Cutter of comprehensive mechanized rock tunnel boring machine

A comprehensive mechanization and roadheader technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as slow progress in rock roadway excavation, and can not solve the problems of complex technology, so as to achieve stable and reliable work, compact structure, and improved development Ergonomic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Carry out the specific embodiment of the present invention in detail below in conjunction with accompanying drawing:

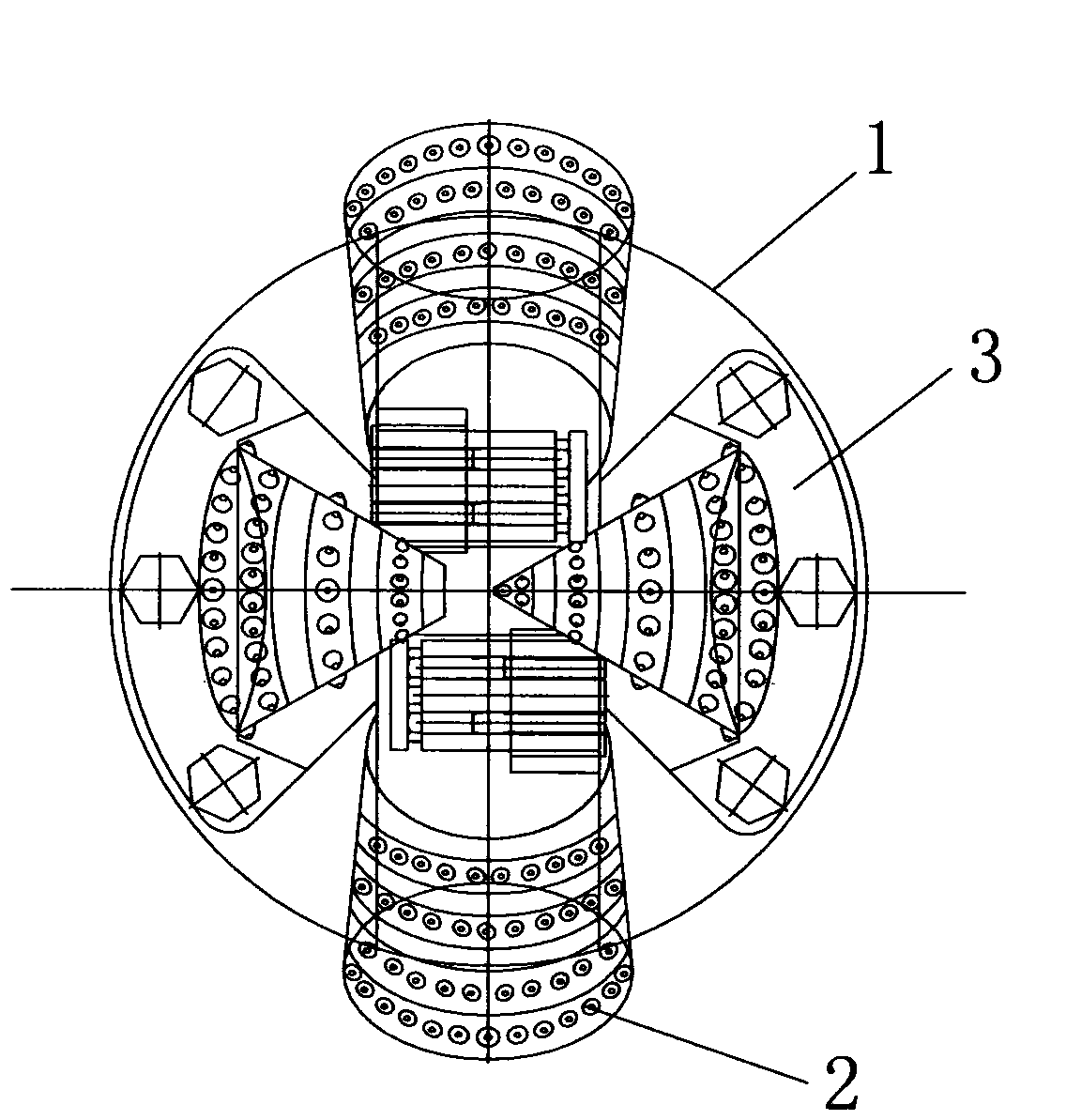

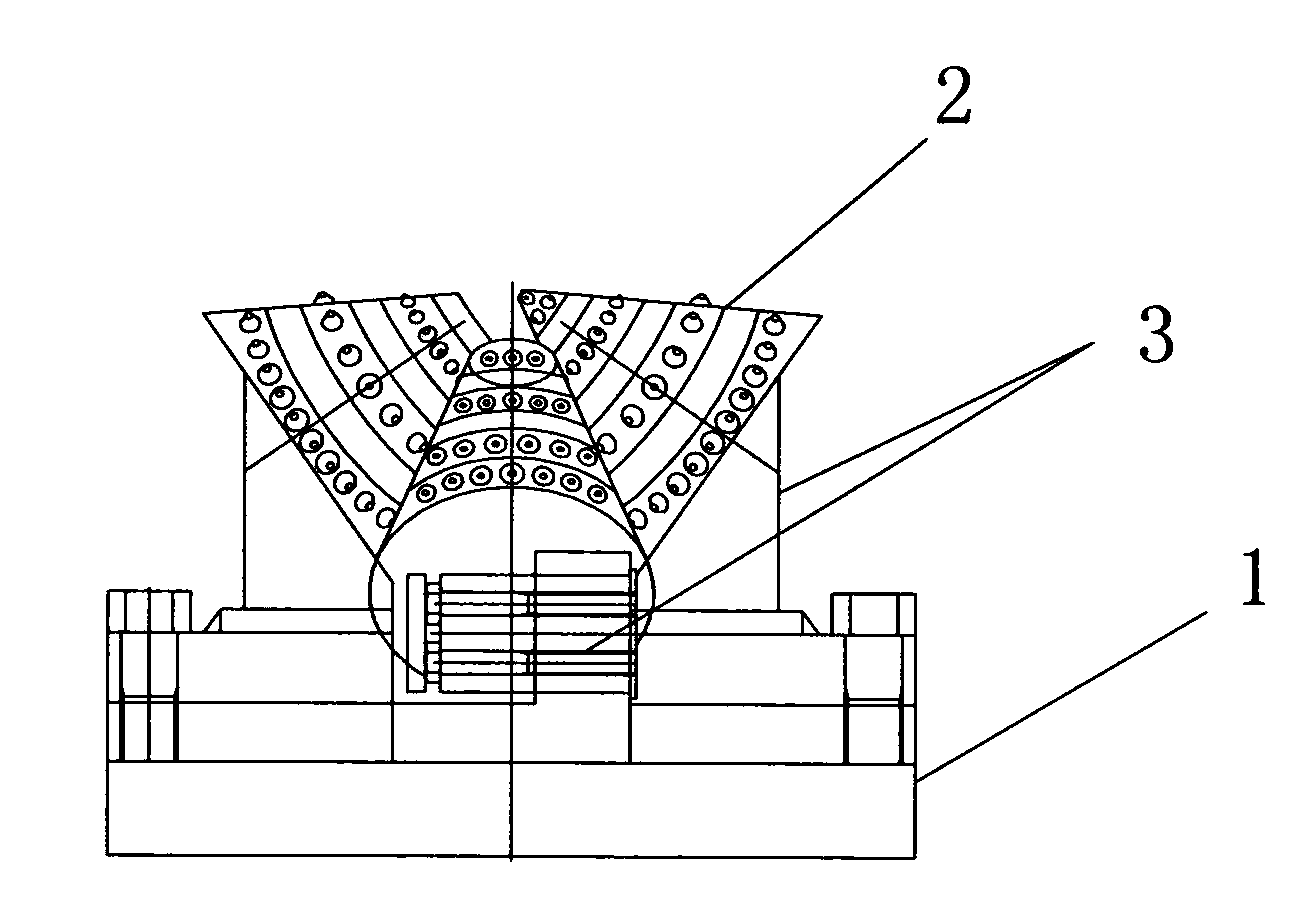

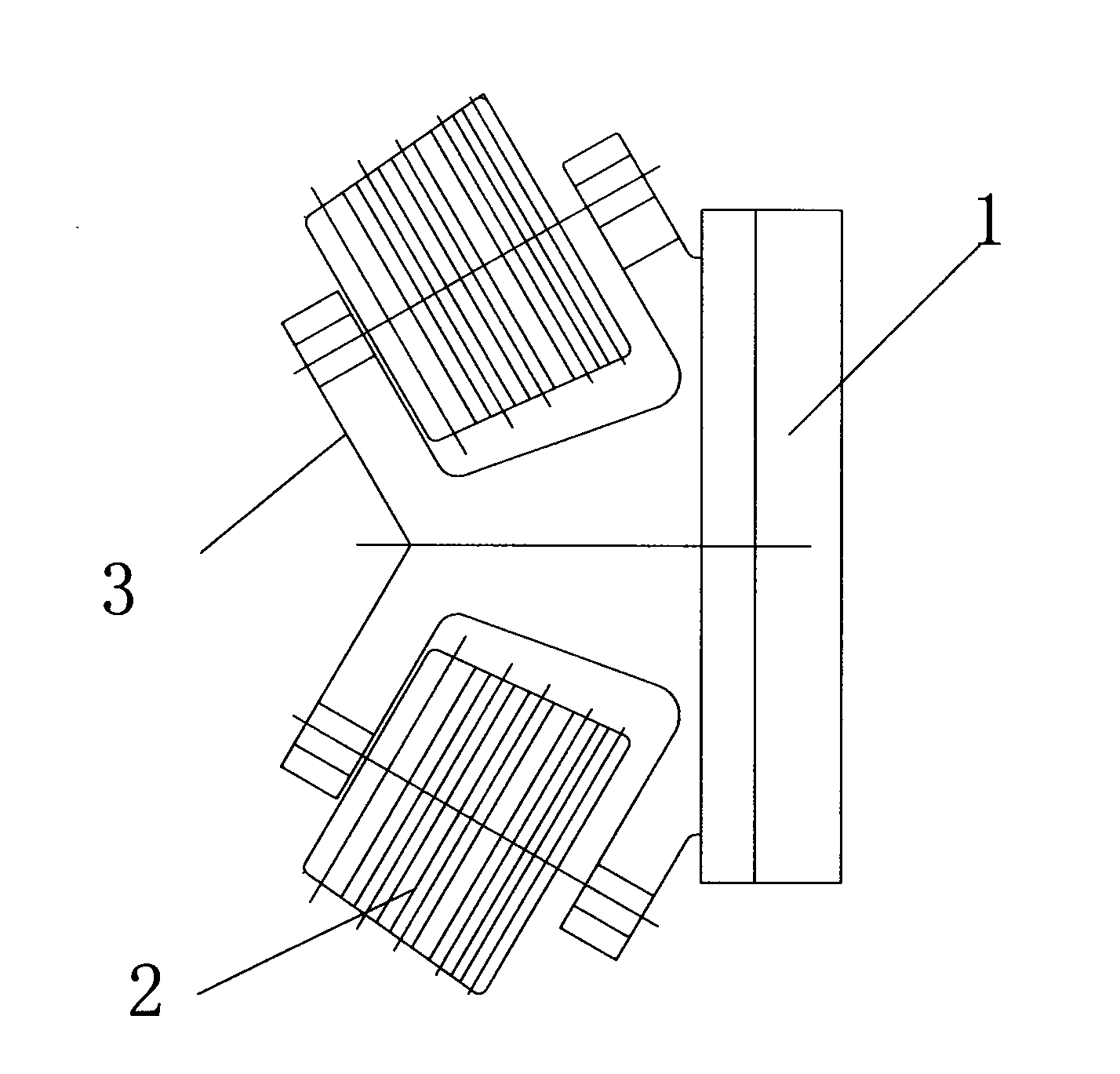

[0014] Such as figure 1 and figure 2 Shown, the cutter of the integrated mechanized roadheader. It includes a cutterhead 1, a tapered hob, a tapered hob shaft and a hob bearing 2, and a hob shaft seat 3; The hob bearing and the hob shaft are installed in the hob shaft seat.

[0015] There are four conical hobs of the cutting tool, among which: among the four conical hobs, there is a single hob axel seat conical hob, there is a single hob axel seat conical hob, and Two double hob pedestal conical hobs; said single hob pedestal conical hob mounted on the first cutting surface; single hob pedestal conical hob on the second cutting surface ; Two double-cutter pedestal conical hobs are installed on the third or fourth cutting surface respectively, and the single hob pedestal conical hob and the single hob pedestal conical hob The knives are arranged sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com