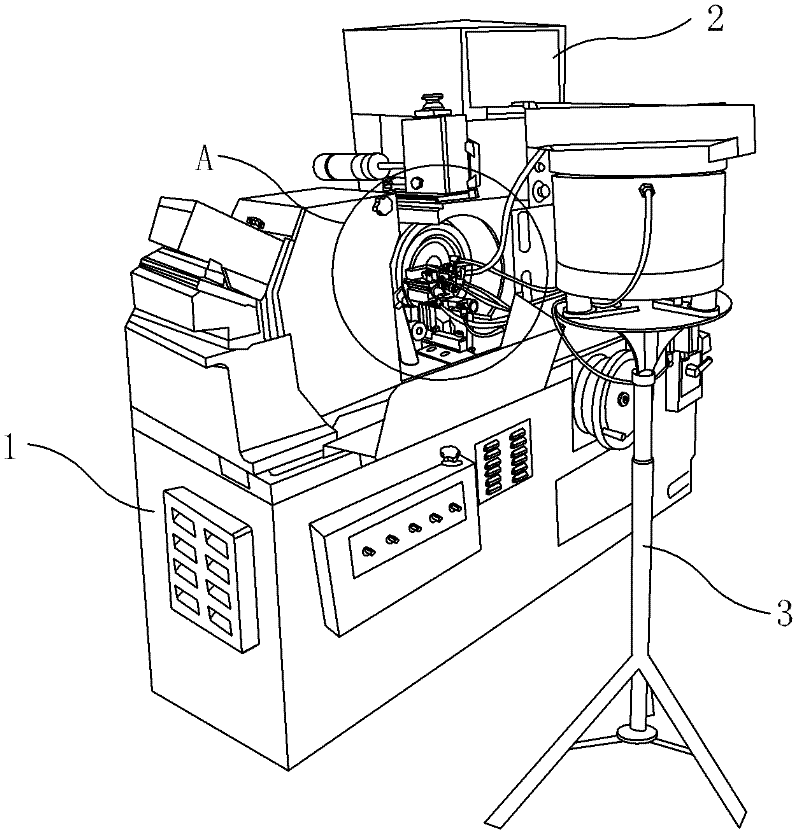

Automatic feeder machine for grinding machine and processing method thereof

A technology of automatic feeding and grinding machine, which is applied in grinding machines, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc. The method is feasible, the degree of automation is high, and the effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

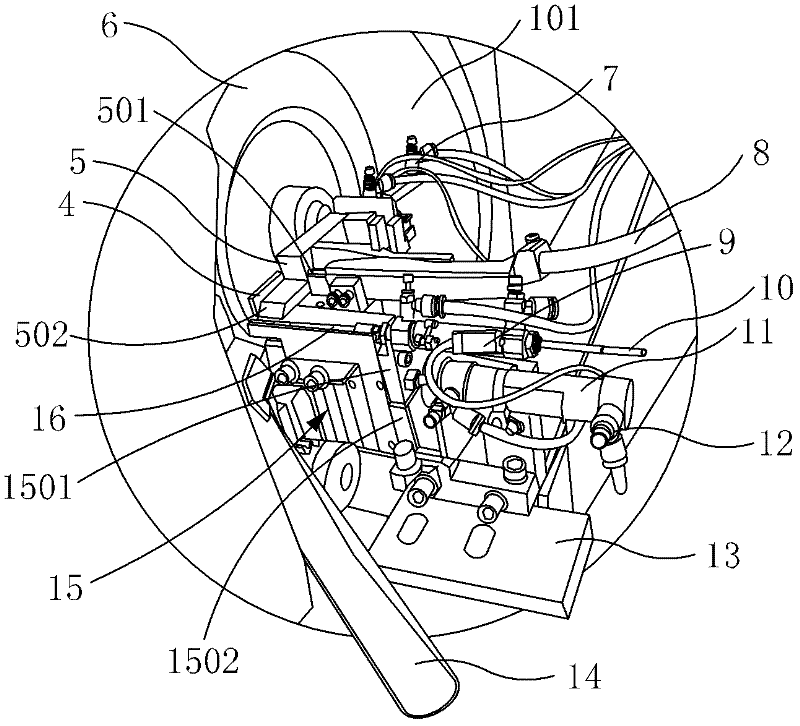

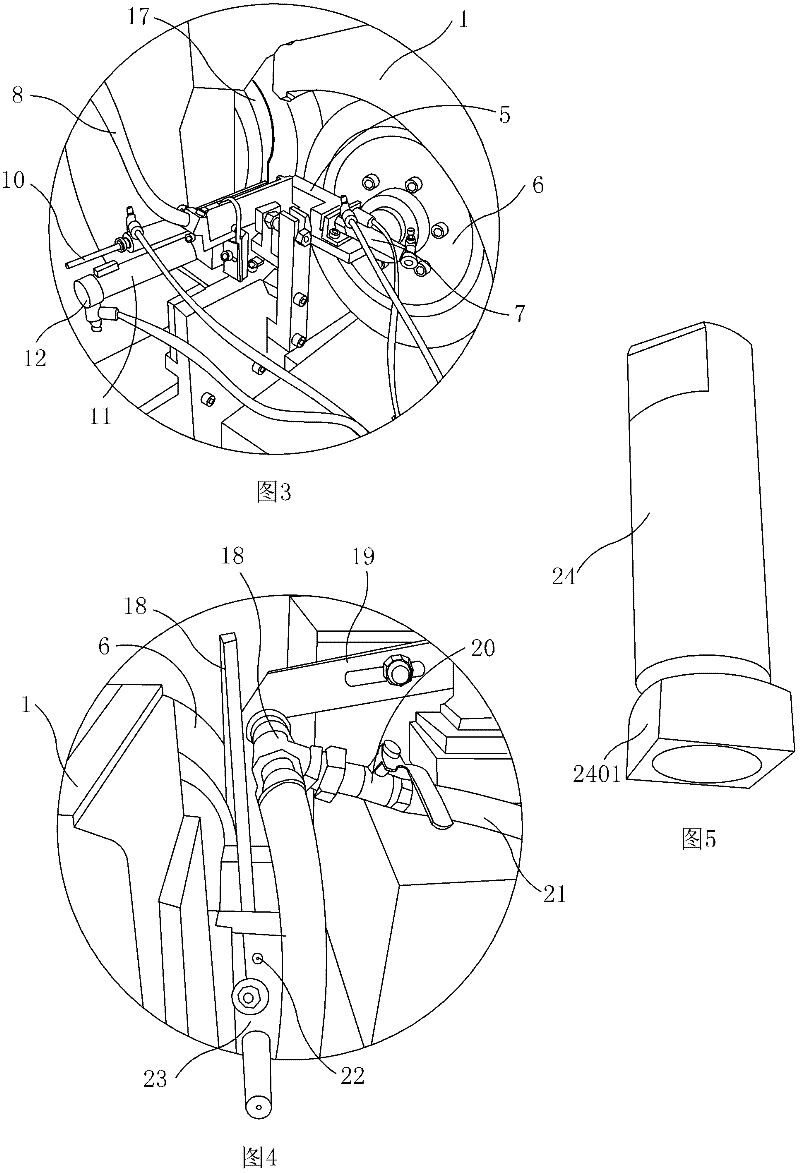

[0018] Now take the present invention of LT-MC03 model as an example in conjunction with the accompanying drawings, and further describe its structure and use. Such as figure 2 , image 3 As shown, the baffle plate 4, slider 5, third cylinder 7, second magnetic switch 9, second cylinder 10, first cylinder 11, first magnetic switch 12, discharge chute 14, machine Base 15 and feed ejector rod 16 are connected as a whole, the base is slidably matched by upper base 1501 and lower base 1502, the lower base of the base is arranged on the front portion of the machine tool 1 through the fixed base plate 13, the upper machine base of the base The base is equipped with a first cylinder and a first magnetic switch, the feeding position of the upper machine base is equipped with a second air cylinder and a second magnetic switch, the processing side of the upper machine base is equipped with a slider, and the slider is equipped with a third cylinder. The material pipe 8 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com