Device for assembling stator and rotor of motor

An assembly device, stator and rotor technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of reducing production efficiency and production quality, assembly difficulties, and affecting production progress, so as to improve production efficiency and production quality, facilitate assembly, and assemble easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

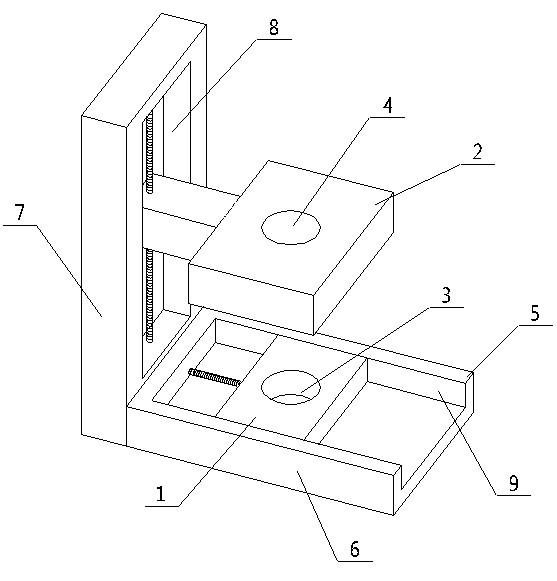

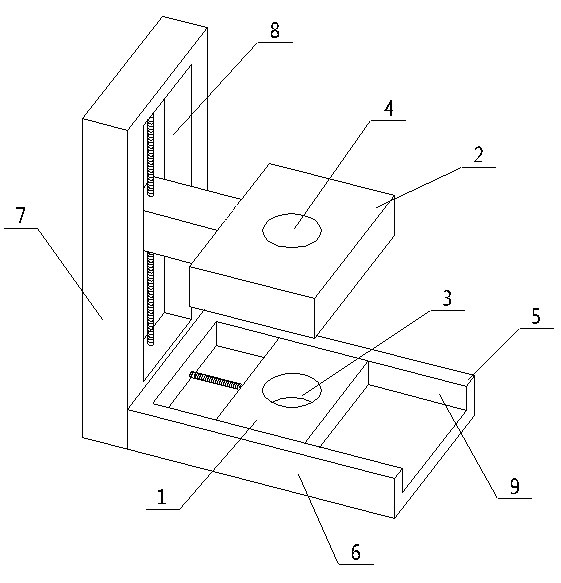

[0013] as attached figure 1 Shown is a motor stator and rotor assembly device according to the present invention, including a sliding plate 1, a lifting platform 2 and a base 5; the sliding plate 1 and the lifting platform 2 are arranged parallel to each other; the sliding plate 1 is fixed, and the lifting platform 2 Move in the direction perpendicular to the sliding plate 1, away from or close to the sliding plate 1; the sliding plate 1 has a mounting hole 3. The lifting platform 2 is provided with a mounting hole b4, and the center line of the mounting hole b4 coincides with the center line of the mounting hole a3; the base 5 is formed by connecting and fixing the horizontal support 6 and the vertical support 7 head to tail , and the horizontal support 6 is located at the bottom of the vertical support 7; the sliding plate 1 is horizontally fixed on the horizontal support 6; the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com