Converter steelmaking technology

A converter steelmaking and converter smelting technology, applied in the manufacture of converters, lime production, etc., can solve the problems of high TFe content, high smelting cost, and high CaO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

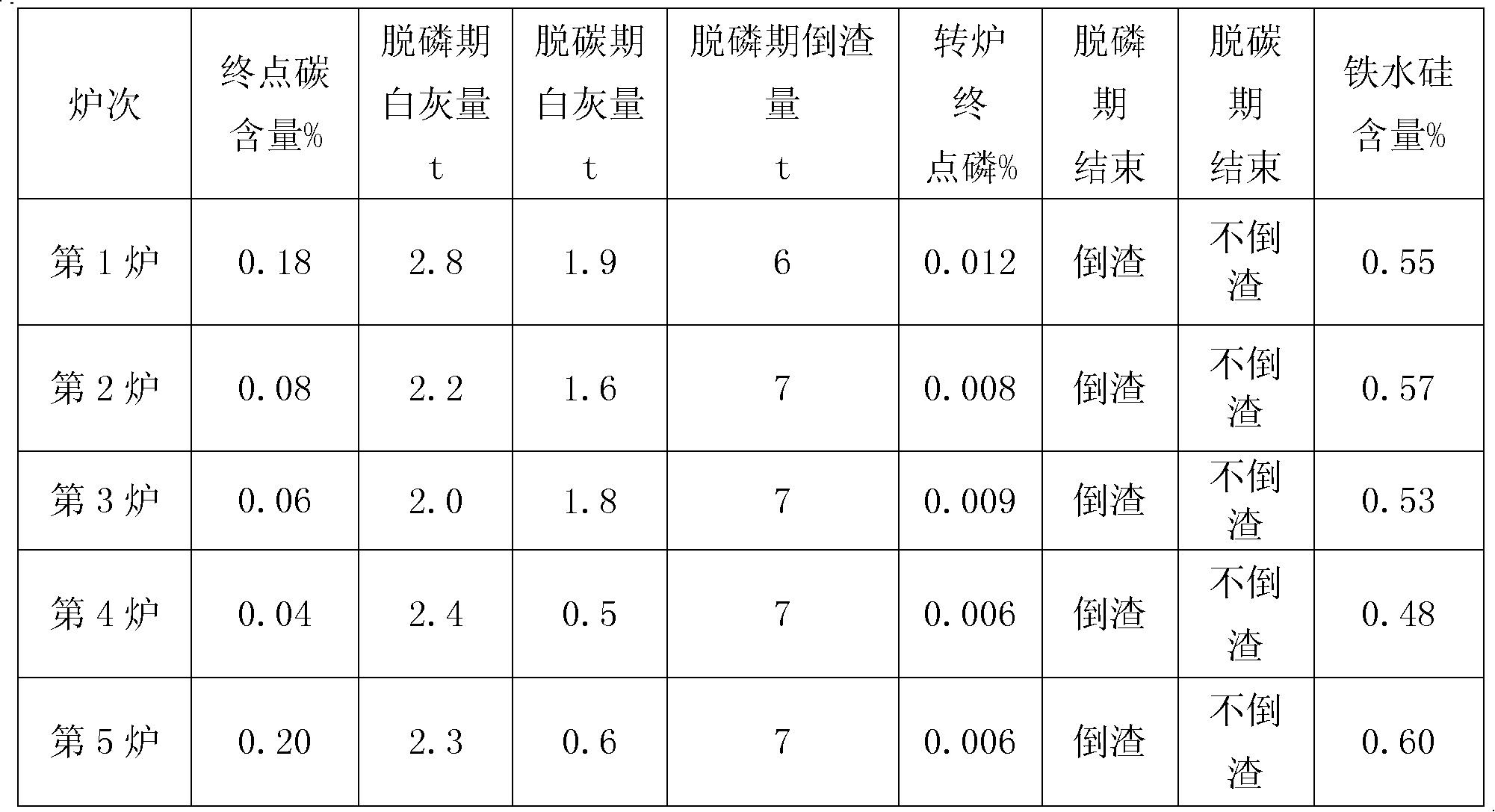

[0016] The smelting takes a 100-ton converter as an example. The smelting method is 5 consecutive furnaces. The blowing process is divided into a dephosphorization period and a decarburization period. About 65% of the total blowing time, slag dumping at the end of the dephosphorization period, the amount of slag dumping is shown in the table below, and no slag dumping at the end of the decarburization period. The amount of lime added gradually decreases with the increase of smelting cycle furnaces.

[0017] The smelting data are shown in the table below:

[0018]

[0019] As shown in the above table, the amount of lime added gradually decreases with the increase of continuous smelting heats, the phosphorus content at the end of the converter gradually decreases with the increase of circulating heats, and the slag is dumped at the end of the dephosphorization period, and the amount of slag dumped accounts for 1% of the total slag mass. / 3~1 / 2, no slag dumping at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com