A method for online prediction of Mooney viscosity of rubber compounded by open-kneader

A technology of Mooney viscosity and prediction method, which is applied in the field of on-line prediction of Mooney viscosity of rubber mixing rubber in a rubber mill, can solve problems such as the Mooney viscosity of rubber mixing without an open mill, and achieves saving parking time, simple control, and The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

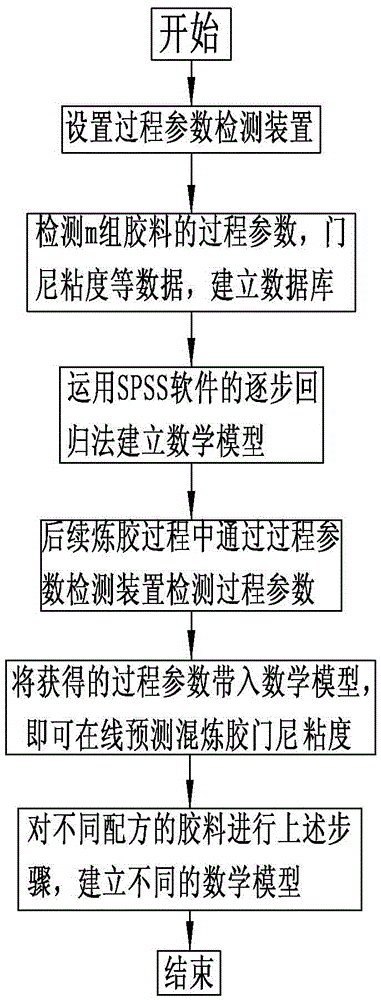

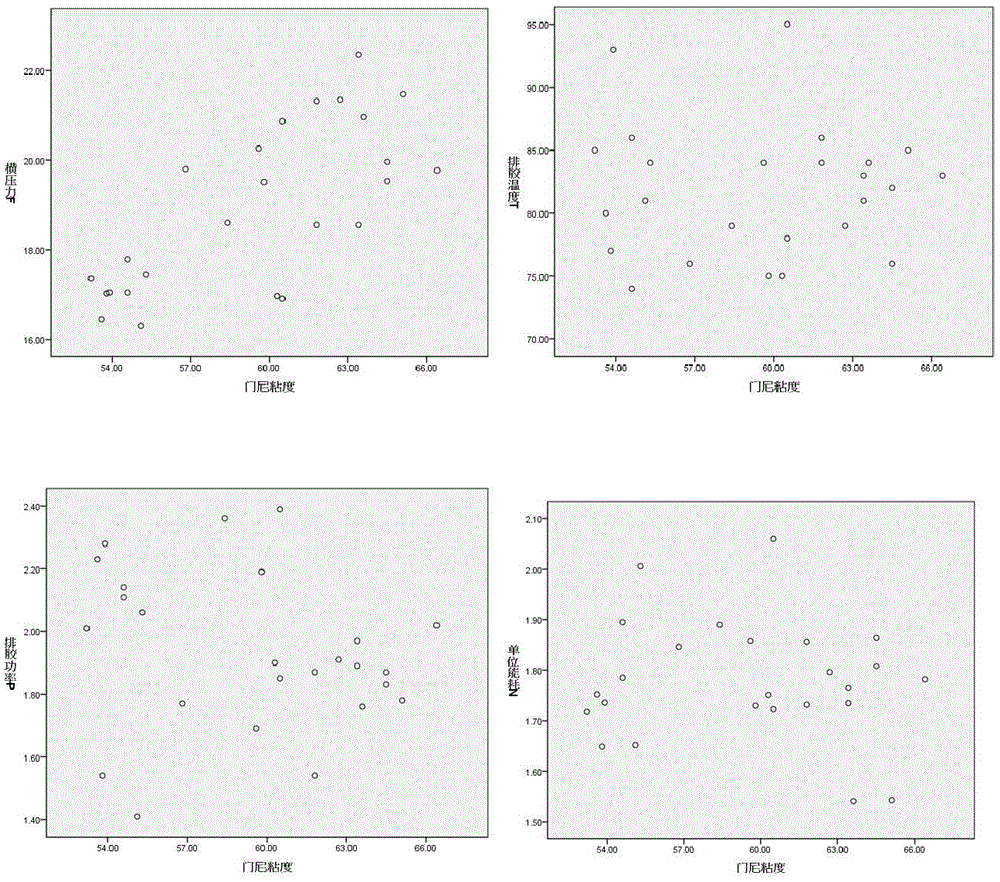

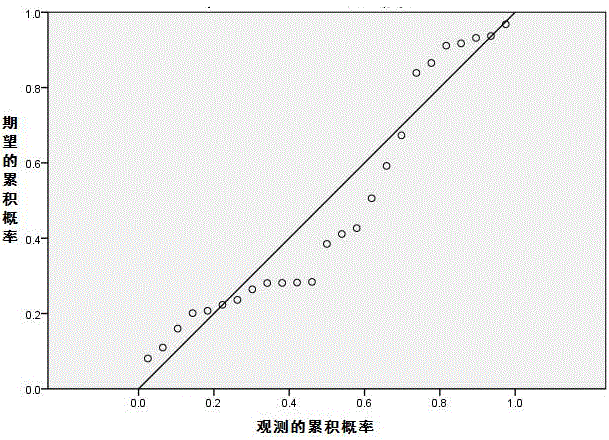

[0027] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0028](1) The rubber material used in this example is all-steel radial tire tread rubber, which is mixed using an XK-160E open mill intelligent rubber mixing experimental platform. Prepare 25 groups of formula rubber materials to be verified, and their formulas are shown in Table 1:

[0029] Table 1

[0030]

[0031] (2) In order to avoid environmental pollution and powder loss caused by flying dust when adding powder to the open mill for rubber mixing, before performing rubber mixing with the open mill, use the internal mixer for preliminary plasticizing and mixing, the most important The purpose is to mix the rubber material, powder material and oil material together with the internal mixer first, so as to facilitate the subsequent rubber mixing operation of the open mixer. After the rubber is discharged from the internal mixer, the rubber material...

Embodiment 2

[0043] The present invention is further described by common conveyor belt formula and in conjunction with accompanying drawing:

[0044] (1) The rubber used in this example is a common conveyor belt formula, and the XK-160E open mill intelligent rubber mixing experimental platform is used for mixing. Prepare 25 groups of formula rubber materials that need to be verified, and their formulas are shown in Table 4:

[0045] Table 4

[0046]

[0047] (2) In order to avoid environmental pollution and powder loss caused by flying dust when adding powder to the open mill for rubber mixing, before performing rubber mixing with the open mill, use the internal mixer for preliminary plasticizing and mixing, the most important The purpose is to mix the rubber material, powder material and oil material together with the internal mixer first, so as to facilitate the subsequent rubber mixing operation of the open mixer. After the rubber is discharged from the internal mixer, the rubber m...

Embodiment 3

[0059] The present invention will be further described by the formula of ordinary hose inner layer glue in conjunction with the accompanying drawings:

[0060] (1) The rubber used in this example is the formula of ordinary rubber hose inner layer, and the XK-160E open mill intelligent rubber mixing experimental platform is used for mixing. Prepare 25 groups of formula rubber materials to be verified, and their formulas are shown in Table 1:

[0061] Table 7

[0062]

[0063] (2) In order to avoid environmental pollution and powder loss caused by flying dust when adding powder to the open mill for rubber mixing, before performing rubber mixing with the open mill, use the internal mixer for preliminary plasticizing and mixing, the most important The purpose is to mix the rubber material, powder material and oil material together with the internal mixer first, so as to facilitate the subsequent rubber mixing operation of the open mixer. After the rubber is discharged from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com