Deflection-preventing axial pull-type gear box

A pull-out, wheel box technology is applied in the field of wheel boxes to achieve the effect of convenient operation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

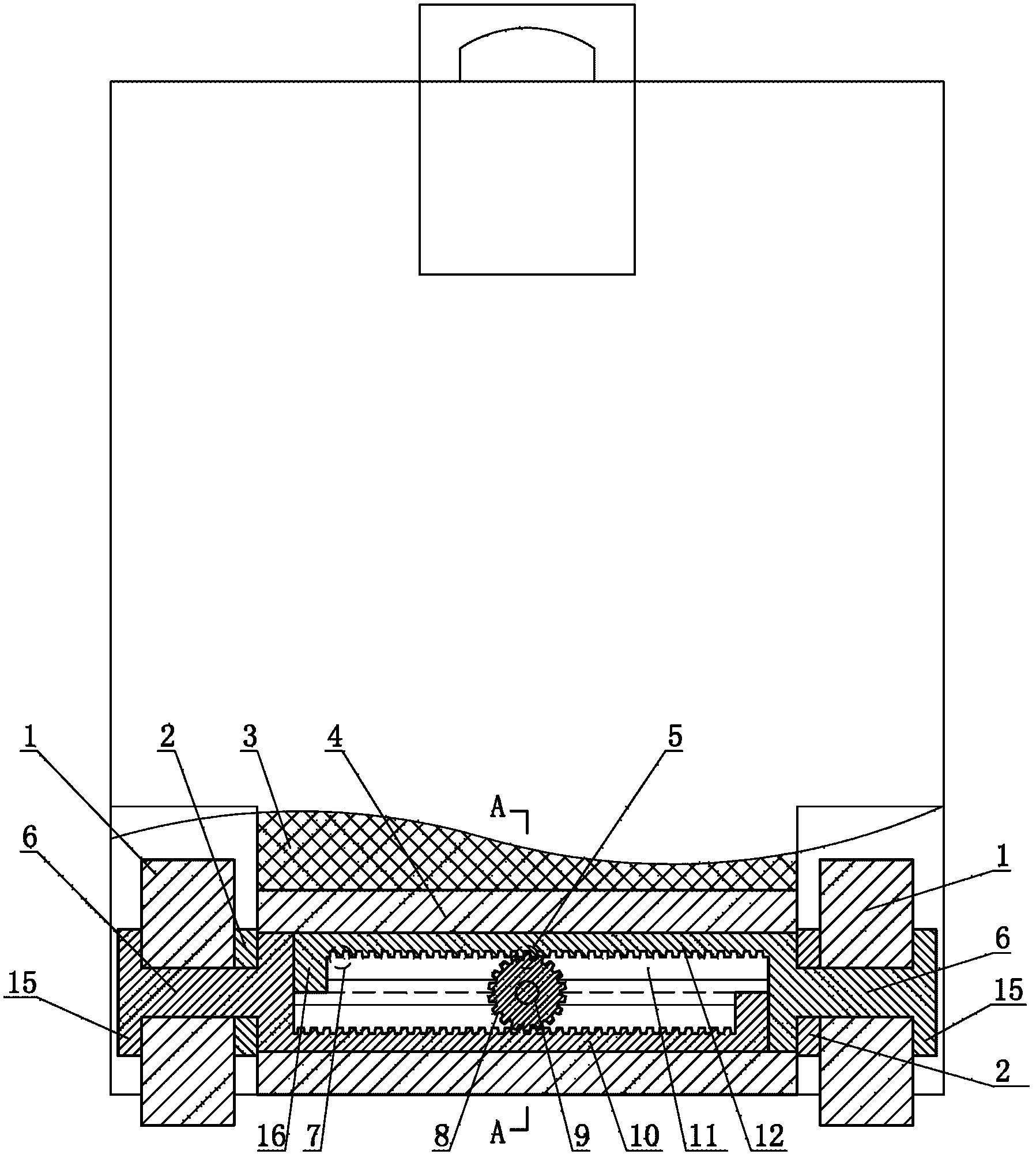

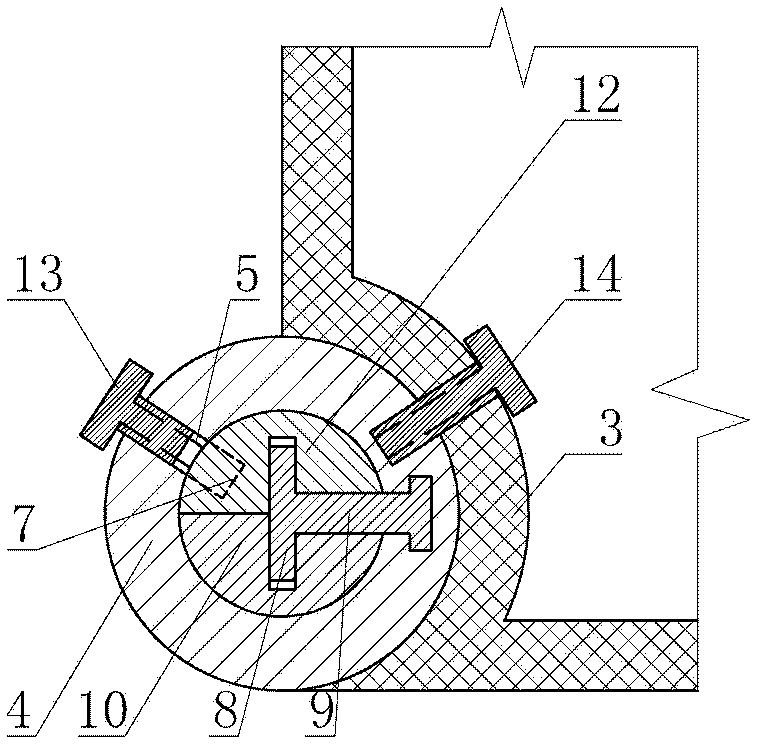

[0014] Anti-deflection axial pull-out wheel box, including roller 1, washer 2, box 3, shaft barrel 4, positioning hole 5, rotating shaft 6, shaft shank hole 7, gear 8, gear shaft 9, left shaft shank 10, tooth The slot 11 , the right shaft 12 , the positioning screw 13 , the fixing nail 14 , the rivet piece 15 and the blocking piece 16 are formed.

[0015] The shaft barrel 4 is a cylindrical body, the shaft barrel 4 is located at the bottom of the box body 3 and is connected with the box body 3 through the fixing nails 14 . There is a gear shaft 9 in the middle of the shaft barrel 4. One end of the gear shaft 9 is located in the blind hole of the inner side wall of the shaft barrel 4 and is in a rotating and dynamic fit with the shaft barrel 4. The other end of the gear shaft 9 is connected to the gear shaft 9. An integral and coaxial gear 8 . The semi-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com