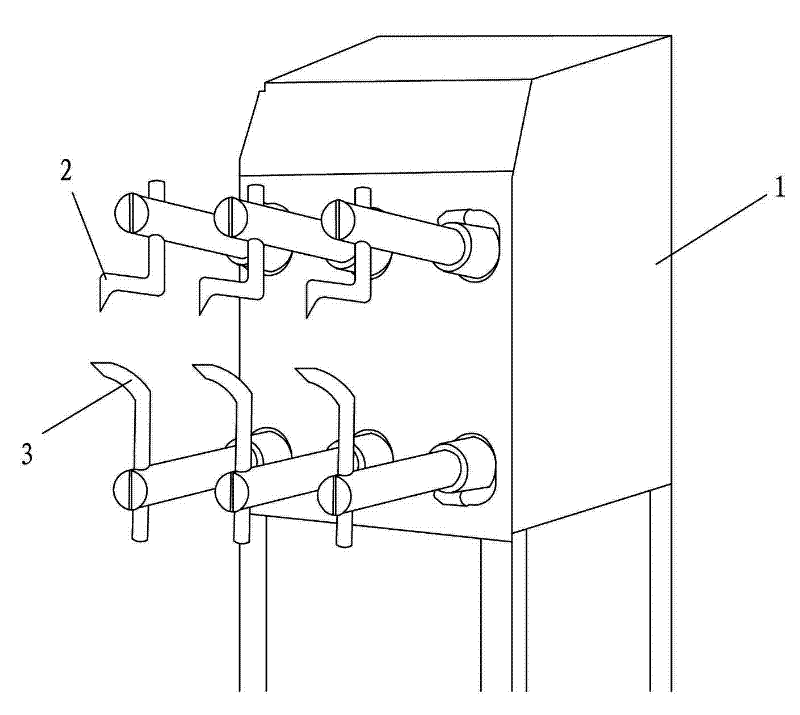

[0011] refer to figure 1 , the preferred embodiment of the present invention is a multi-welding head electric welding machine, which is used for welding the LED ceiling light box. The hot spot welding head 2 and the electric hot spot welding head 2 are arranged in parallel on the chassis 1, and the corresponding electric hot spot welding head 2 on the chassis 1 is also provided with a support frame 3 for supporting objects below.

[0012] When performing light box welding, place the light box frame on the support frame 3, start the power supply, and when the electric hot spot welding head 2 heats up, press the control button to operate a plurality of electric hot spot welding heads 2 arranged in parallel to perform spot welding at the same time, and raise the light box. The welding speed can effectively improve the production efficiency.

[0013] The above descriptions are only the preferred implementation modes of the present invention, as long as the technical solutions to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com