Pipeline centrifugal pump for ship

A pipeline type, centrifugal pump technology, applied in non-variable pumps, pumps, components of pumping devices for elastic fluids, etc., can solve the problems of cabin space occupation, safety hazards, combustion, etc., to avoid accidents , save the use of space, avoid burning and explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

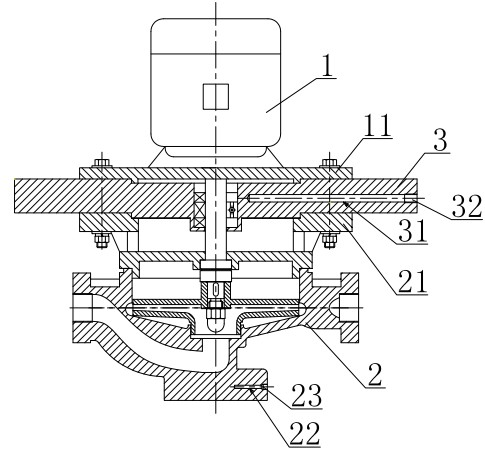

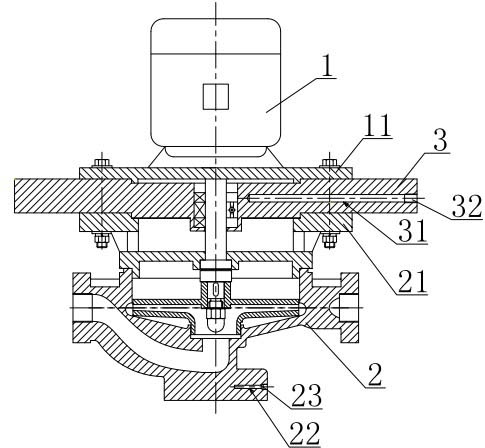

[0007] like figure 1 As shown, the marine pipeline centrifugal pump includes: a motor 1 and a pump body 2, wherein the bottom of the motor 1 is provided with a connecting plate 11, and the upper end of the pump body 2 is provided with a motor seat 21, and the motor seat 21 and the connecting plate 11 are provided There is a round flange 3, and the motor base 21 and the connecting plate 11 are connected to the round flange 3 by bolts. One side of the round flange 3 is provided with a first temperature measuring hole 31, and the first temperature measuring The hole 31 is provided with a first temperature sensor 32 connected to a temperature monitoring device; the pump body 2 is also provided with a second temperature measuring hole 22, and the second temperature measuring hole 22 is also provided with a second temperature sensor connected to a temperature monitoring device. The position of the temperature sensor 23 and the second temperature measuring hole 22 can generally be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com