Transposition device for electronic elements

An electronic component and indexing technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of reducing use efficiency and component life, increasing volume, occupying space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

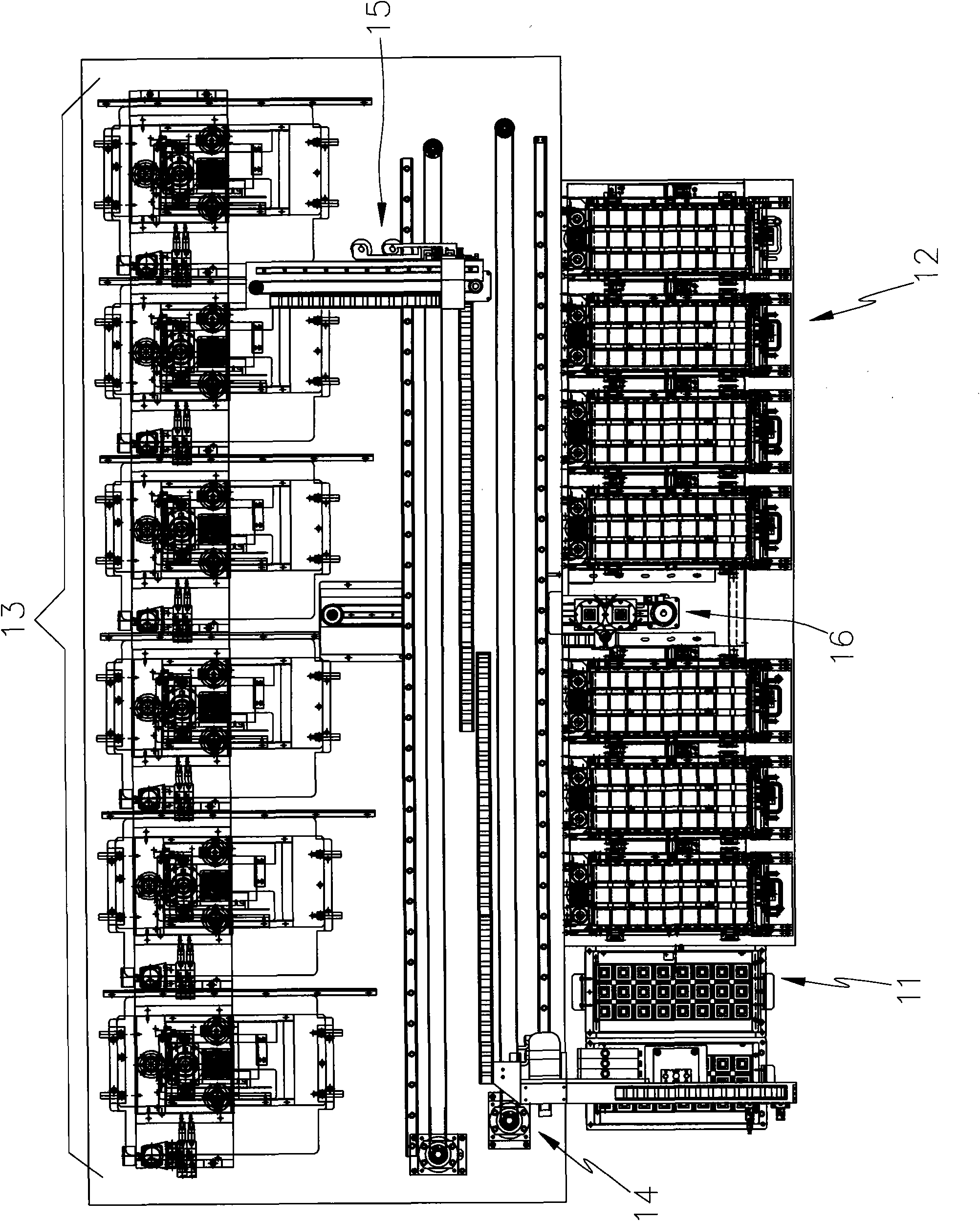

[0034] In order to enable your examiner to have a further understanding of the present invention, hereby cite a preferred embodiment together with the accompanying drawings, and describe it in detail as follows:

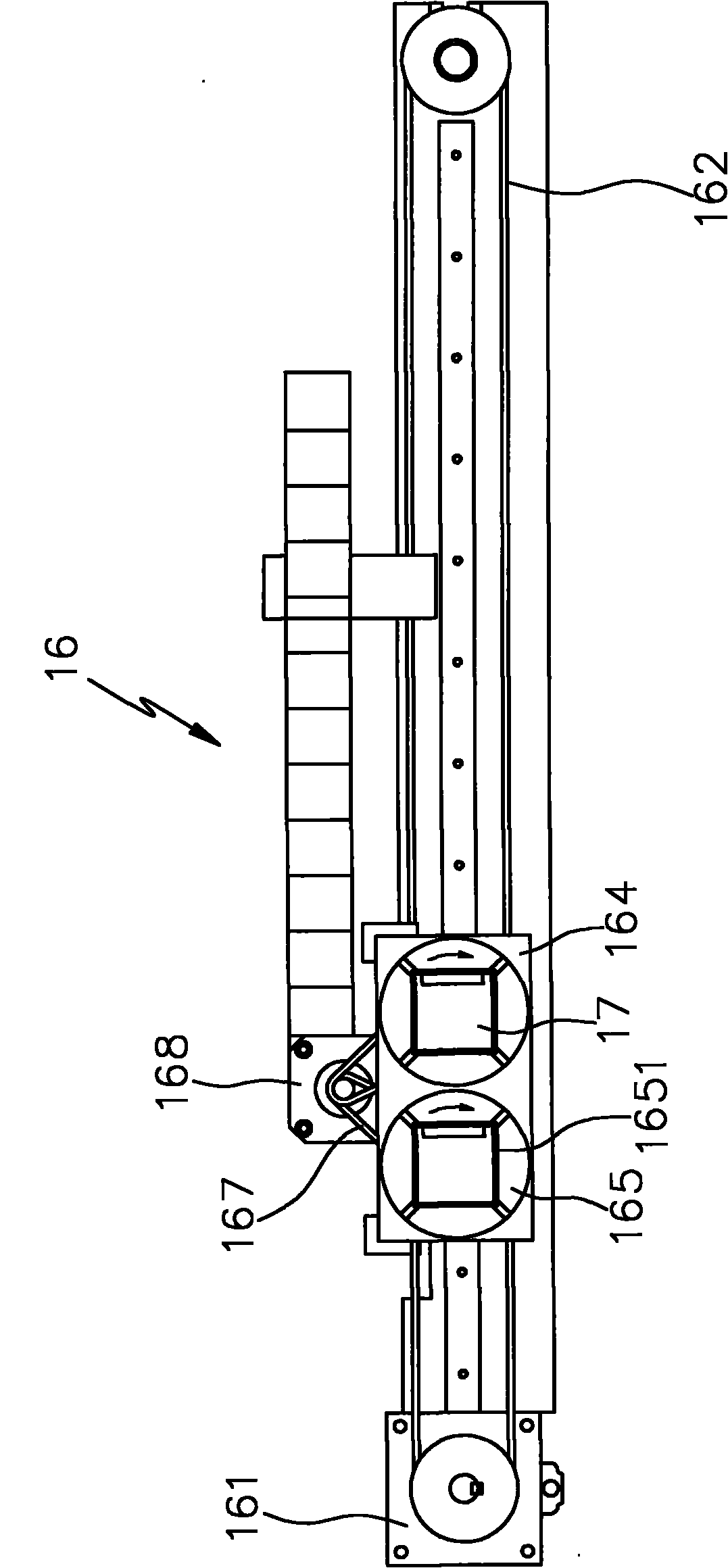

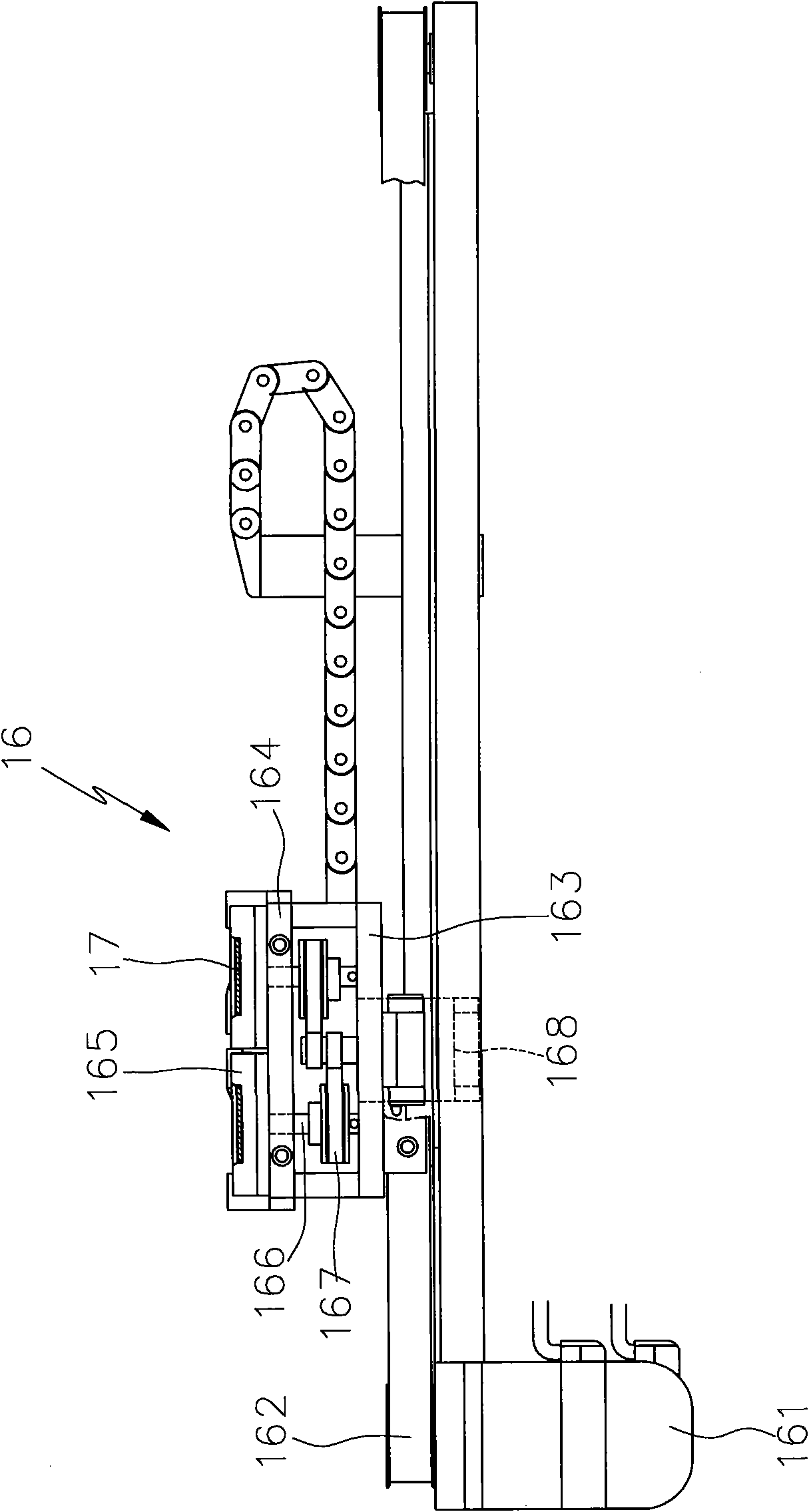

[0035] see Figure 4 , Figure 5 , Figure 6 and Figure 7, the indexing device 20 of the present invention is assembled on the machine platform, and includes an organic base 21, a bearing seat 22, a cover 23 and a sliding member 24, and the base 21 is provided with a plurality of positioning pins 211 and concave holes 212 on the top surface, Each positioning pin 211 is used to guide the pick-and-place device of the material transfer device (not shown) in alignment, so that the pick-and-place device can accurately pick and place electronic components, and the bottom surface of each concave hole 212 is equipped with a bearing 213. The bottom surface of the base 21 is provided with at least one chute 214, and the chute 214 is communicated with each concave hole 212....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com