Deburring machine negative pressure conveying platform special air valve and control method

A technology of conveying platform and deburring machine, which is applied in the direction of valve details, valve devices, mechanical equipment, etc. It can solve the problems of affecting the grinding effect, the workpiece cannot be fixed, and the negative pressure is reduced, so as to reduce processing costs, simple structure, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

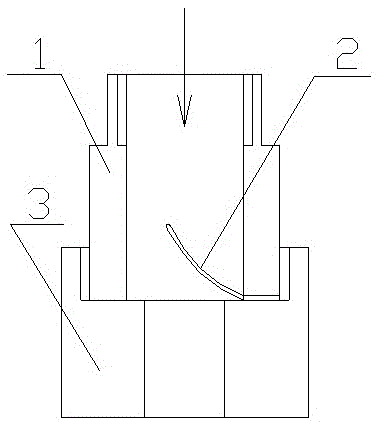

[0009] Embodiment 1: with reference to attached figure 1 . A special air valve for the negative pressure conveying platform of a sanding and deburring machine. The upper valve body 1 and the junction with the lower valve body 3 are provided with an elastic valve chip 2 for closing the passage of the upper valve body cavity and the lower valve body cavity, and the elastic valve chip 2 is in the In the non-working state, it is in the normally open state; the diameter of the valve cavity of the upper valve body 1 is larger than the diameter of the valve cavity of the lower valve body 3, and a sealing surface for the closing of the elastic valve chip 2 is formed around the valve port of the lower valve body 3, when the elastic valve chip When the 2 surfaces are joined with the sealing surfaces around the valve port of the lower valve body 3, the channel of the valve cavity of the upper valve body 1 and the channel of the valve cavity of the lower valve body 3 are closed, and the a...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, an automatic control method for the special air valve of the negative pressure conveying platform of a sanding and deburring machine, when there is no workpiece at the port 1 of the upper valve body, the negative pressure suction from the port of the lower valve body will The elastic valve chip 2 is attracted to the sealing surface around the valve port in the inner cavity of the lower valve body 3. At this time, the air flow channel between the upper valve body cavity and the lower valve body cavity is closed by the elastic valve chip 2, and no negative pressure air flow is generated at the upper valve body port ; When there is a workpiece at the upper valve body port, the negative pressure airflow from the lower valve body port makes the upper valve body cavity and the lower valve body cavity form a vacuum state, the elastic valve chip 2 is in an open state, and the negative pressure airflow from the lower valve body port acts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com