Vacuum working platform composed of special air valve for deburring machine and negative pressure control method

A deburring machine and working platform technology, which is applied in the direction of manufacturing tools, metal processing equipment, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems that workpieces cannot be fixed, affect the grinding effect, and reduce negative pressure, etc., and achieve structural Simple, reduce processing costs, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

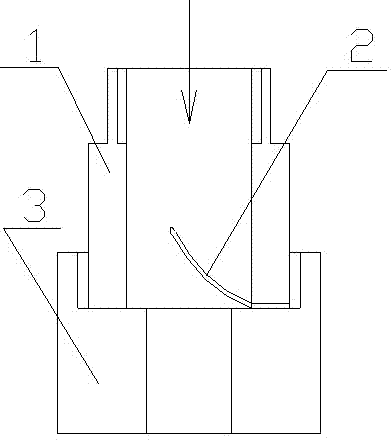

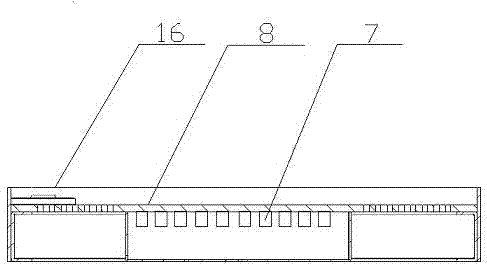

[0013] Embodiment 1: with reference to attached figure 1 and 2 . A vacuum working platform composed of special air valves for deburring machines, which includes a vacuum working platform for deburring machines, a plurality of negative pressure suction holes are opened on the table surface of the vacuum working platform 8 of the deburring machine, and the negative pressure suction An air valve 7 is installed on the back of the hole, and the upper valve body 1 of the air valve and the junction with the lower valve body 3 are provided with an elastic valve chip 2 for closing the passage of the upper valve body cavity and the lower valve body cavity, and the elastic valve chip 2 is in the non-working state. It is in the normally open state; the diameter of the valve cavity of the upper valve body 1 is smaller than the diameter of the valve cavity of the lower valve body 3, and a sealing surface for the closing of the elastic valve chip 2 is formed around the valve port of the low...

Embodiment 2

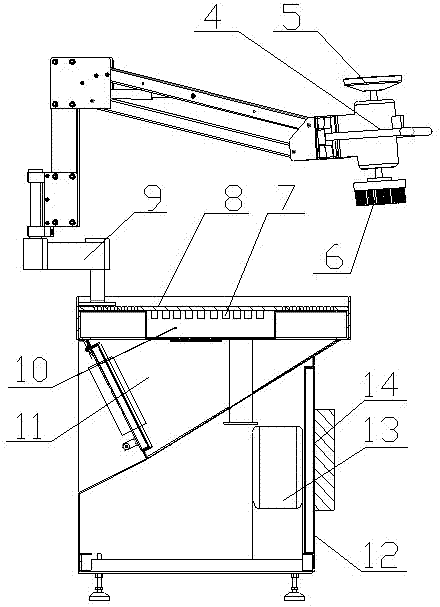

[0014] Embodiment 2: with reference to attached figure 1 and 3 -4. On the basis of Embodiment 1, a deburring machine composed of a special vacuum working platform for deburring machines, which includes a deburring machine, the lower end of the rocker arm 9 is in rotation and plugged with the vacuum working platform 8 tables, and the biaxial motor 15 The handle assembly 4 is installed at the end of the rocker arm, and the handle assembly 4 is connected with the central axis and the hole at the end of the rocker arm. The handle assembly 4 can rotate 360 degrees around the center of the end of the rocker arm, and can rotate at 45°90 ° and 180° position quick lock. Sand sheet brush head 5 and polishing brush plate 6 are respectively equipped with at the two ends of biaxial motor 15, and a plurality of negative pressure suction holes are arranged on the table top of the vacuum work platform in the described deburring machine, and the negative pressure suction holes are installe...

Embodiment 3

[0015] Embodiment 3: On the basis of Embodiments 1 and 2, a negative pressure control method of a vacuum work platform composed of a special air valve for deburring machines, when there is no workpiece at the port 1 of the upper valve body, the Negative pressure sucks the elastic valve chip 2 to the sealing table around the inner cavity of the lower valve body 3. At this time, the air flow channel between the upper valve body cavity and the lower valve body cavity is closed by the elastic valve chip 2, and the upper valve body port is closed. Negative pressure air flow is generated; when there is a workpiece at the upper valve body port, the negative pressure air flow from the lower valve body port makes the upper valve body cavity and the lower valve body cavity form a vacuum state, the elastic valve chip 2 is in the open state, and the negative pressure from the lower valve body port The compressed air flow directly acts on the workpiece through the negative pressure suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com