Laminated Iron Core

一种叠铁芯、铁芯的技术,应用在磁路形状/式样/结构、制造电动发电机、电气元件等方向,能够解决马达铁芯保持力下降、马达铁芯变形等问题,达到防止磁特性的劣化、压力加工容易、提高材料利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

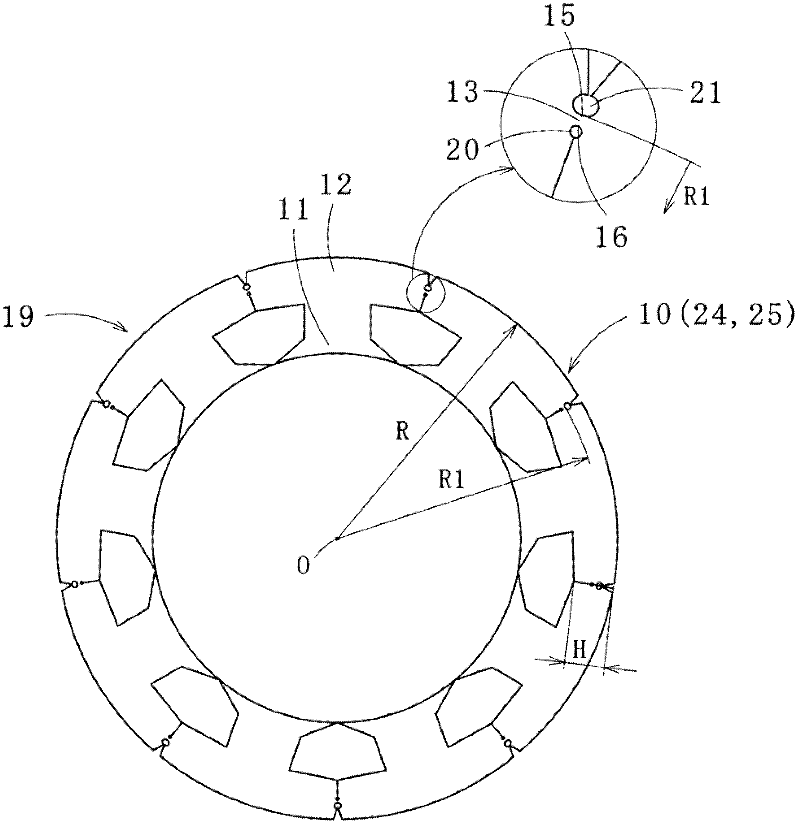

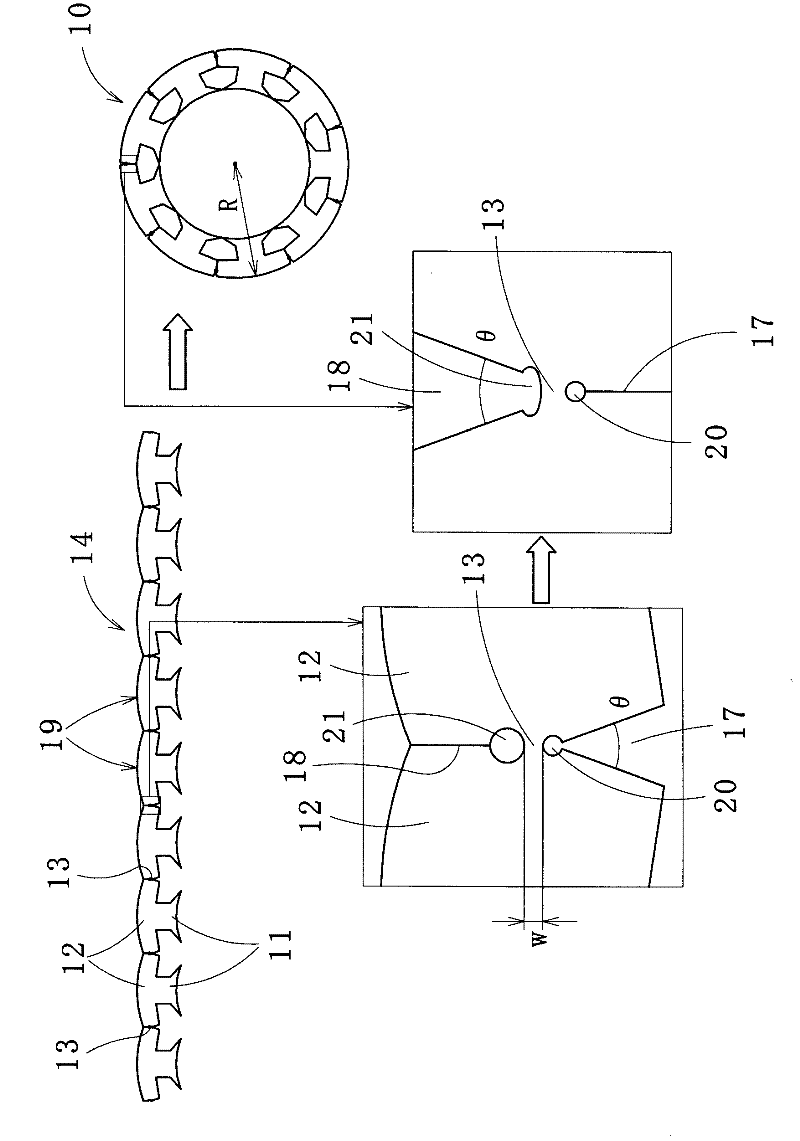

[0044] figure 1 A laminated iron core 10 according to a first embodiment of the present invention is shown. The laminated core 10 is the stator core of the motor, such as figure 2 As shown, the linear connection split core piece 14 connects the plurality of split yoke pieces 12 divided for each magnetic pole piece 11 with the bendable connection portion 13 , and the linear connection split core piece 14 A predetermined number of sheets are stacked, and the connecting portion 13 is bent to form a ring shape.

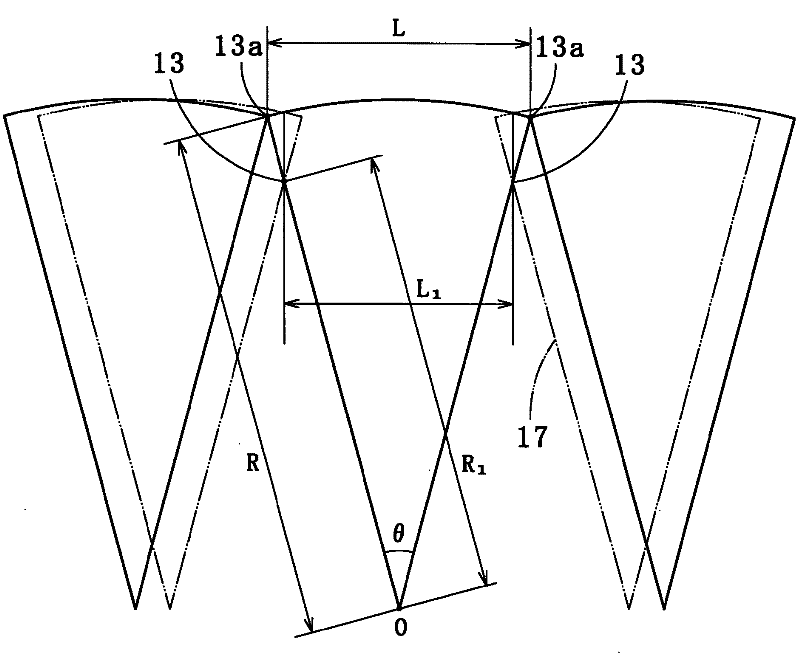

[0045] here, as figure 1 , figure 2 As shown, the radially outer position 15 of the connection portion 13 is at least 3% (preferably at least 5%, more preferably at least 10%) of the radius R of the laminated core 10 inwardly. In addition, the radially inner position 16 of the connecting portion 13 is located away from the inner position of the divided yoke piece 12 to the outside by more than 40% (preferably 50% or more) of the width H of the divided yoke piece 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com