Axial turbomachine rotor having blade cooling

An axial-flow turbine and rotor technology, which is applied to the support elements of blades, mechanical equipment, engine elements, etc., can solve the problems of expensive manufacturing and installation of additional components, and achieve the effect of saving resources, high service life, and effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

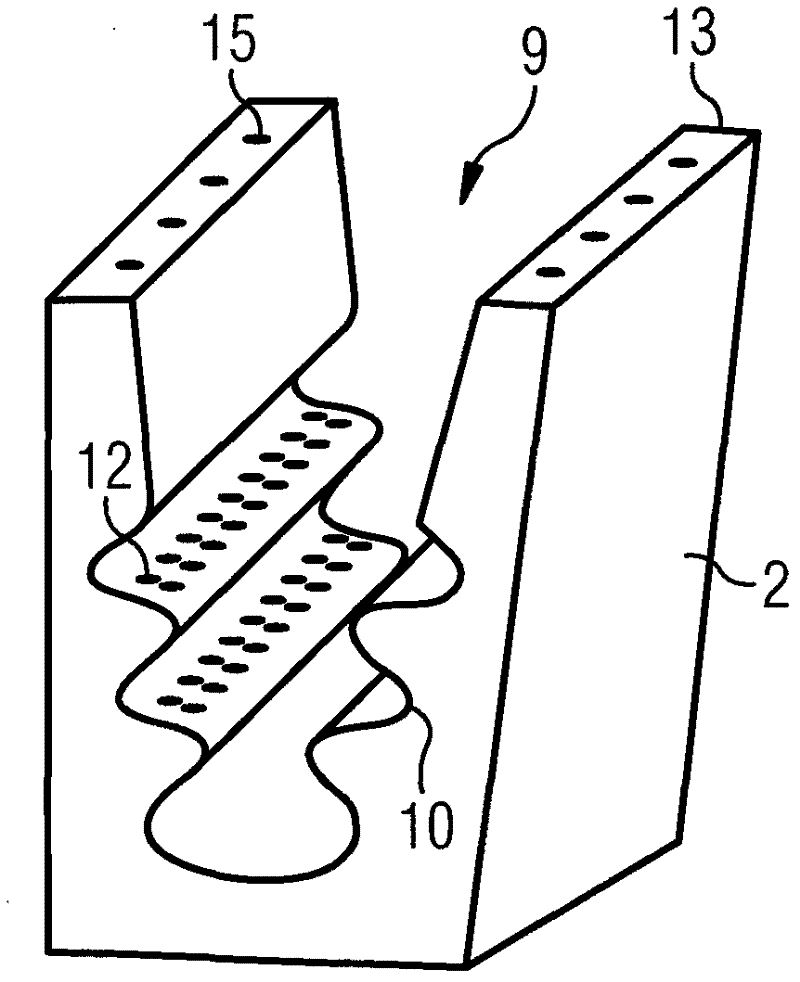

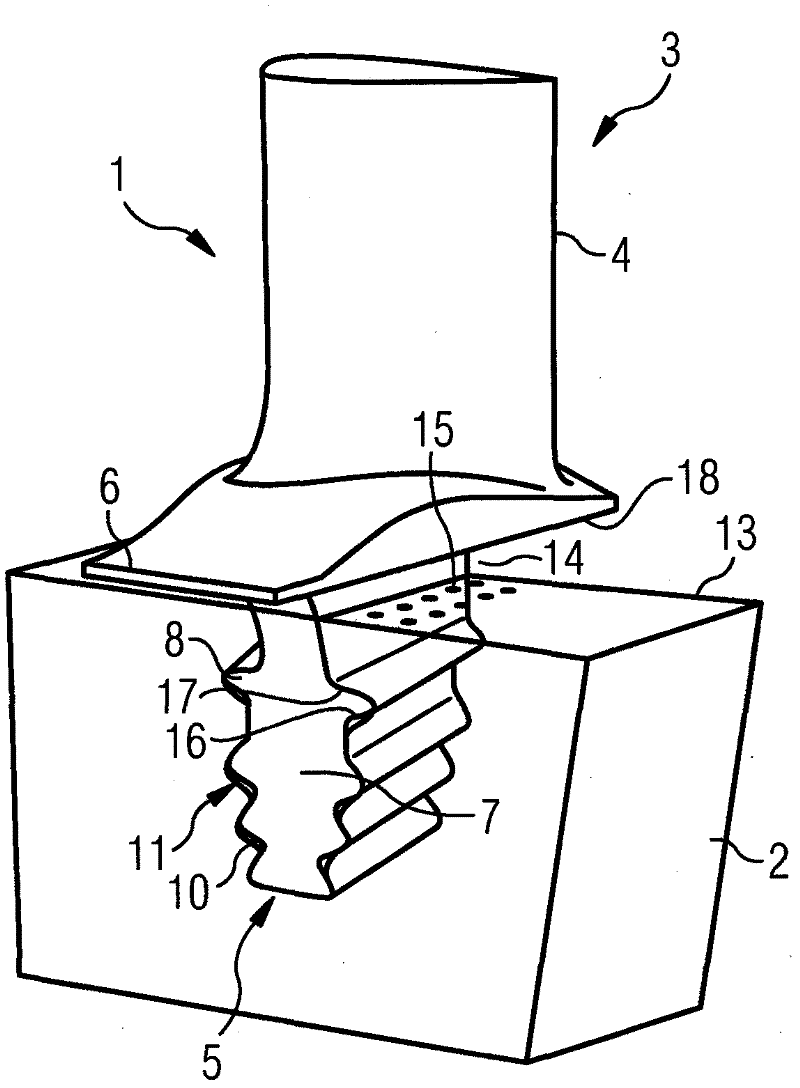

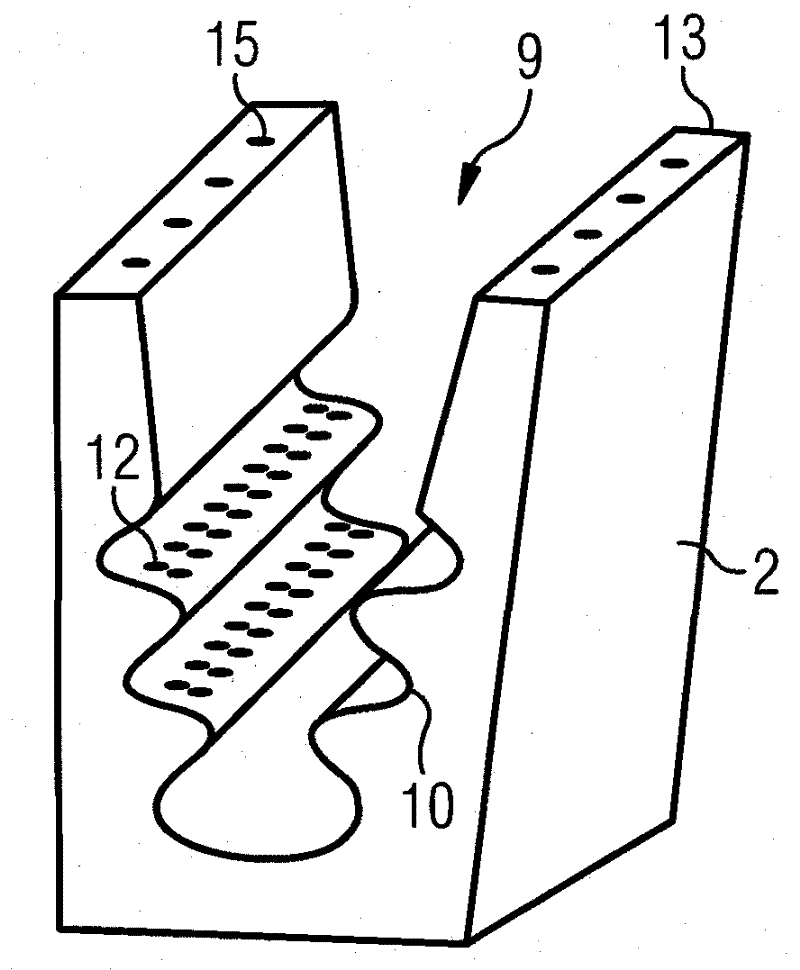

[0013] as in figure 1 and 2 As can be seen in the figure, the axial turbine rotor 1 has a disk arranged rotationally symmetrically about the axis of rotation of the axial turbine rotor 1 . Arranged on the outer edge 13 of the disk 2 are a plurality of rotor blades 3 which adjoin over the circumference of the disk 2 , wherein the rotor blades 3 form a rotor blade ring. Each moving blade 3 has an airfoil 4 by means of which the moving blade 3 interacts with the working fluid of the axial turbine rotor 1 . The airfoil 4 is arranged radially outwardly on the disk 2 , wherein the moving blade 3 has a blade root 5 at the radially inner end of the airfoil 4 , by means of which the airfoil 4 is fastened to the disk. 2 on. Between the airfoil 4 and the blade root 5, a blade platform 6 is formed on the moving blade 3, said blade platform extending in the axial direction and the circumferential direction of the axial turbine rotor 1, wherein the radially outer side of the blade platfo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap