Capping device of conduit mouth of ship body

A hull and driving device technology, applied in ships, door/window fittings, buildings, etc., can solve problems such as easy failure, difficult system measurement and control, complex structure of hull slot opening sealing device, etc., and achieve low cost and simple structure Reliable, easy to operate and maintain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment of the present invention and in conjunction with accompanying drawing, the present invention is further explained and described:

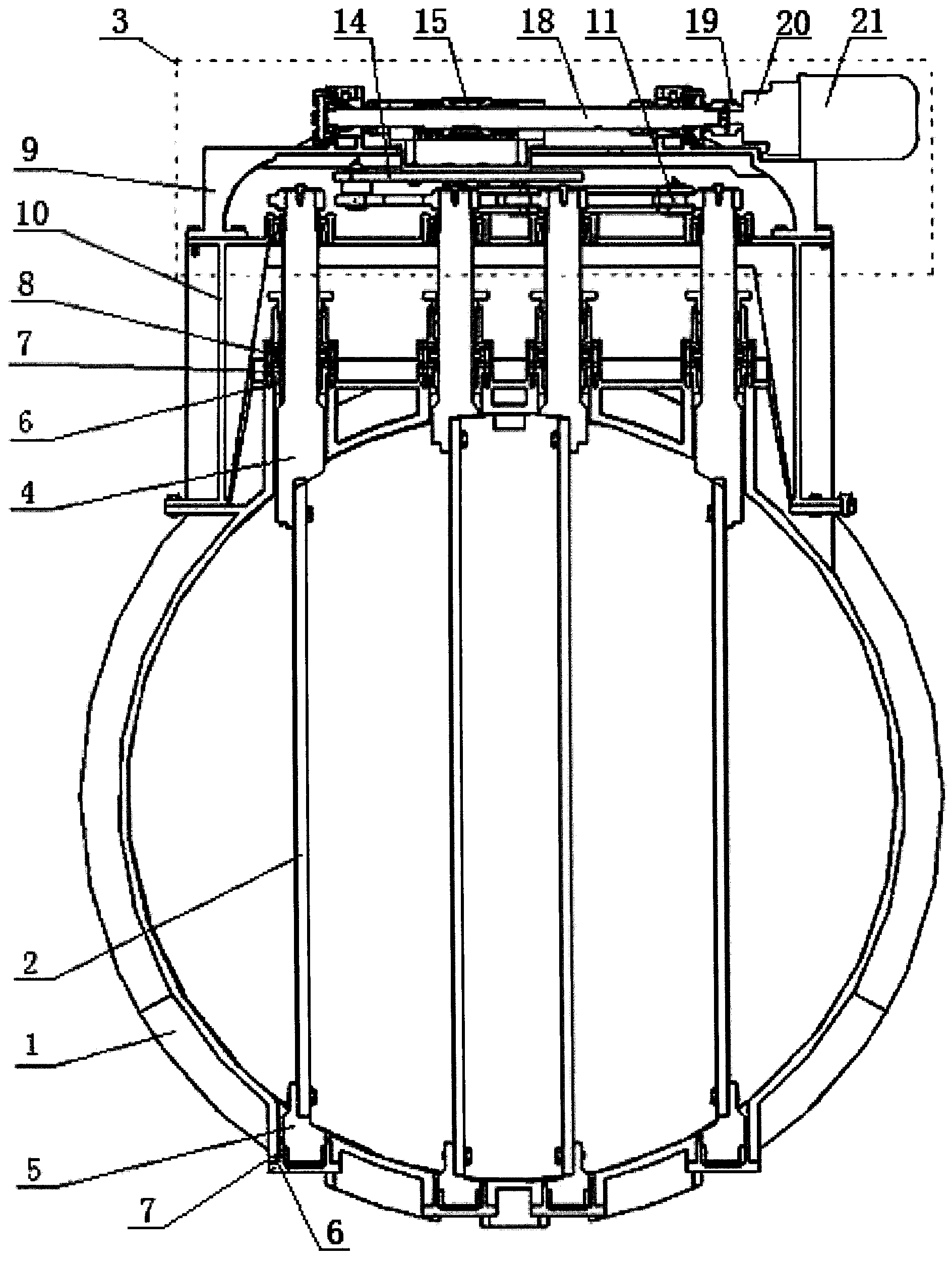

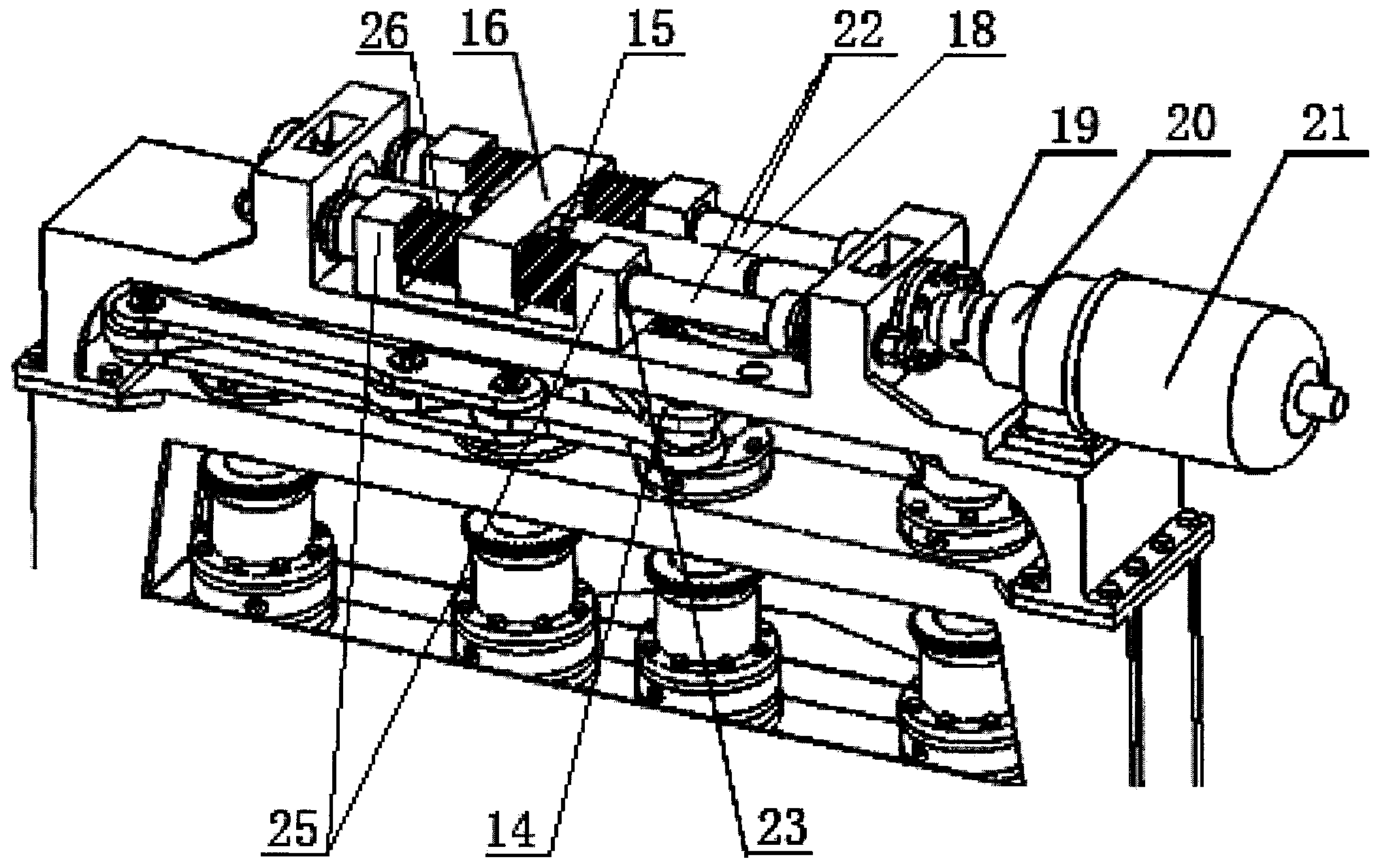

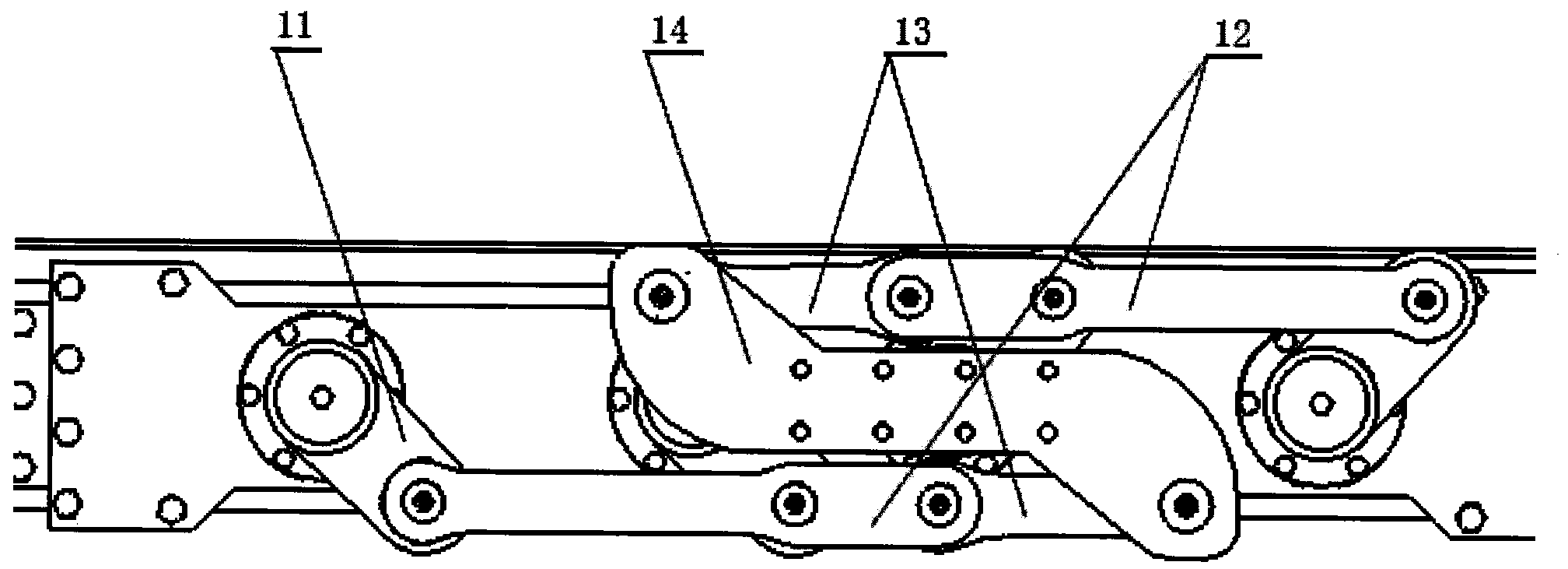

[0021] An embodiment of the present invention is: as Figure 1-Figure 4 A hull slot opening capping device is shown, the capping device is located at the exit of the slot opening, it includes a cylinder body 1, a cover plate 2, and a cover plate driving device 3, and the inside of the cylinder body 1 is as close as possible to the cylinder body 1 cylinder mouth There are 2 to 6 cover plates 2 symmetrically distributed along the center line of the circular section on the vertical circular section, which can realize 90° rotation. The rotation axes of the cover plates 2 are all parallel to the center line of the circular section. The vertical circular section of the cylinder; the two ends of the cover plate 2 are connected with the active rotating shaft 4 and the driven rotating shaft 5, and the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com