Flexible metal tube static bending test machine

A static bending and metal hose technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of no special testing machine, no static bending inspection method, no specified static bending inspection items, etc., to achieve convenience Effects of mounting, reducing damage, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

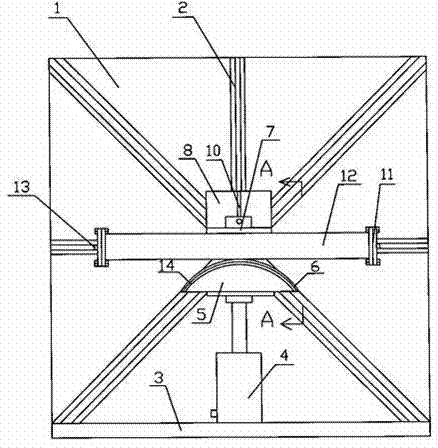

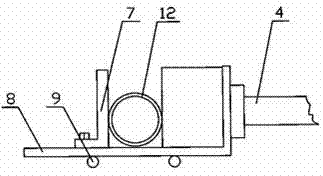

[0022] Such as Figure 1~2 As shown, the main structure of the present invention includes a platform 1, a linear oil cylinder 4 and a pumping station. The support plate 3, the groove parallel to the fixed support plate in the "m"-shaped groove is connected with the general tooling 11 at both ends of the test piece through the transverse movement mechanism 13, and the " L"-shaped supporting plate 8, a solid body 5 with a round crown in cross-section is arranged between the vertical plate of the "L"-shaped supporting plate and the test piece. The body is provided with a front baffle 7 that is limited by a position fixing groove 10 on the "L"-shaped horizontal plate on the other side of the test piece, and the lower side of the "L"-shaped horizontal plate is also connected to the horizontal plate by an axial movement mechanism 9. The groove connection of the vertical support plate in the "m"-shaped groove is connected with the linear oil cylinder 4 connected with the pumping sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com