System and method for monitoring energy efficiency of economical coal-fired boiler

A coal-fired boiler and monitoring system technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of boilers that cannot optimize boiler operating parameters, boiler operating efficiency, boiler adjustment, and poor timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

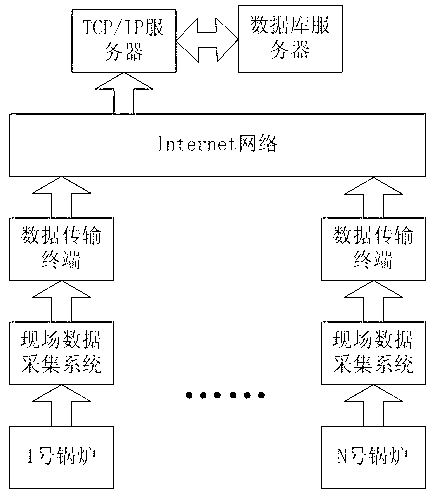

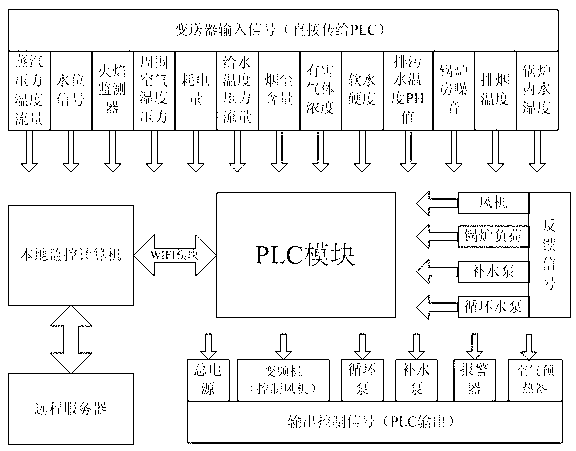

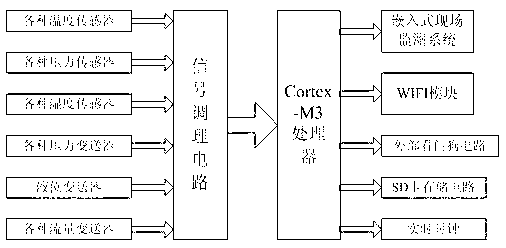

[0031] The system consists of three aspects: on-site data acquisition system, on-site monitoring system and remote supervision and service system. The real-time data of boiler operation is collected through the on-site data acquisition system, and the data terminal at the boiler operation site transmits the data to the remote monitoring system through the Internet. The remote monitoring system realizes the safe access, storage, statistics and analysis of the real-time data of the online boiler. , compare, identify, and publish. Considering that the objects of this system are various boilers that are widely distributed in space, this system adopts B / S (browser / server) architecture in structure to ensure that users can get real-time information at any time and any place through the Internet. Changes in boiler operation. The on-site monitoring syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com