Battery and steel shell thereof

A battery steel shell and battery technology, which is applied in the manufacture of alkaline batteries, battery pack components, alkaline batteries, etc., can solve the problems of positive tab bending, burning out, and battery scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

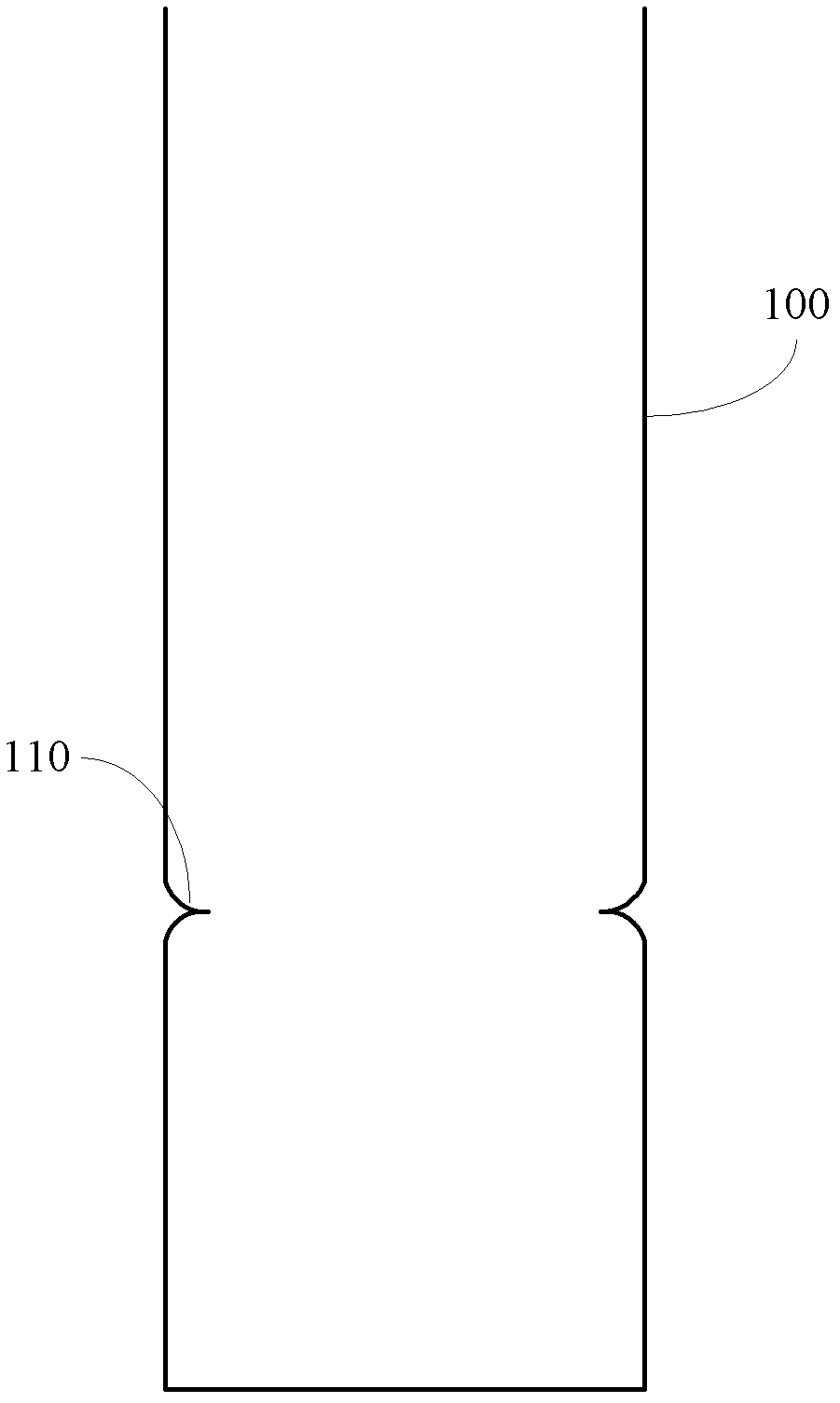

[0019] figure 1 It is a structural sectional view of the battery steel case in an embodiment. The battery steel case is used for accommodating the low electrode group of the battery, including the case 100 . The housing 100 is cylindrical with one end open and has an inner cavity, and the other end is a bottom cover. A holder 110 is disposed inside the housing 100 . The supporting member 110 protrudes from the inner wall of the casing 100 and is used to support the low electrode group of the battery, so as to reduce the distance between the top of the short electrode group and the open end of the steel case, thereby reducing the length of the positive electrode tab.

[0020] In this embodiment, the holding member 110 is 1 to 100 mm away from the bottom cover of the housing 100 to effectively support the short pole group, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com