Special numerically controlled lathe for cutting inner arc curved surface

A technology of CNC lathes and inner arcs, applied in automatic lathes/semi-automatic lathes, turning equipment, turning equipment, etc., can solve the problems of insufficient spindle speed, unstable machining accuracy, low cutting efficiency, etc., to improve work efficiency and Economic benefits, reducing labor intensity and improving processing efficiency

Inactive Publication Date: 2012-03-21

GUANGDONG UNIV OF PETROCHEMICAL TECH +1

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the former method is that the spindle speed is not high enough, and the mechanical control positioning has no feedback, so the machining accuracy is

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

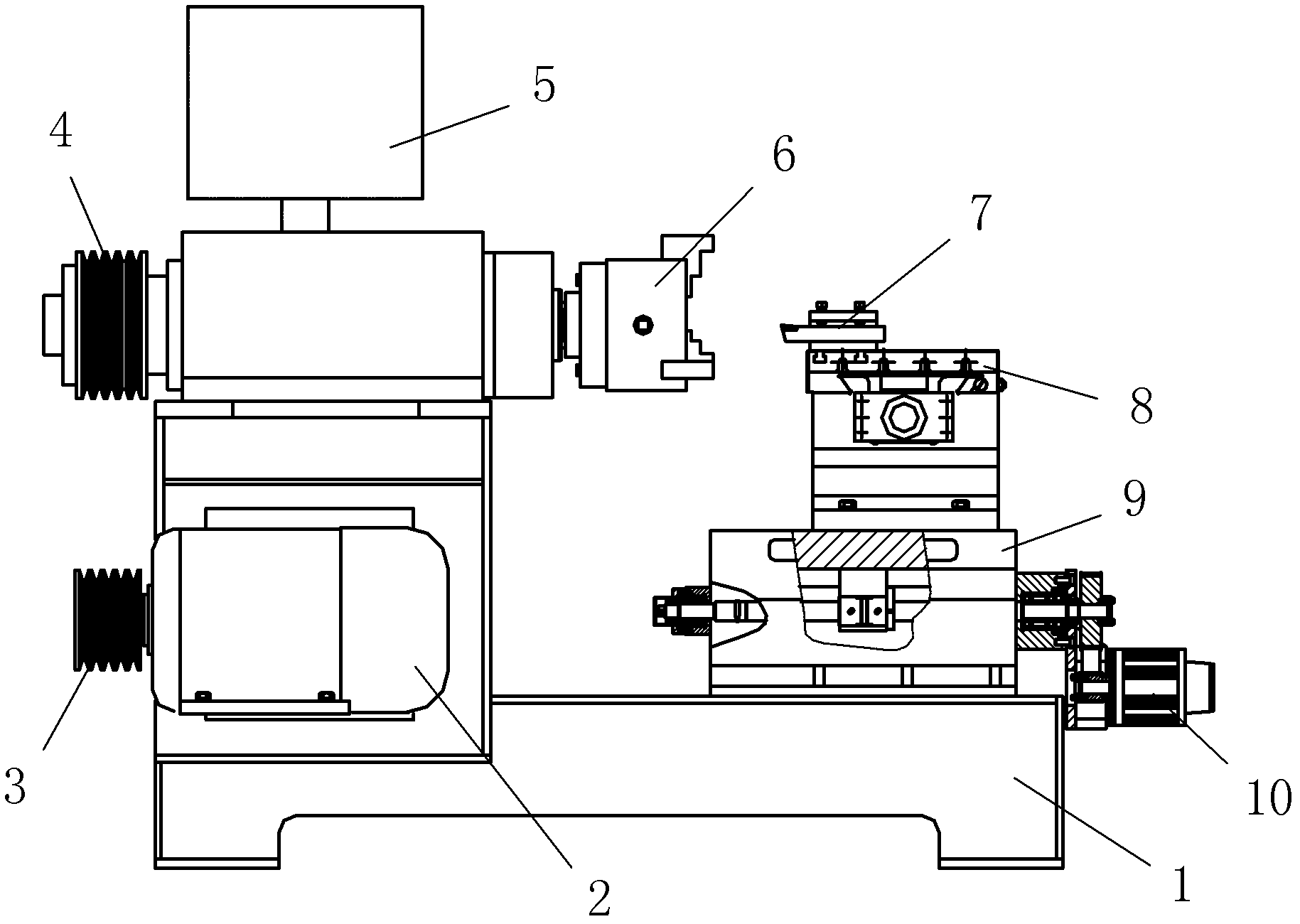

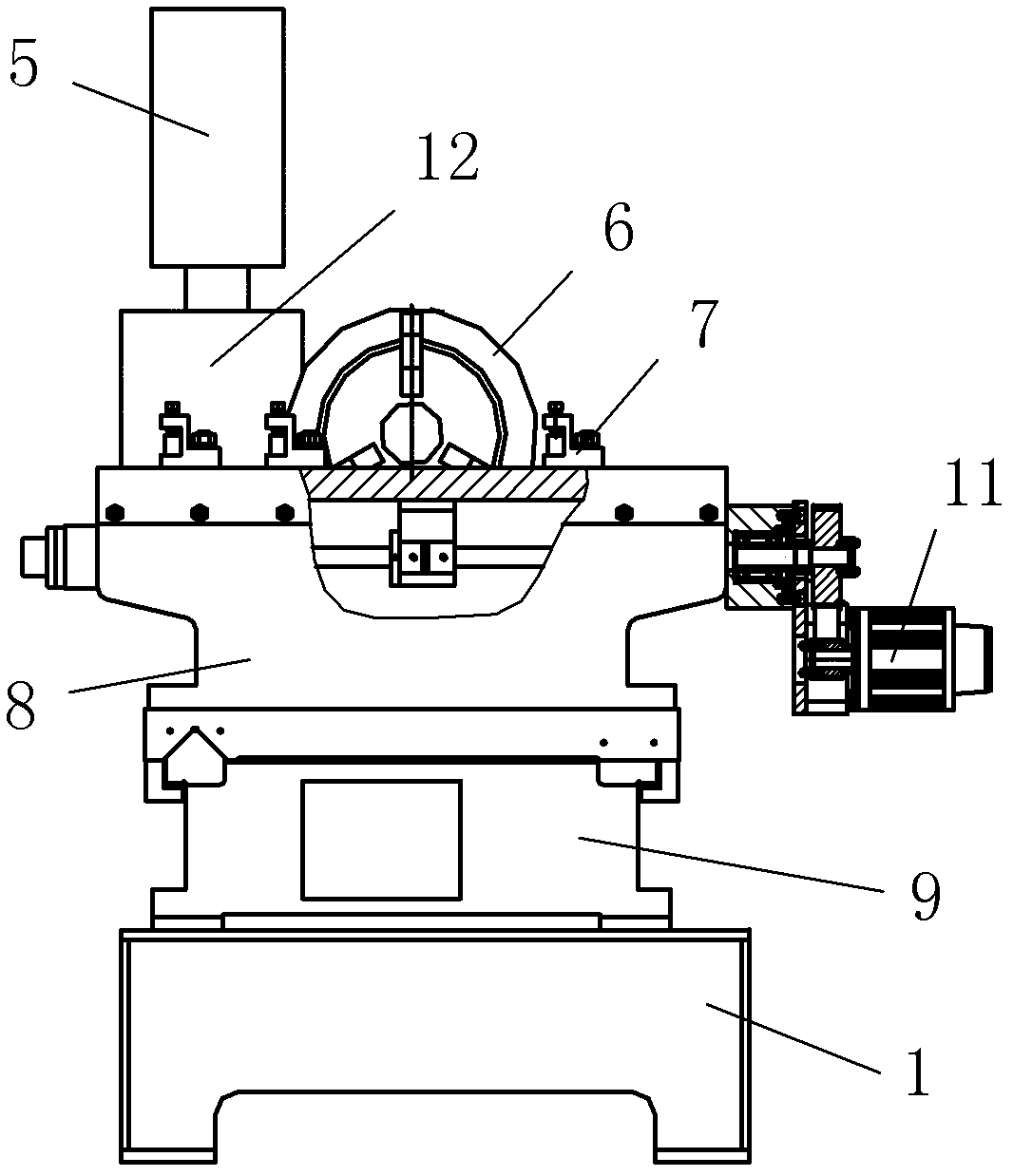

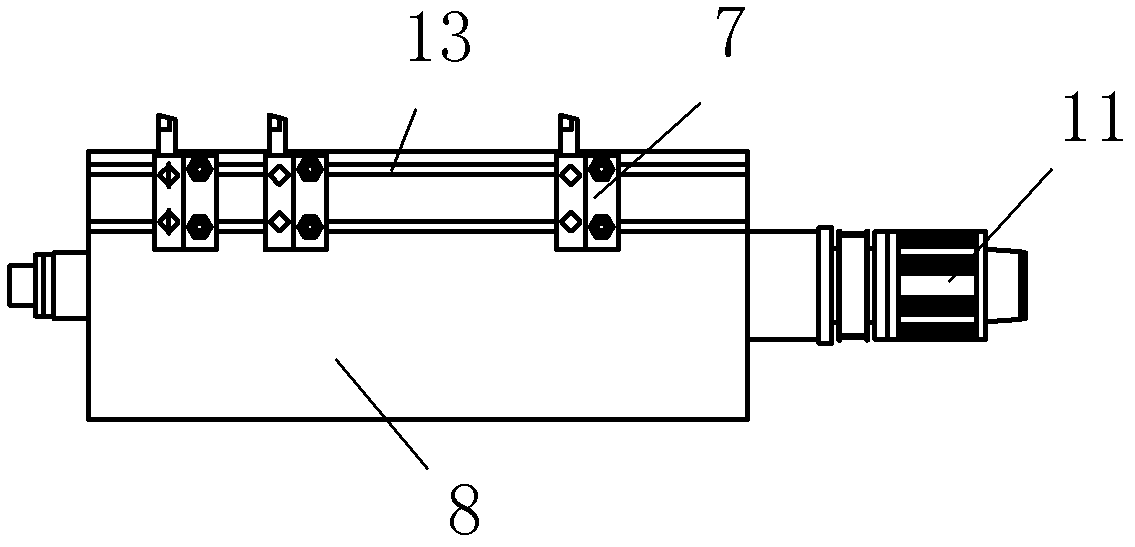

The invention discloses a special numerically controlled lathe for cutting an inner arc curved surface. The special numerically controlled lathe comprises a spindle driving component; a lower sliding seat (9) capable of moving along a Z axis is mounted on the upper surface of a lathe body rack (1); a tool apron (8) capable of moving along an X axis is mounted on the upper surface of the lower sliding seat (9); a Z axis feed servo driving mechanism (10) of the lower sliding seat (9) and an X axis feed servo driving mechanism of the tool apron (8) are arranged; and the tool apron (8) is provided with a row type tool rest device for clamping a tool. The special numerically controlled lathe disclosed by the invention has stable performance and high cutting efficiency, and can be used for efficiently cutting the inner arc curved surface workpieces which have various specifications and are made of various materials.

Description

technical field [0001] The invention belongs to the technical field of special-purpose numerical control machine tools, and specifically relates to a special numerical control lathe for efficiently cutting inner arc curved surfaces, mainly solving the problem of simultaneous clamping of multiple tools, shortening of the tool change stroke and time, and straight-line movement when turning inner arc curved surfaces efficiently. Knife instead of rotary tool change and other processing technology issues. Background technique [0002] Inner arc surface workpieces are widely used in home appliances, moulds, automobile manufacturing and other fields of society in my country. According to market research, only in the Zhanjiang area of Guangdong, the annual demand for rice cookers alone reaches 500 million, and the heating plate is a typical inner double arc surface. According to the shape characteristics of the inner arc surface workpiece, the main processing method is turning. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23B7/14B23B19/02B23B21/00

Inventor 陈银清任明蔡业彬李凯郑泽钿

Owner GUANGDONG UNIV OF PETROCHEMICAL TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com