Self-aligning hydraulic clutch release bearing

A hydraulic clutch and release bearing technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of large clutch separation force, strength, and sealing performance that cannot meet the requirements of use, and achieves convenient gear shifting and weight. Light, smooth separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

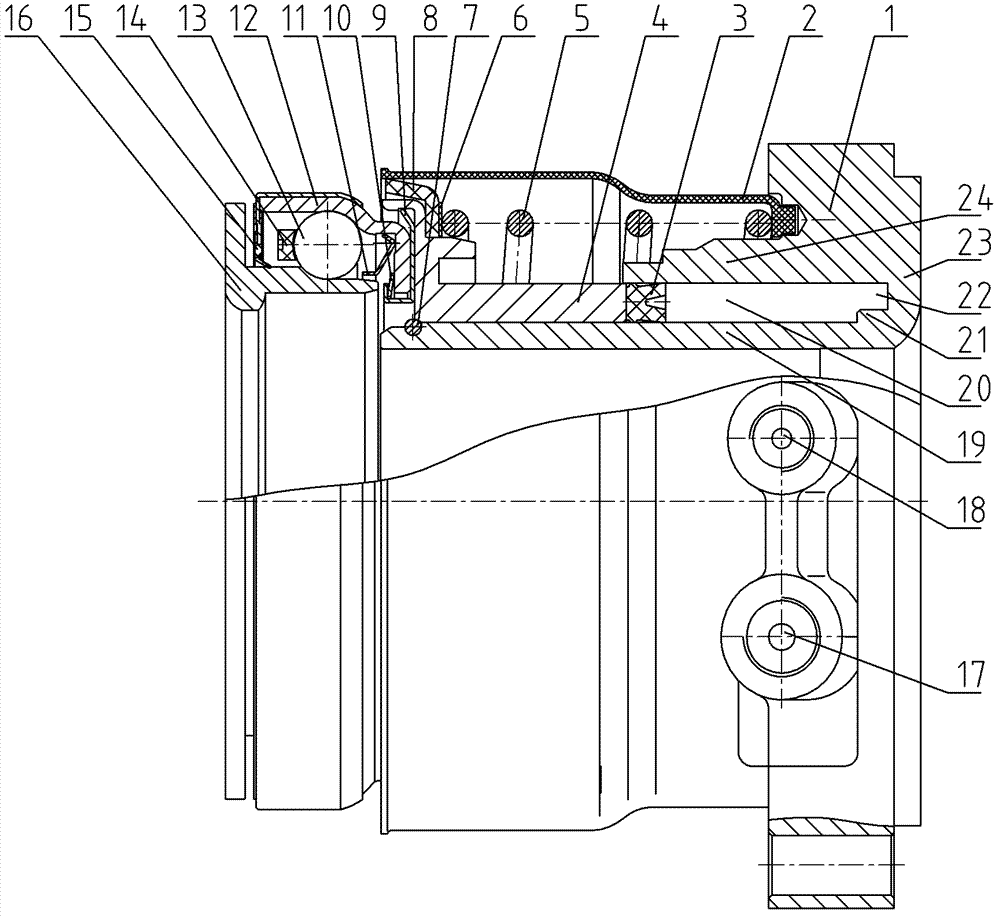

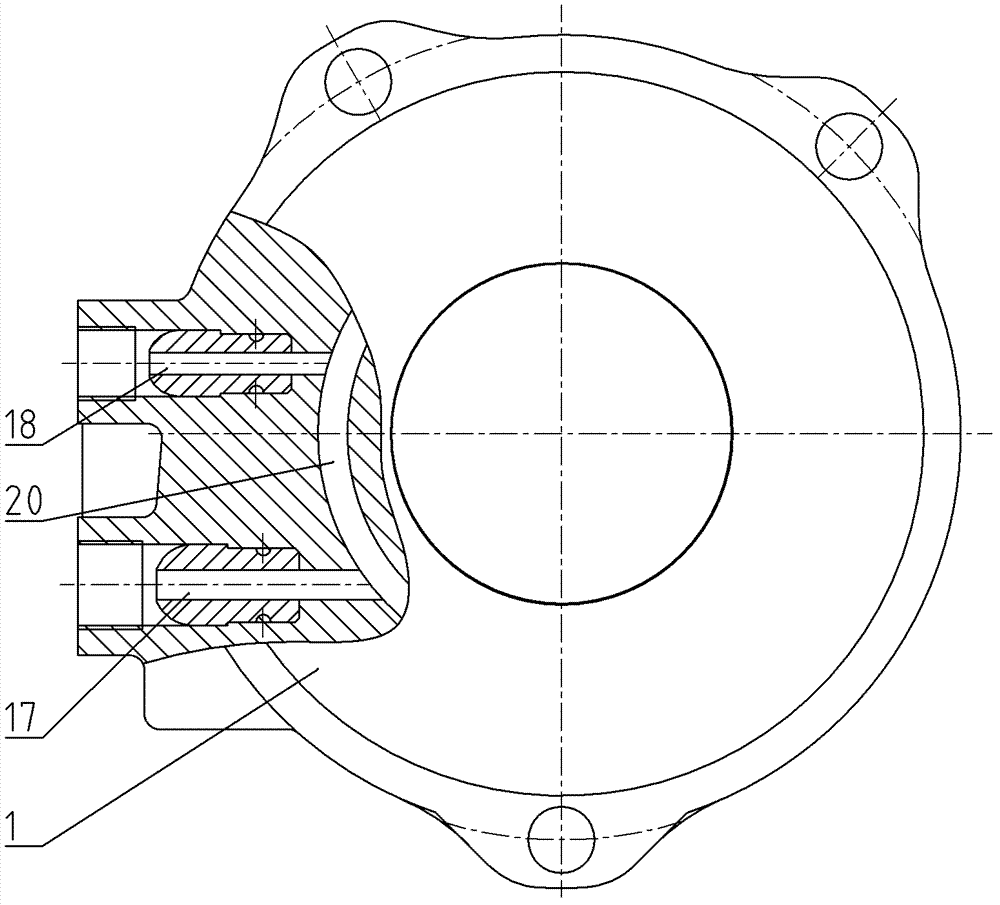

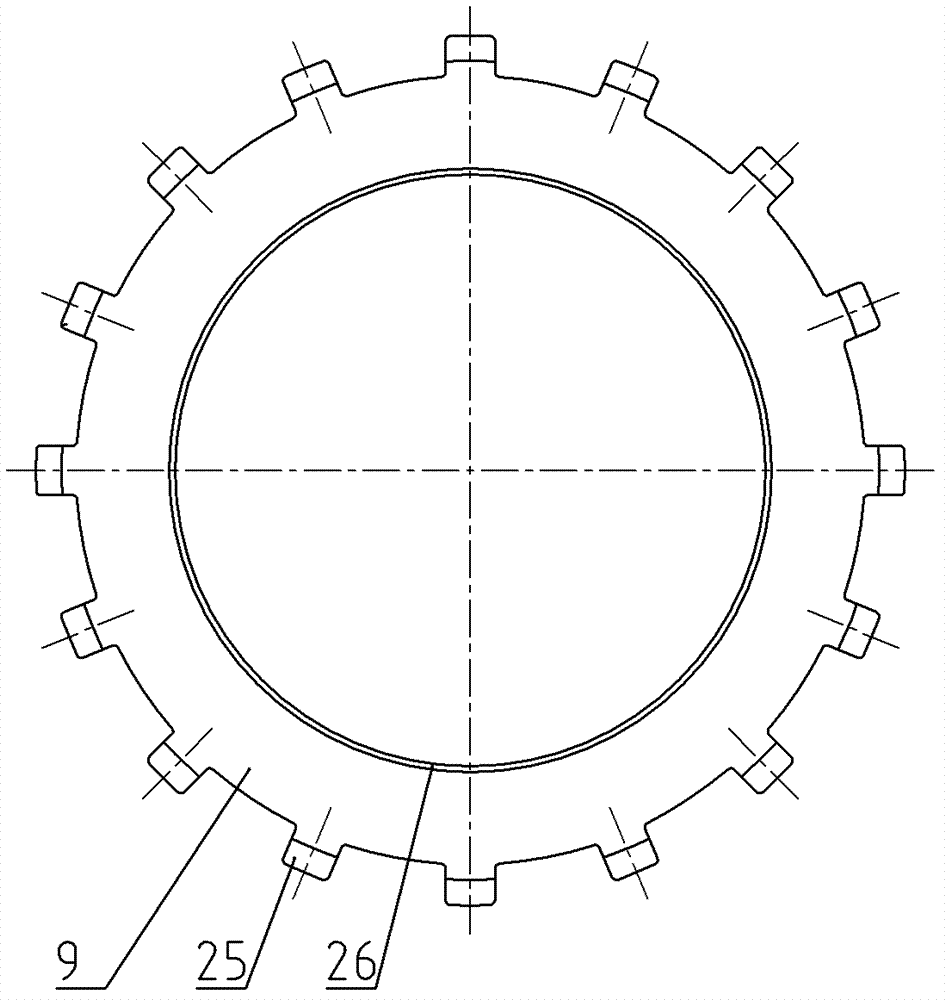

[0014] Figure 1~Figure 4 Including hydraulic cylinder block 1, dust cover 2, hydraulic sealing ring 3, sliding sleeve 4, preload spring 5, support pad 6, circlip 7, rubber dustproof sealing ring 8, toothed connecting piece 9, disc Shaped reed 10, dust cover 11, bearing outer ring 12, ball 13, cage 14, rubber sealing cover 15, bearing inner ring 16, oil inlet channel 17, exhaust channel 18, cylinder inner tube 19, oil chamber 20. Shaft shoulder 21, groove 22, cylinder body 23, cylinder outer cylinder 24, teeth 25, shaft cylinder 26, etc.

[0015] Such as figure 1 , figure 2 As shown, the present invention is a self-aligning hydraulic clutch release bearing, including a hydraulic part and a release bearing part.

[0016] The hydraulic part includes a hydraulic cylinder block 1, a sliding sleeve 4 and a preload spring 5. The hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com