Three-slope metal roof ridge connection joint and installation method thereof

A technology for metal roofing and installation methods, applied to roofing, roof covering, and roofs using flat/curved panels, etc., can solve problems such as failure of sealing measures, roof leakage, economic losses, etc., to avoid breakage, good waterproof function, Good telescopic deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more perfectly disclosed, the following embodiments are provided hereby, and the following detailed descriptions are made in conjunction with the accompanying drawings:

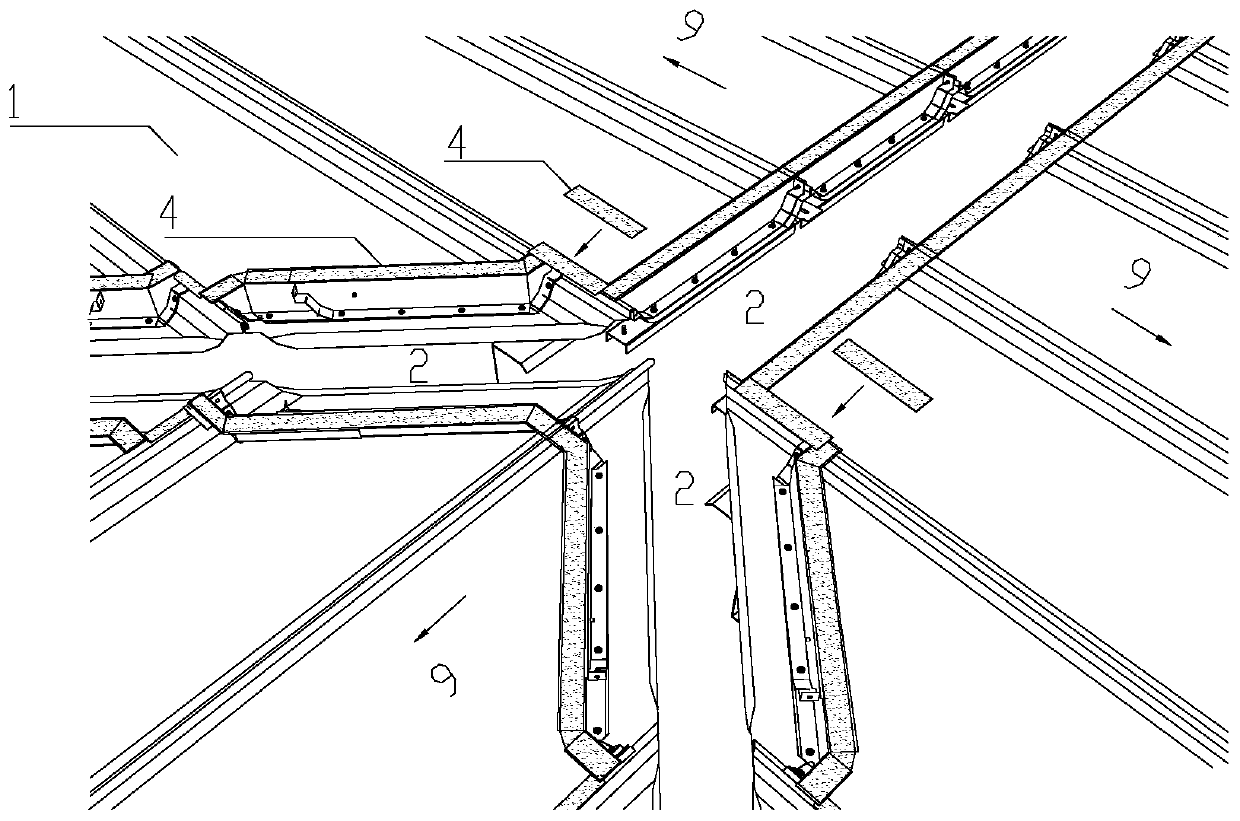

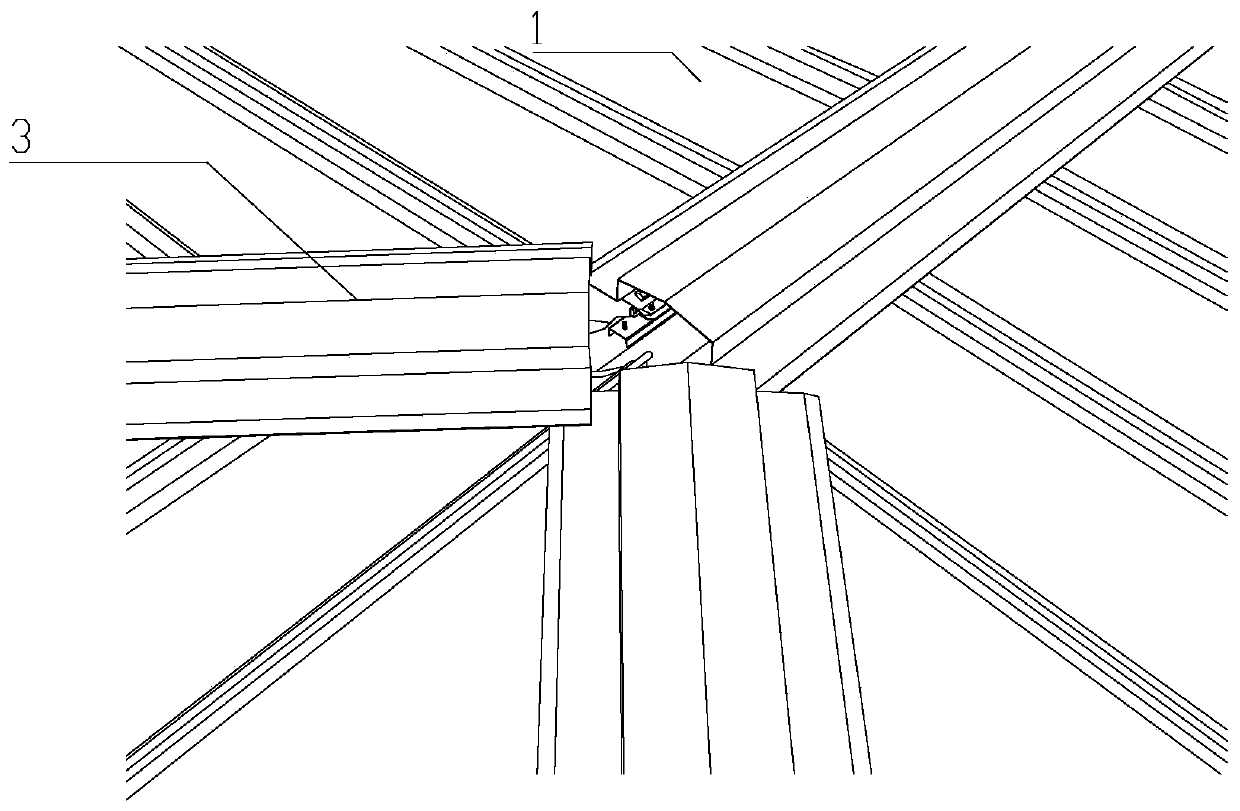

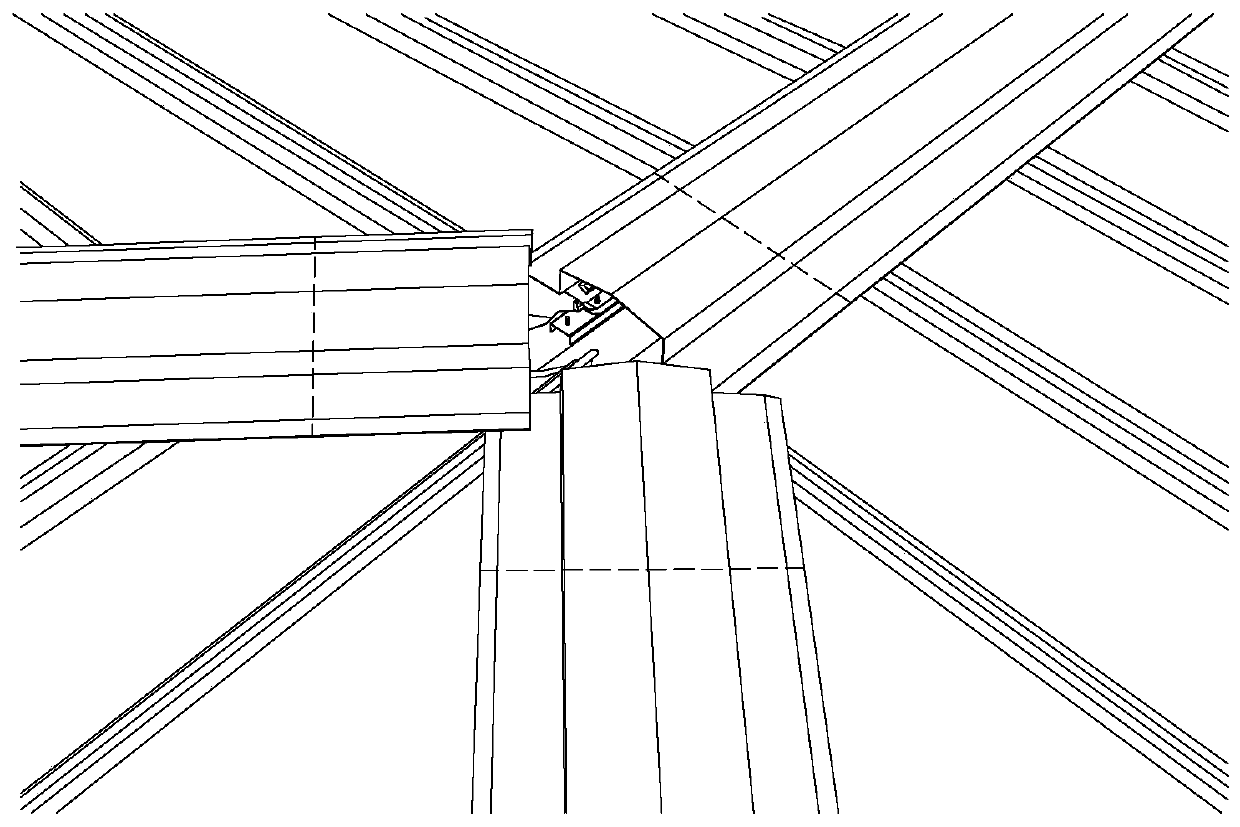

[0039] Such as Figure 1 to Figure 14 As shown, the ridge junction node of a three-slope metal roof in this embodiment includes three ridge junctions formed by three metal roof panels 1 with different slope directions. The three elastic ridge cover plates 3 at the ridge junction and the waterproof layer fixedly laid on the three elastic ridge cover plates 3 .

[0040] A first adhesive layer is laid between the elastic ridge cover plate 3 and the roof panel 1 , and a second adhesive layer is laid between the waterproof layer and the elastic ridge cover plate 3 . Continuous laying of the adhesive layer can better play a waterproof role.

[0041] Both the first glue layer and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com