Structurally waterproof flashing

A rainproof and waterproof technology, which is applied in the construction of buildings, roofs with flat/curved panels, roofs, etc., can solve problems such as inconvenient installation, easy aging of beading, and easy cracking of silica gel, so as to solve the problem of water leakage, Eliminates the effect of easy leakage and excellent waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

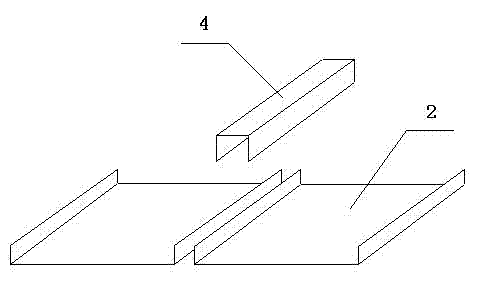

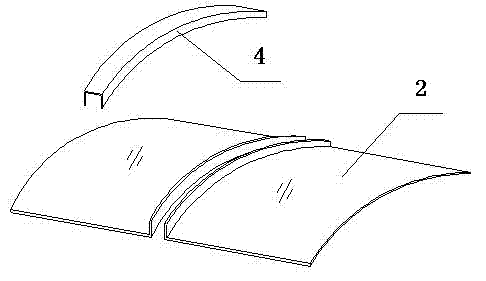

[0027] Such as Figure 7 As shown, the difference between the third embodiment of the present invention and the first embodiment is that the bracket arm 33 of the bracket 3 is perpendicular to the bracket shoulder 32, the fastener 4 is concave, and the two sides of the opening are respectively inward Bending to match the corresponding part of the bracket 3. The lower surface of the support shoulder 32 presses and fixes the daylighting panel 2 on the support frame 1 .

[0028] Such as Figure 8 As shown, the difference between the fourth embodiment of the present invention and the first embodiment is that there are margins 5 reserved on both sides of the opening of the fastener 4, such as Figure 9 As shown, the reserved edge 5 is bent to form a folded edge and occluded at the lower end of the bracket arm 33 of the bracket 3 , and the lower surface of the bracket shoulder 32 presses and fixes the daylighting panel 2 on the support frame 1 .

[0029] Such as Figure 10 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com