Stepping motor controller and image-reading device

A technology for stepping motors and controllers, applied in motor generator control, printing devices, control systems, etc., can solve problems such as inability to restore drive stepping motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

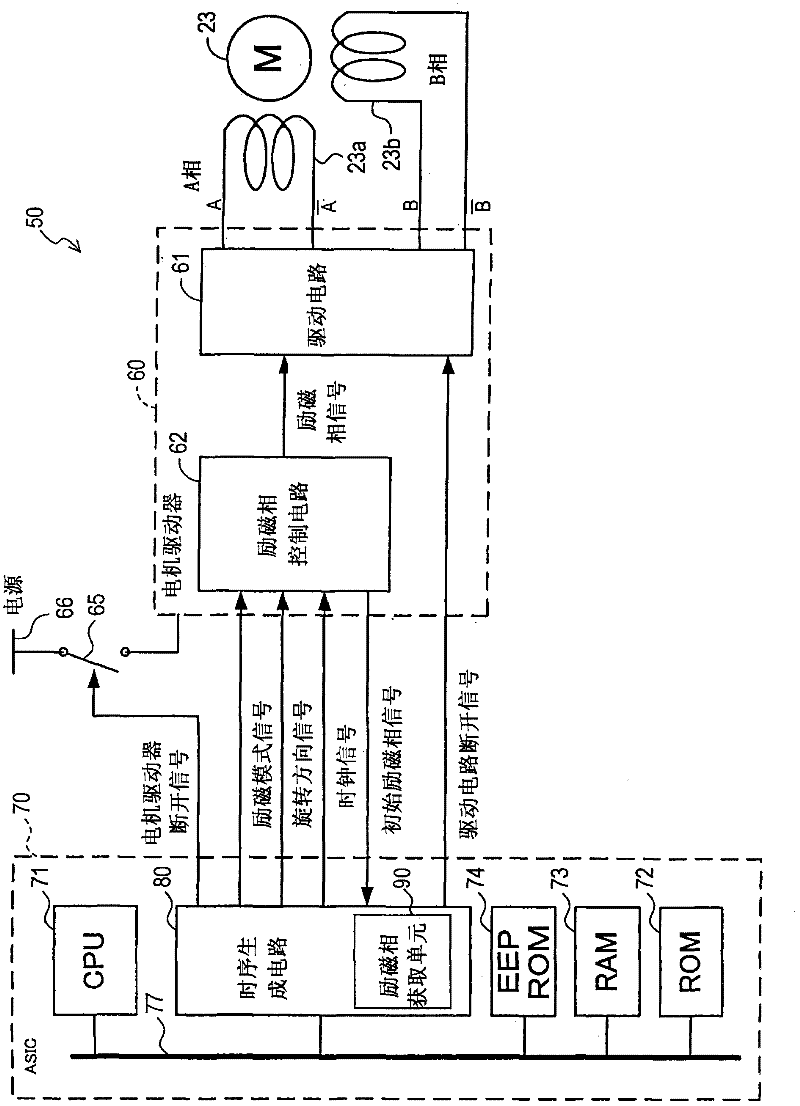

[0031] The structure of the stepper motor controller

[0032] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a block diagram showing the structure of a stepping motor controller (hereinafter simply referred to as "motor controller") 50 according to an embodiment of the present invention. Such as figure 1 As shown in , the motor controller 50 is composed of a motor driver 60 having a switch 65 and an application specific integrated circuit (ASIC) 70 that controls the motor driver 60 described below. The motor controller 50 is used to control the stepping motor (hereinafter referred to as “motor”) 23 .

[0033] The ASIC 70 is not only used to control the motor driver 60 . For example, when the motor 23 is integrated into the following image reading device 1 (see Figure 4 ) and the motor controller 50 controls the motor 23, the ASIC 70 may be configured to control the reading unit 21 described below and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com