Method and device for leading pre-embedded pipes in concrete out of side wall joints

A technology of concrete interior and construction methods, which is applied to the processing of pipes and building materials, pipes/pipe joints/pipe fittings, etc., can solve problems such as damaged formwork, ensure construction quality and progress, improve construction efficiency, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

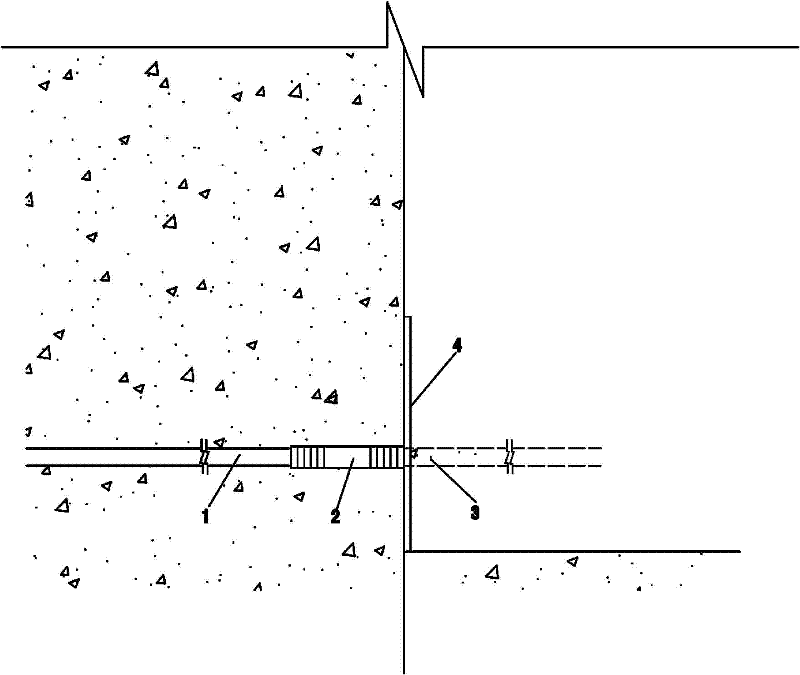

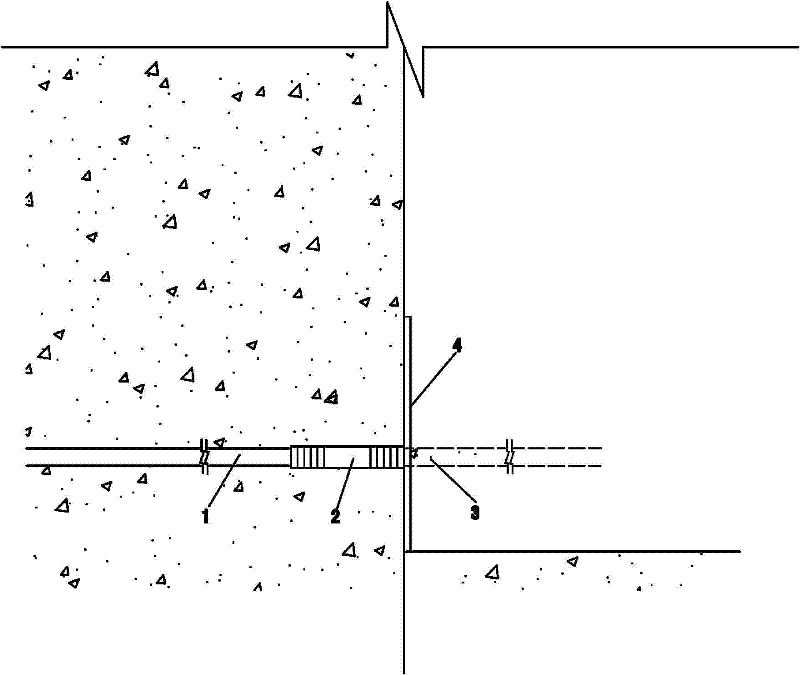

[0019] like figure 1 Among them, a construction method for the side wall joint where the concrete inner embedded pipe leads out includes the following steps:

[0020] A. According to the design drawings and construction planning, clearly mark the pipe number and group number, etc., locate the embedded pipe 1 in the concrete, lead the embedded pipe 1 to the designated position at the side wall joint, and process the thread on the pipe mouth, use The iron wire and the pipe clip fixedly connect the pre-embedded pipe 1 with the steel bar;

[0021] B. Bind steel bars according to the design requirements, set up side wall formwork; and fix it with steel pipe fences and braces.

[0022] C. One end of the casing 2 is threadedly connected to the embedded pipe 1, and the other end of the casing 2 is blocked and protected, and it is closely attached to the side wall formwork 4; specifically, the embedded pipe 1 at the joint needs to be led out To the side wall, a casing 2 with a diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com