On-line automatic measurement method for Mooney viscosity of rubber

A Mooney viscosity, automatic measurement technology, applied in the field of rubber tire manufacturing, can solve the problems of reduced production efficiency, reduced production efficiency of enterprises, unguaranteed processing performance, etc., to ensure reliability, reduce rubber parking time, and ensure continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

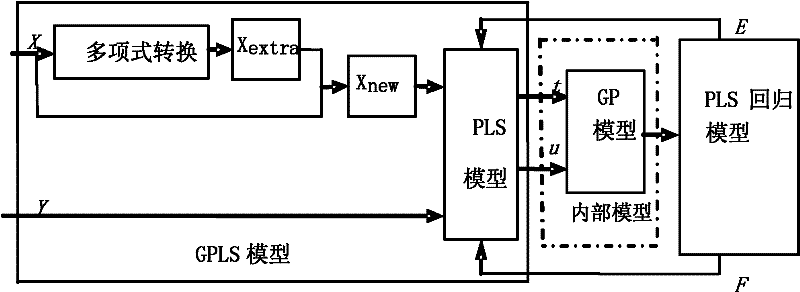

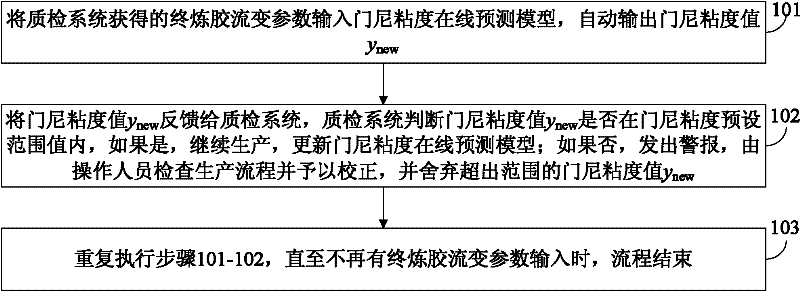

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The indicators detected by the rheometer are an important part of the rubber quality system. Usually, the detection time is short, only about 2 minutes, and it does not need to be parked for detection. Investigations have shown that there is a strong relationship between rheological indicators and Mooney viscosity. Therefore, estimating or predicting Mooney viscosity through rheological parameters is an effective way to solve the problem of Mooney viscosity detection.

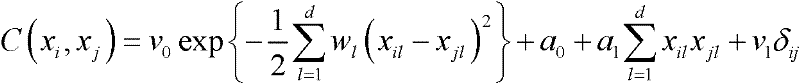

[0033] The parameters detected by the rheometer reflect to a certain extent that the rubber quality and processing performance are important components of the rubber quality system. Mainly include minimum torque, maximum torque and curing time parameters. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com