Excavation and retaining wall construction technology of super-large cross-section inclined single-pile foundation

A super-large cross-section, single-pile foundation technology, applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of inability to monitor the changes of surrounding rocks in real time, the difficulty of inclined shaft construction, and the mechanical coordination of narrow space, etc., to achieve The effect of improving the level of mechanized construction, high practical value, and simple excavation process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

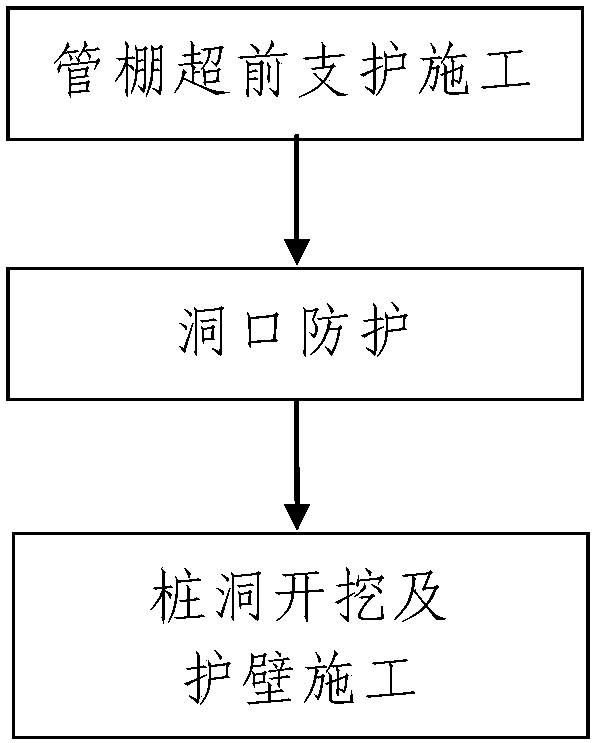

[0055] Such as figure 1 The excavation and retaining wall construction technology of a super-large cross-section inclined single-pile foundation is shown. The super-large cross-section inclined single-pile foundation is a reinforced concrete pile, and the cross-sectional area of the reinforced concrete pile is greater than 100m 2 And its inclination angle is greater than 45°; when excavating and constructing the retaining wall of the super-large cross-section inclined single pile foundation, the following steps are included:

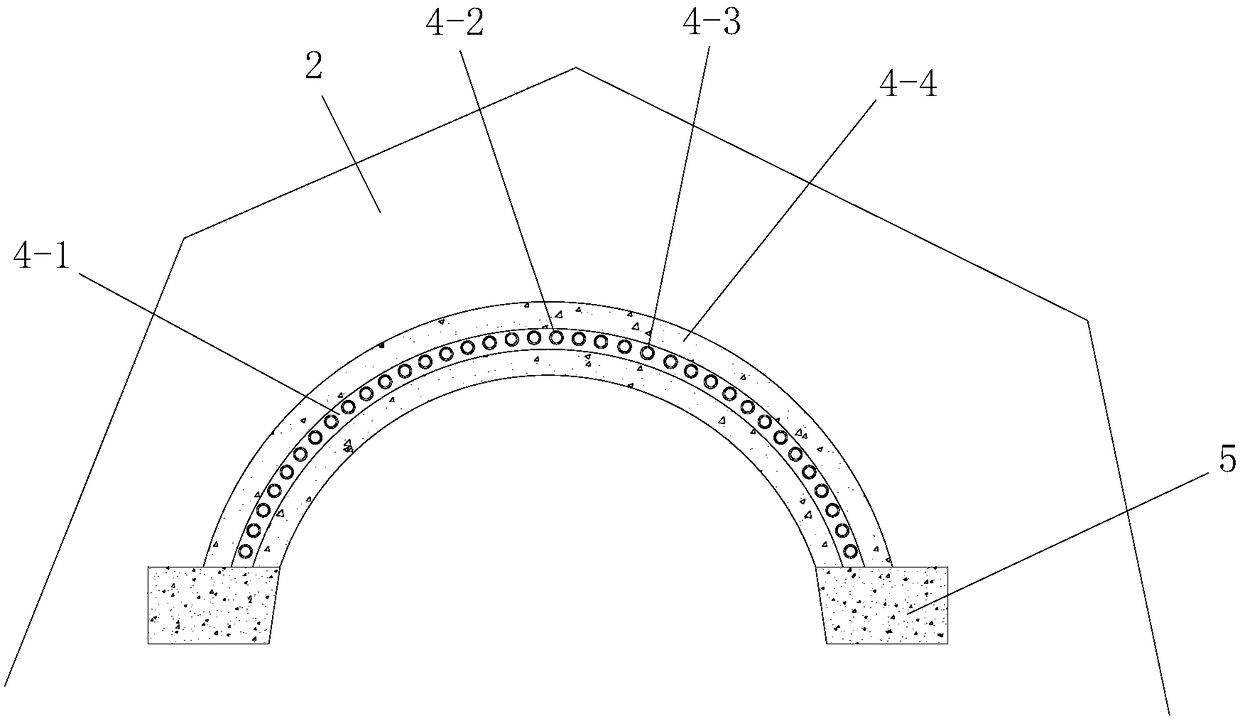

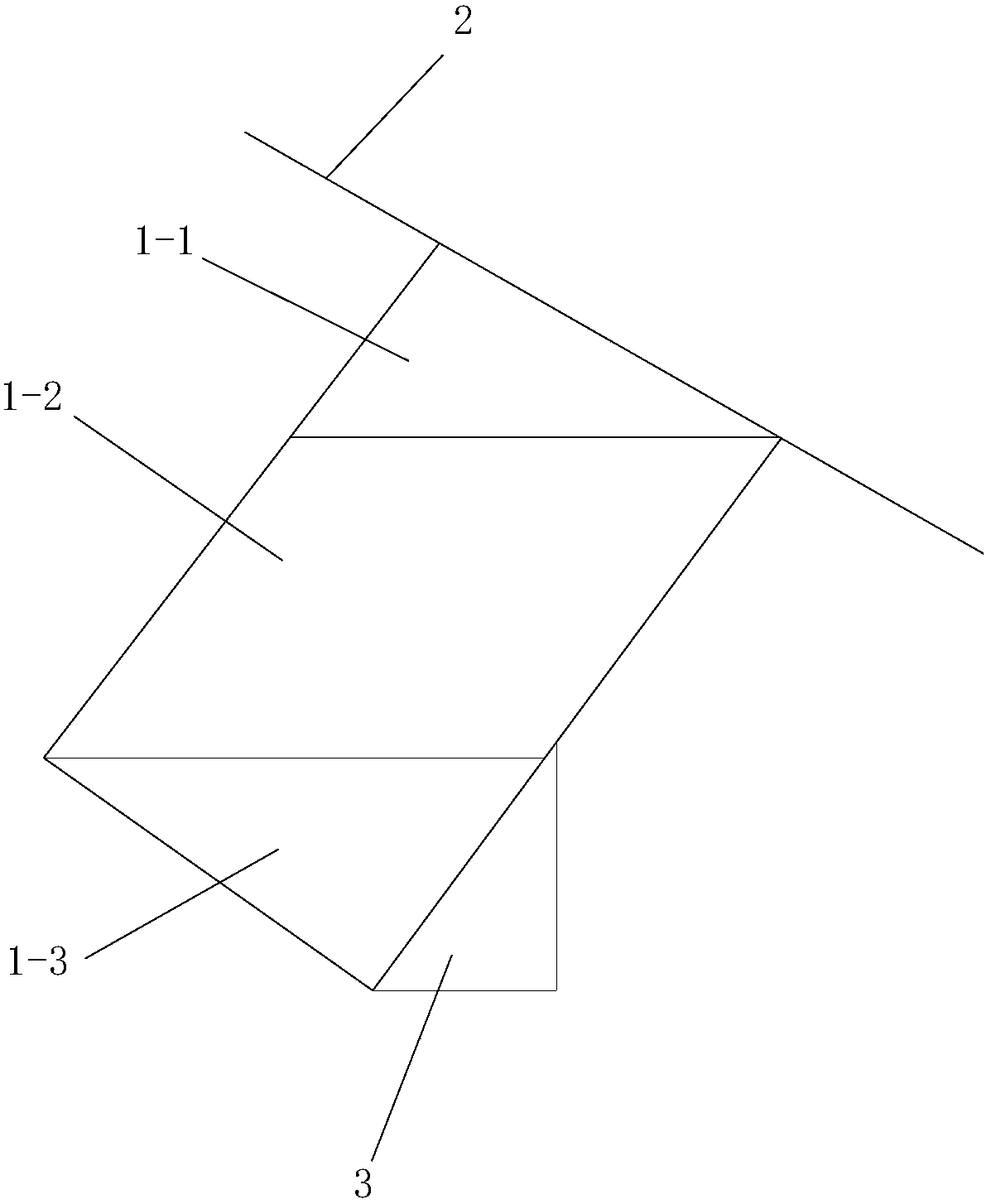

[0056] Step 1. Advance support construction of pipe shed: Before excavating the pile hole 1 of the super-large cross-section inclined single pile foundation, the pipe shed advance support construction is carried out on the top of the pile hole 1 to obtain the formed pipe shed advance support structure, see figure 2 ;

[0057] Step 2, opening protection: construction of opening supporting structure at the opening of pile hole 1;

[0058] Step 3. Exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com