Walking stool for agricultural machinery

A stool and agricultural machinery technology, applied in the field of stools, can solve the problems of high production cost, unfavorable popularization and application, unfavorable cultivation of small fields in southern hilly areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

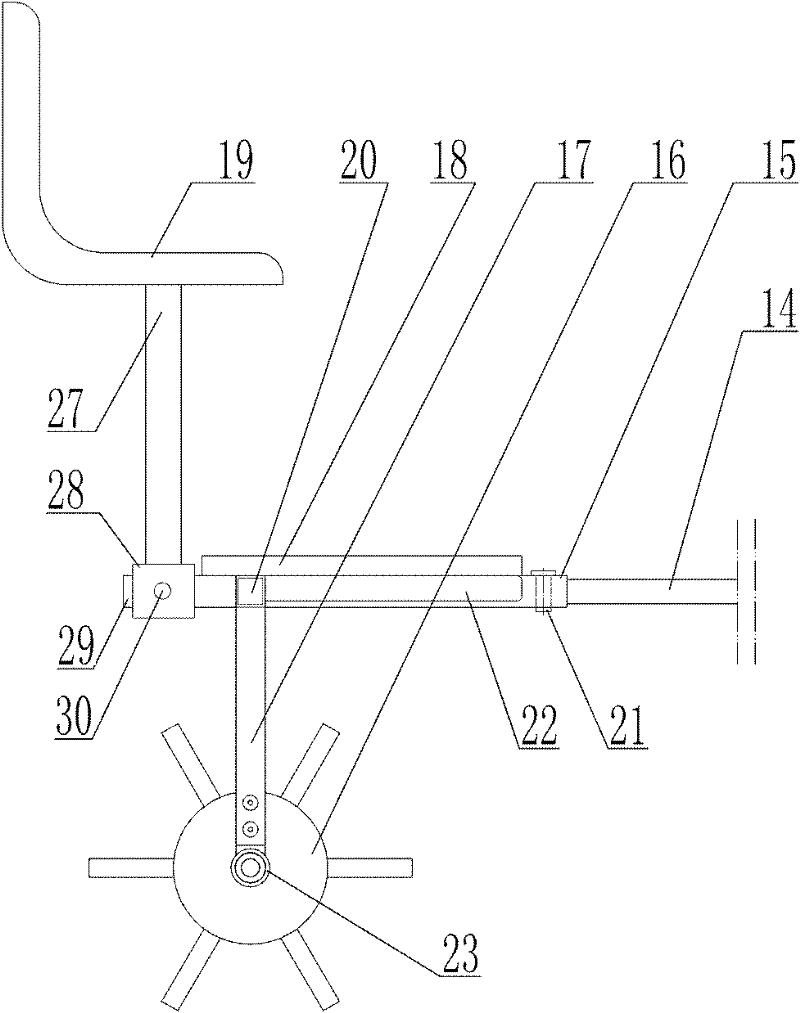

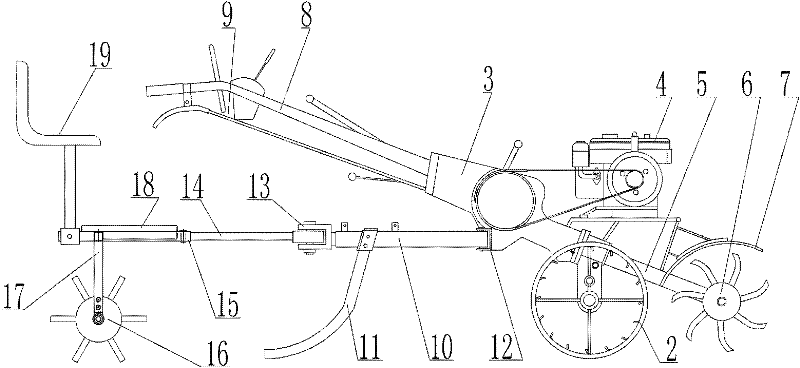

[0013] Example Example 1, from figure 1 It can be seen that the present invention includes a recoil bracket composed of a rear seat side strut 17 and a rear seat crossbeam 20, a rear roller 16 and a stool body 19, and the upper ends of the two rear seat side struts 17 are fixedly connected to the rear seat crossbeam 20 respectively. The two ends of the rear seat crossbeam 20 are positioned at the flush position of the rear seat crossbeam 20 tops at the front of the rear seat crossbeam 20, and the footrest support 22 is fixed to form a stool support, and the footrest 18 and the stool are installed on the top of the stool support. Body 19, and the rear connection sleeve 15 is fixed on the front of the stool bracket, so as to be connected with the power tillage device at the front; at the same time, the lower ends of the two rear seat side support rods 17 are respectively fixed with shaft sleeves 23 , the axle sleeve 23 can be fixedly installed with the lower end of the rear seat...

example example 2

[0014] Example 2, see figure 1 , the present invention also can install the stool body 19 on the stool support 29 by installing the stool support 29 at the rear portion of the stool support. refer to Figures 1 to 3 , all the other are with embodiment 1.

example example 3

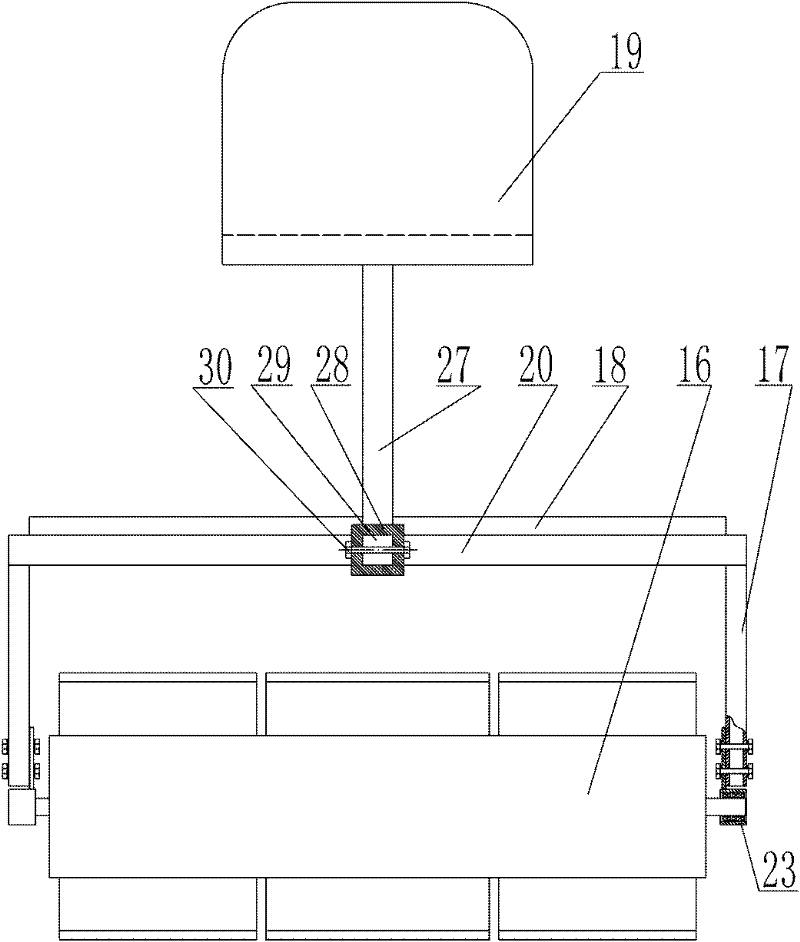

[0015] Example 3, see figure 2 , the present invention can connect the stool support rod 27 at the bottom of the stool body 19, the bottom of the stool support rod 27 is fixedly connected to the support rod sleeve 28, and the support rod sleeve 28 is set on the stool support 29, The support pin 30 is set between the support rod sleeve 28 and the stool support 29 , so that the stool body 19 is set. refer to Figure 1 to Figure 3 , all the other are with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com