Heat dissipation type bus duct

A busway and heat dissipation technology, applied in the field of busway, can solve the problems of busway burning, electrical equipment damage, economic loss, etc., and achieve the effect of improving product performance and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

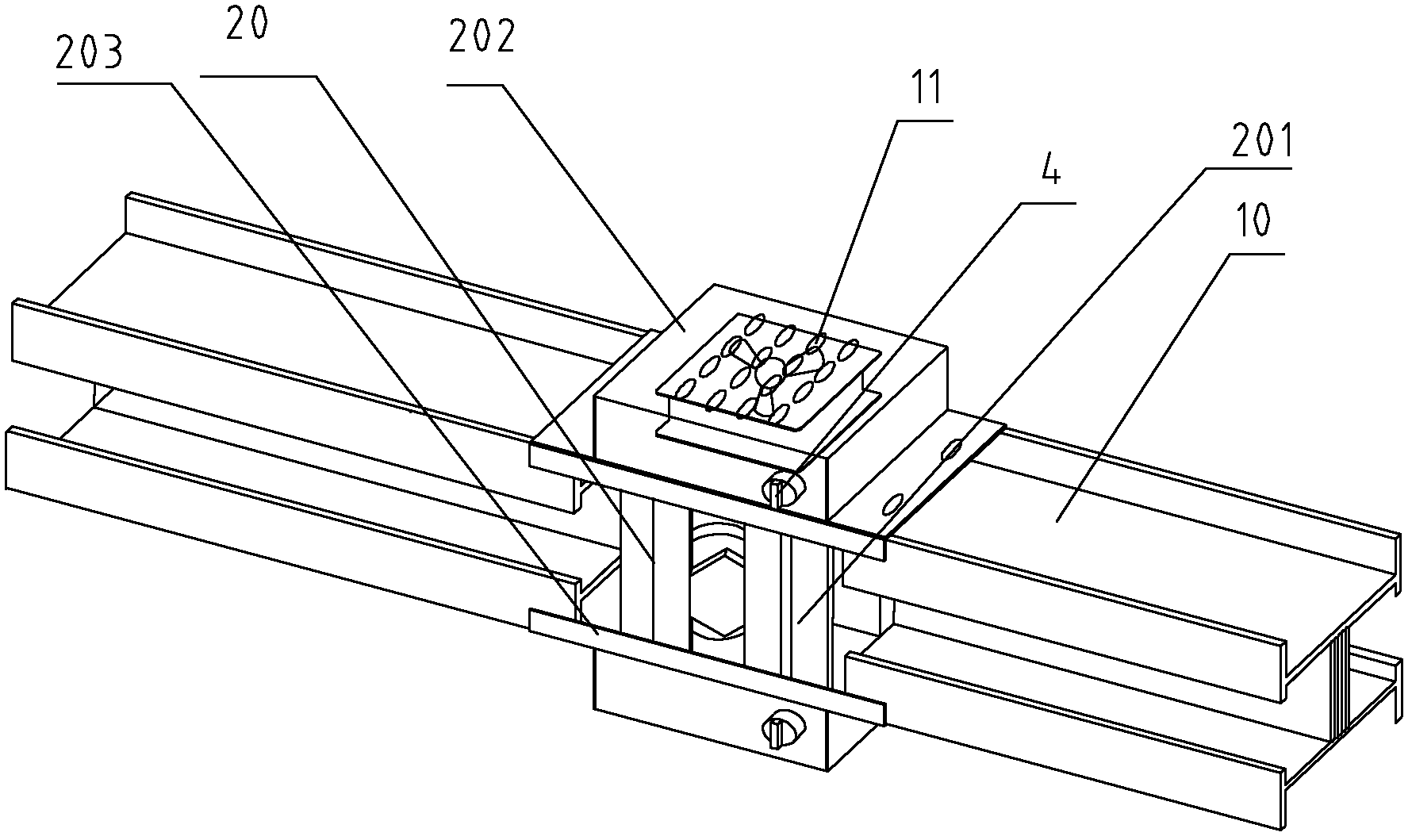

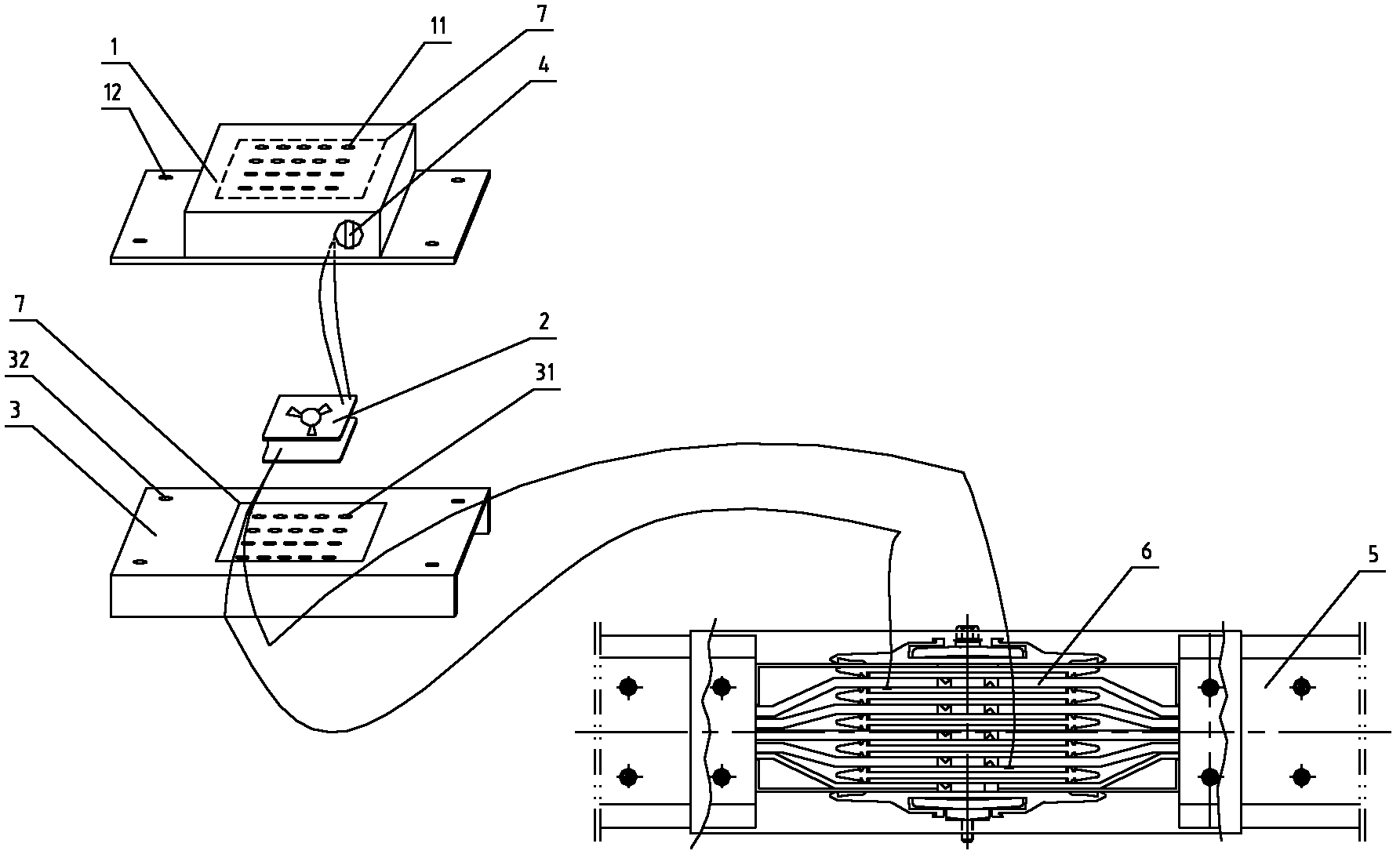

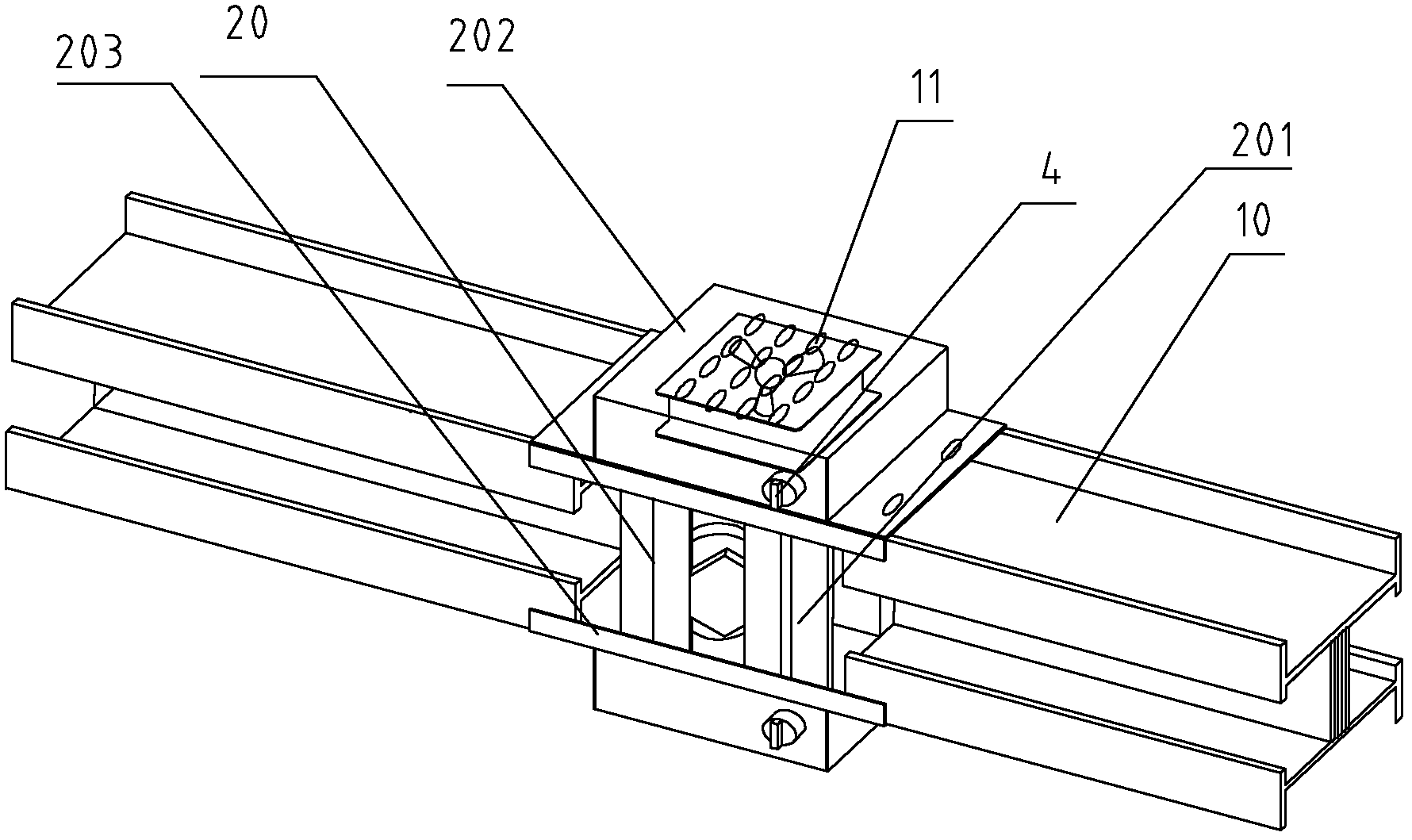

[0013] As shown in the figure, a heat-dissipating busway includes at least two busbar bodies 10, and the adjacent busbar bodies are connected into one body through a connecting device. The connecting device includes a connecting seat 20, and the two ends of the connecting seat 20 are respectively Connected to one end of the corresponding bus bar body 10, the connecting seat 20 includes a column 201, an upper connecting plate 202, and a lower connecting plate 203, and the upper connecting plate 202 has a cross section of The lower connection plate 203 is a groove-shaped member; the upper and lower ends of the column 201 are vertically connected with the upper and lower connection plates 202, 203 respectively, and the column 201 is connected with the upper and lower connection plates 202, 203 presented The upper and lower connecting plates 202, 203 and the side plates of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com