Nano coating film insulation glass

A nano heat-insulating and heat-insulating glass technology, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of high cost of energy-saving glass, and achieve high lighting, high isolation of infrared rays and ultraviolet rays Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings and implementation examples, and the present invention includes but not limited to the given implementation examples.

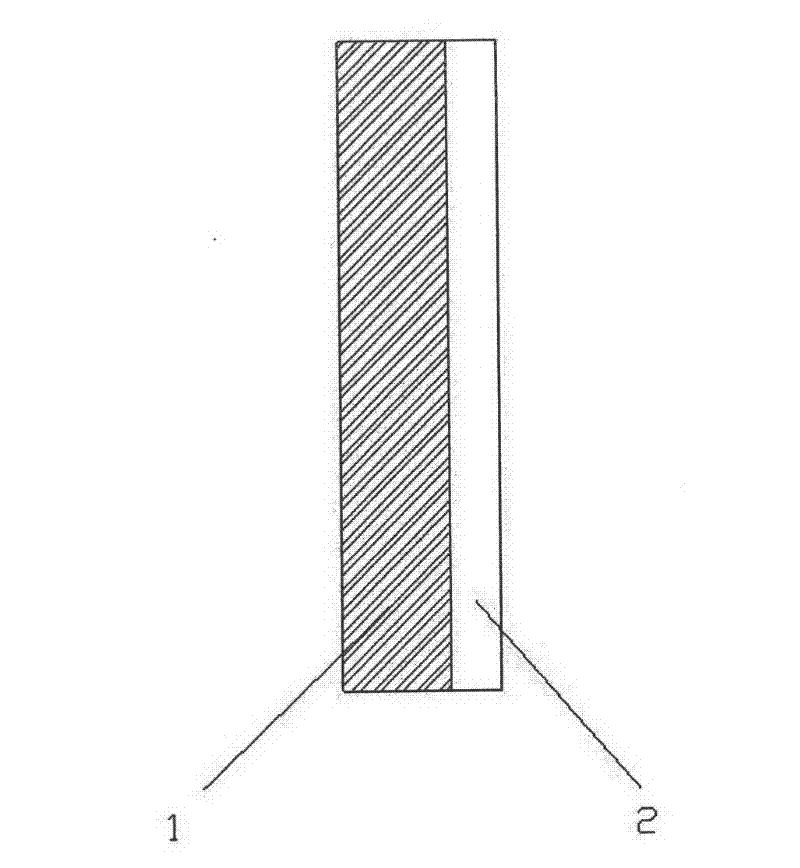

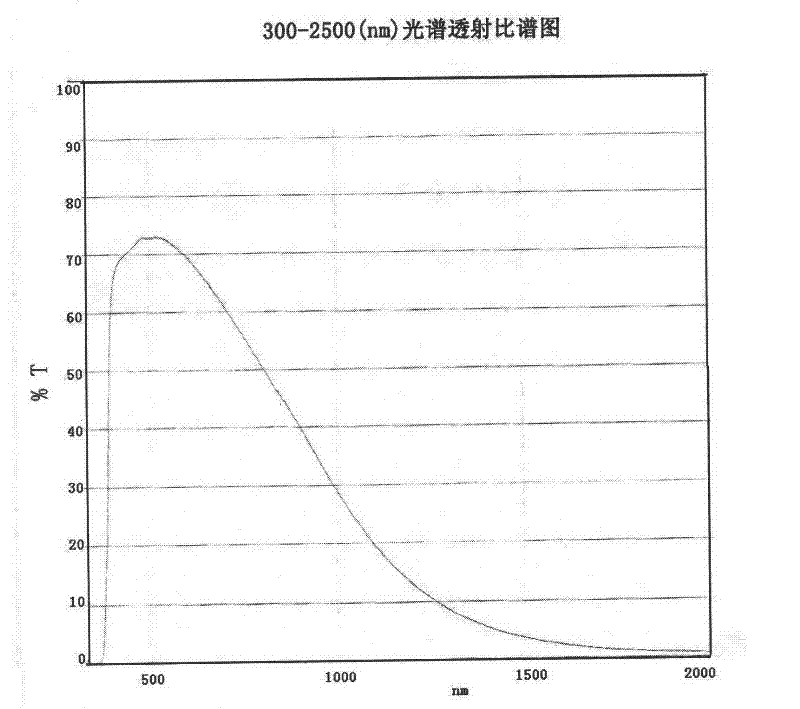

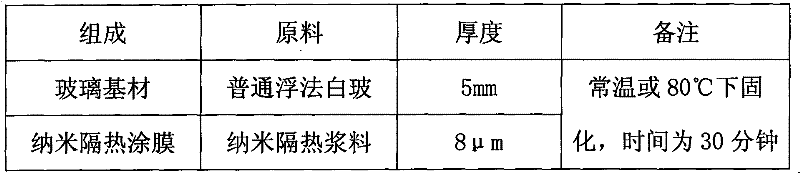

[0029] Such as figure 1 As shown, the nano-coated heat-insulating glass involved in the embodiment of the present invention roll-coats the nano-coated heat-insulating coating 2 on the surface of the glass substrate 1 to form a coating with a thickness of 8 μm. The composition of the glass of the present invention and the composition of the coating film As shown in Table 1 and Table 2:

[0030] Table 1: Composition of nano-coated insulating glass:

[0031]

[0032] Table 2: Composition of nano heat insulation coating film:

[0033]

[0034]

[0035] The nano heat-insulating coating film is rolled on the glass base surface through the roll-coating equipment independently designed by our company, and the heat-insulating glass of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com