Box culvert settlement joint construction method

A construction method and technology of settlement joints, applied in the field of settlement joints, can solve problems such as inability to ensure the accurate position and exposed length of dowel rods, inability to effectively ensure the smoothness of waterstops, and inability to effectively fix rubber waterstops, etc., to achieve favorable Overall stress, manpower saving, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A construction method for a box culvert settlement joint, comprising the following steps:

[0034] S1. Positioning and setting out: according to the centerline position of the steel edge waterstop on the construction drawings, the setting out is carried out;

[0035] S2. Template processing: process the plug template according to the size of the drawing, set the line on the plug template to determine the center position of the dowel, and then use a hand-held drill to drill holes on the plug template according to the diameter of the dowel;

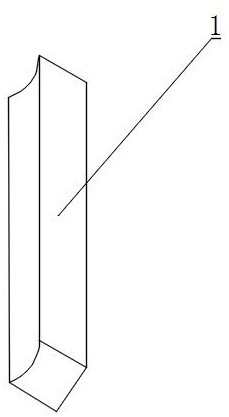

[0036] S3. Reinforcement installation of the steel edge waterstop: according to the center line setting position of the steel edge waterstop, a reinforced wooden square 1 is installed on both sides of the center of the steel edge waterstop, and the bottom of the reinforced wooden square 1 is provided with steel The groove that matches the convex groove at the middle part of the edge waterstop, the convex groove at the middle part of ...

Embodiment 2

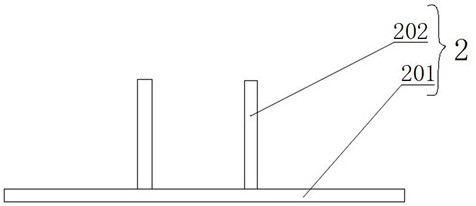

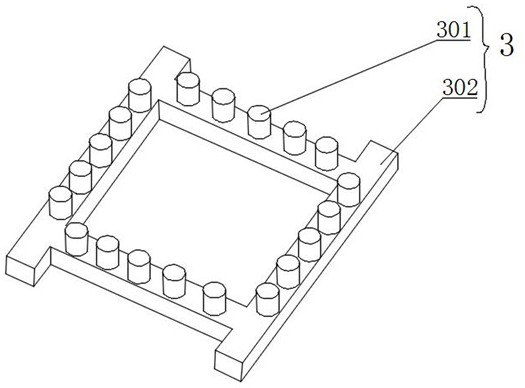

[0045] The difference with embodiment 1 is: in the S4 step, a steel bar support 2 is set at intervals of 40cm, the distance between two adjacent dowel bars is 40cm in the S5 step, and the diameter of the dowel bar is 30mm in the S6 step. The diameter of the cylinder 301 is 33mm, the length of the sleeve 301 is 20cm, when the vibrating rod vibrates in step S7, the distance between the vibrating rod, the steel edge waterstop and the dowel bar is 8cm, and the vibrating time is 60s.

Embodiment 3

[0047] The difference with embodiment 1 is: in the S4 step, a steel bar support 2 is set every 20cm apart, the distance between two adjacent dowel bars is 60cm in the S5 step, and the diameter of the dowel bar is 20mm in the S6 step. The diameter of the cylinder 301 is 23mm, the length of the sleeve 301 is 20cm, when the vibrating rod vibrates in step S7, the distance between the vibrating rod, the steel edge waterstop and the dowel bar is 12cm, and the vibrating time is 50s.

[0048] It can be seen from the above examples that when the steel edge waterstop is installed in the present invention, two pieces of reinforced wooden squares 1 are used in the middle part, and the lower part of the reinforced wooden square 1 is provided with a groove matching the middle part of the steel edge waterstop for clamping. Tight, it is helpful for the steel edge waterstop to be installed firmly. The horizontal part of the steel edge waterstop is fixed with a steel bar bracket 2 to ensure tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com