Multicast detection device and method for full-depth tooth side face defects of bevel gear

A detection device and bevel gear technology, which is applied in the direction of optical testing for flaws/defects, etc., can solve problems such as inconvenient operation, high radiation hazards, and laborious, etc., and achieve the effect of achieving consistency, eliminating human factors, and high-precision real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings.

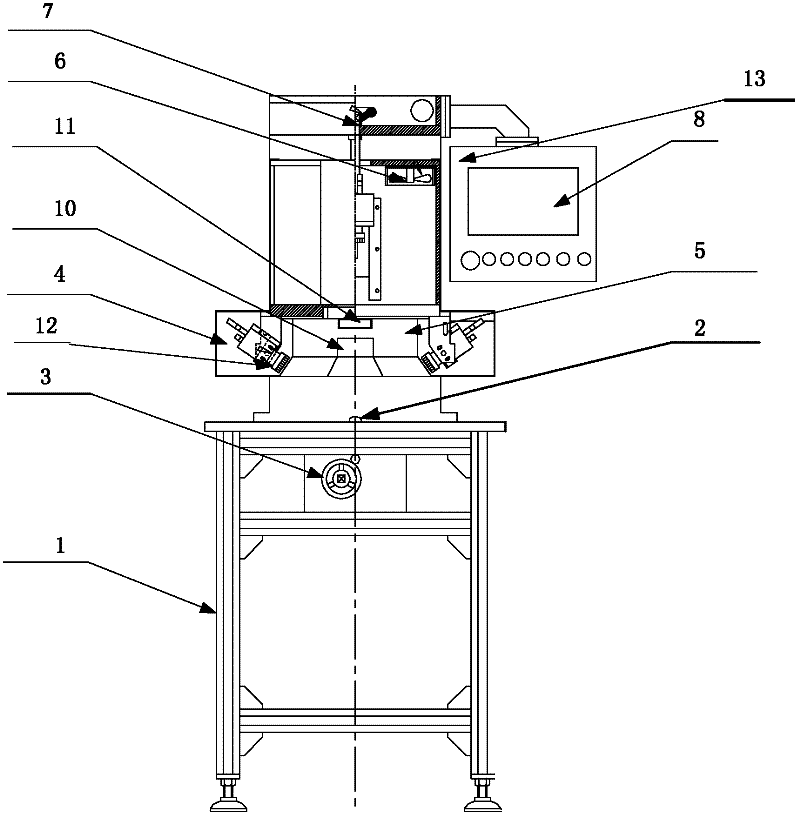

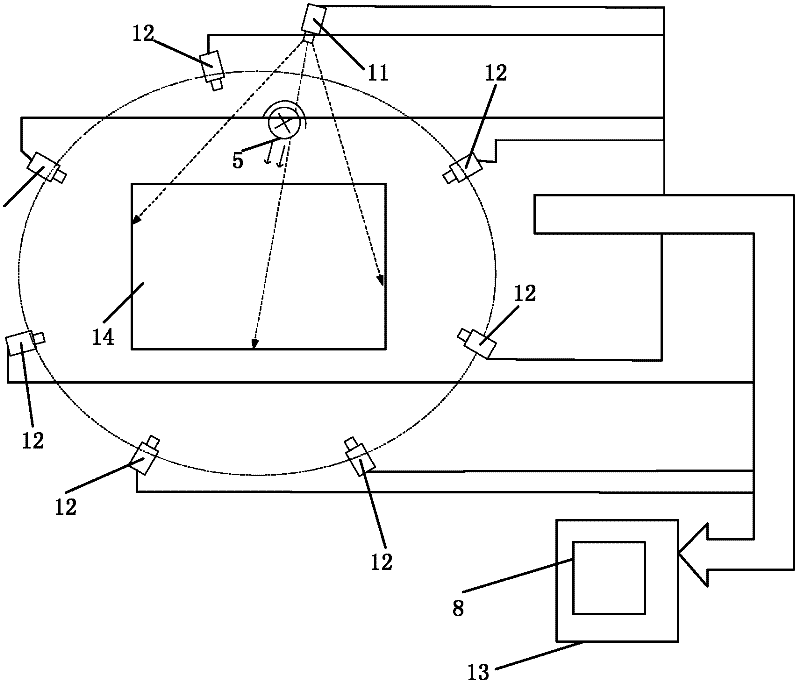

[0014] Such as figure 1 As shown, the bevel gear full-tooth side defect multi-eye detection device includes a frame group 1 with a frame type bottom, and a gear fixing device 2 is placed on the top surface of the frame group 1, and the gear fixing device 2 is the same as the frame group 1. The rotation transmission structure of the set angle division system 3 is connected, and the top of the gear fixing device 2 has a protrusion 10 that can adapt to the bevel gear to be tested in the shaft sleeve. The inner top of the photographic acquisition unit 4 is provided with a top camera 11 whose lens faces the protrusion 10, and the inner top of the photographic acquisition unit 4 is also provided with a highlight lighting unit 5. In addition, the interior of the photographic acquisition unit 4 is provided with a uniform surrounding distribution There are seven side ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com