Compensating winding system of power transformer with single-phase four-column iron core structure

A technology for power transformers and compensation windings, applied in the direction of transformers/inductor coils/windings/connections, transformers, fixed transformers, etc., can solve problems such as increased load loss of power transformers, and achieve the effect of suppressing additional magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

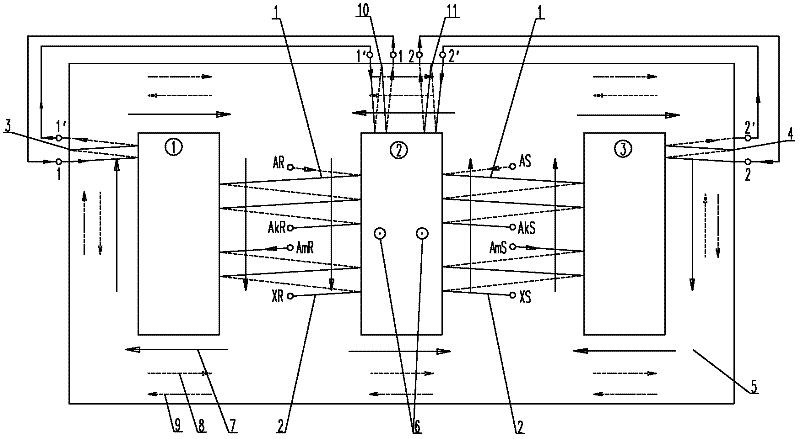

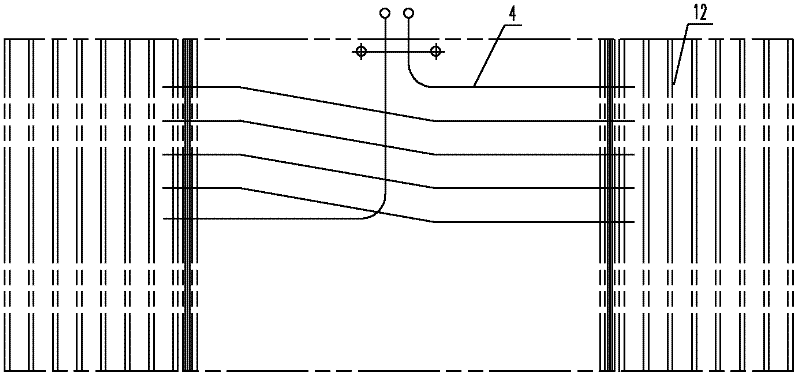

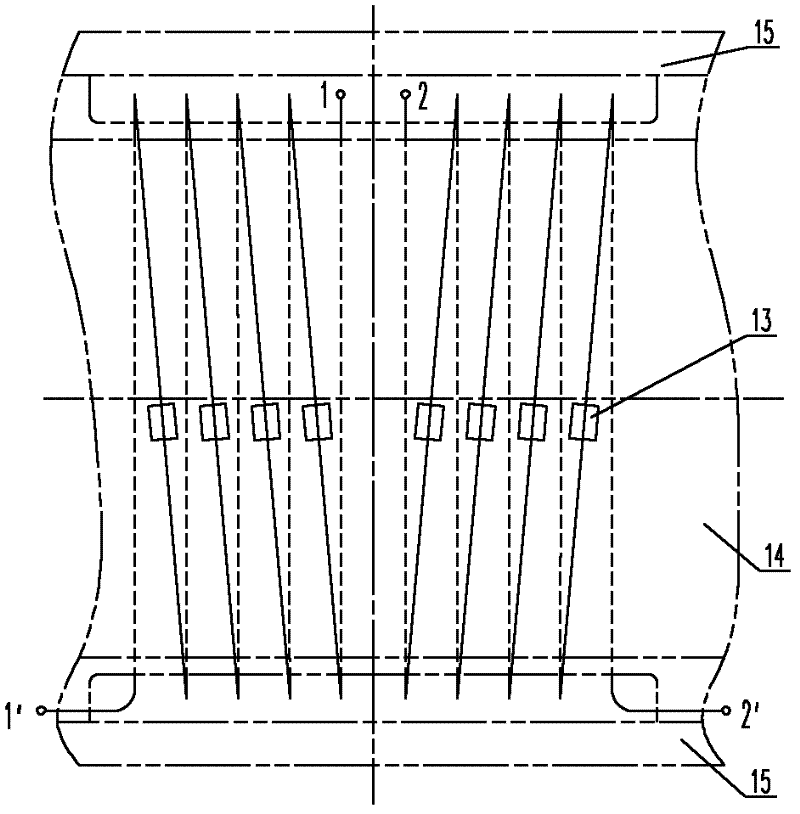

[0018] The compensation winding system of the power transformer with single-phase four-column core structure of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0019] see Figure 1 to Figure 4 As shown, the compensation winding system of the power transformer of the single-phase four-column core structure of the present invention includes the left compensation winding 3 and the right compensation winding 4 of the side columns on the left and right sides and the left compensation winding 10 and the right compensation winding 11 on the iron yoke, a total of four The four compensating windings are combined in pairs, specifically: the outlet ends of the left compensating winding 3 of the side columns on both sides are connected with the outlet ends of the left compensating winding 10 on the iron yoke to form a group, and the right sides of the side columns on both sides The outlet end of the compensation winding 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com