A balance test system for vehicle brake discs

A technology of balance testing and vehicle braking, which is applied in the field of dynamic balance, and can solve problems such as physical injury, affecting the weight removal accuracy of ventilated brake discs, and thicker surface coverage of brake discs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

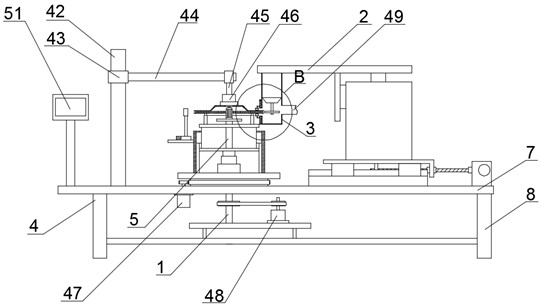

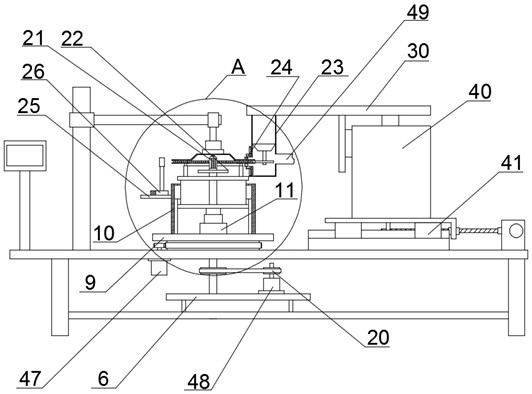

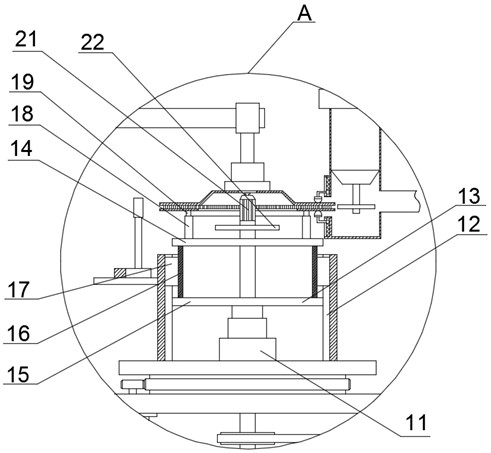

[0030] Such as Figure 1 to Figure 5 As shown, the present embodiment is used for a balance test system of a vehicle brake disc, including a balance detection module 1, a weight removal correction module 2 and a collection module 3, and the balance detection module 1 is used for performing balance detection on a ventilated brake disc, and weight removal The correction module 2 is used to deweight the unbalanced ventilated brake disc by milling, and the collection module 3 is used to recover the ventilated brake disc remaining in the ventilated brake disc air duct and the ventilated brake disc during the milling deweighting correction. metal debris on the surface of the disk, the balance detection module 1 includes a workbench 4, a spindle 5 and a detection part 6, the workbench 4 includes a table 7 and a bracket 8, a turntable 9 is arranged on the table 7, and a controller 51 is installed on the table 7 , the upper surface of the turntable 9 is provided with a cylinder 10, the...

Embodiment 2

[0042] The parts in this embodiment that are the same as those in Embodiment 1 will not be repeated, and the difference lies in the working process of the vehicle brake disc balance testing system of the present invention.

[0043] Step 1. After energizing the equipment, pass the central hole of the ventilated brake disc through the upper end of the main shaft 5 and place the ventilated brake disc on the upper surface of the first flange 22 on the main shaft 5;

[0044] Step 2: After inputting the clamping command to the controller 51, the controller 51 instructs the clamping device 21 on the upper end of the main shaft 5 to cooperate with the central hole of the ventilated brake disc to clamp the ventilated brake disc;

[0045] Step 3: After inputting the detection instruction to the controller 51, the controller 51 will instruct the second motor 48 in the balance detection module 1 to run and drive the main shaft 5 to rotate to perform balance detection on the ventilated brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com