Vehicle-posture adjusting system tire load control method

A technology of adjustment system and control method, applied in vehicle components, elastic suspension, suspension and other directions, can solve problems such as unreasonable wheel load distribution, and achieve the effect of reasonable pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

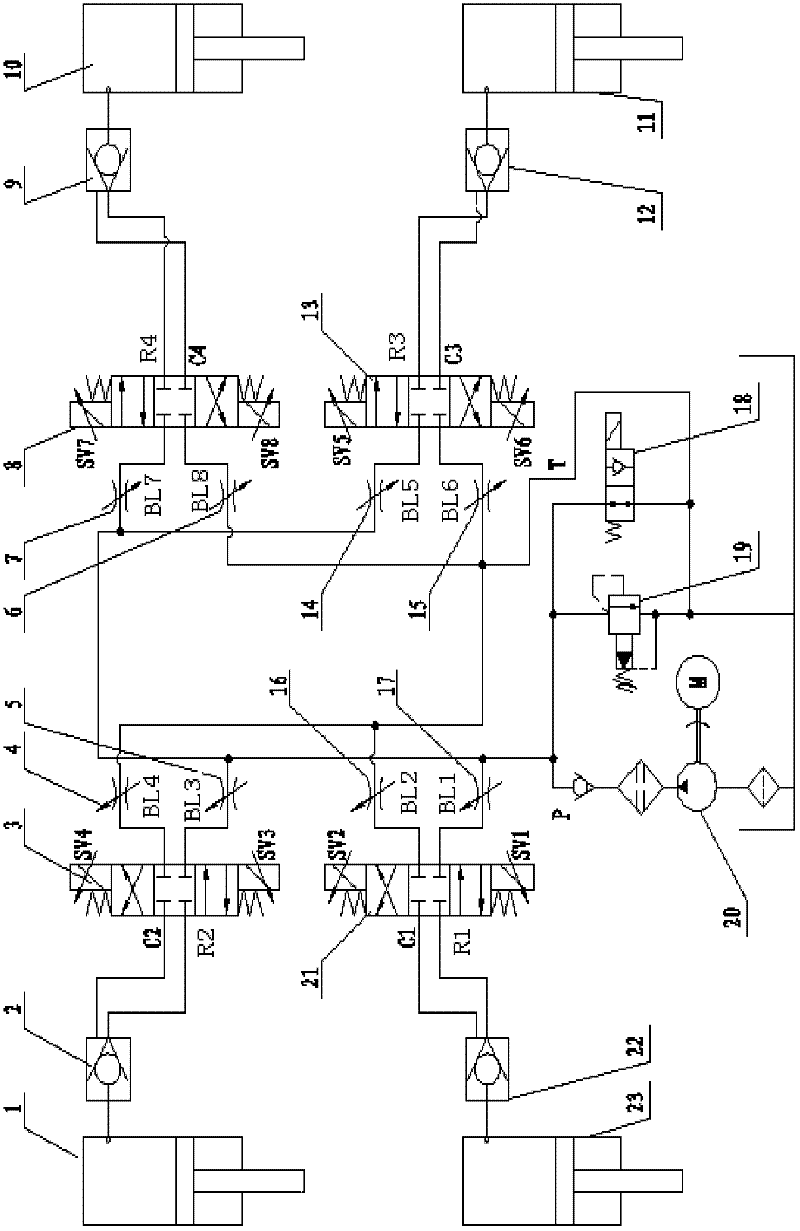

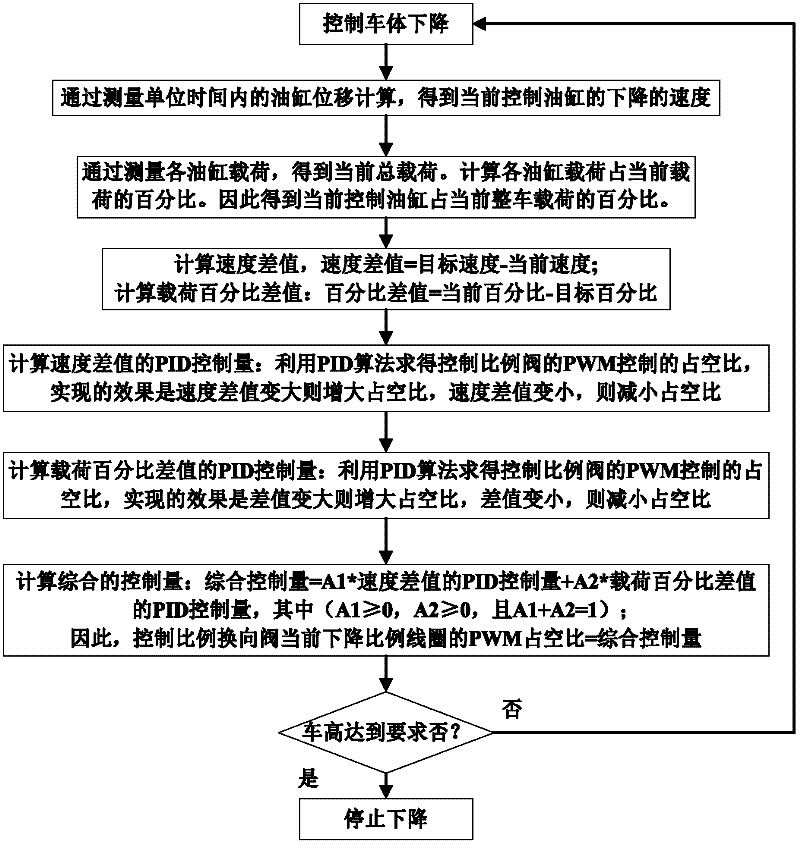

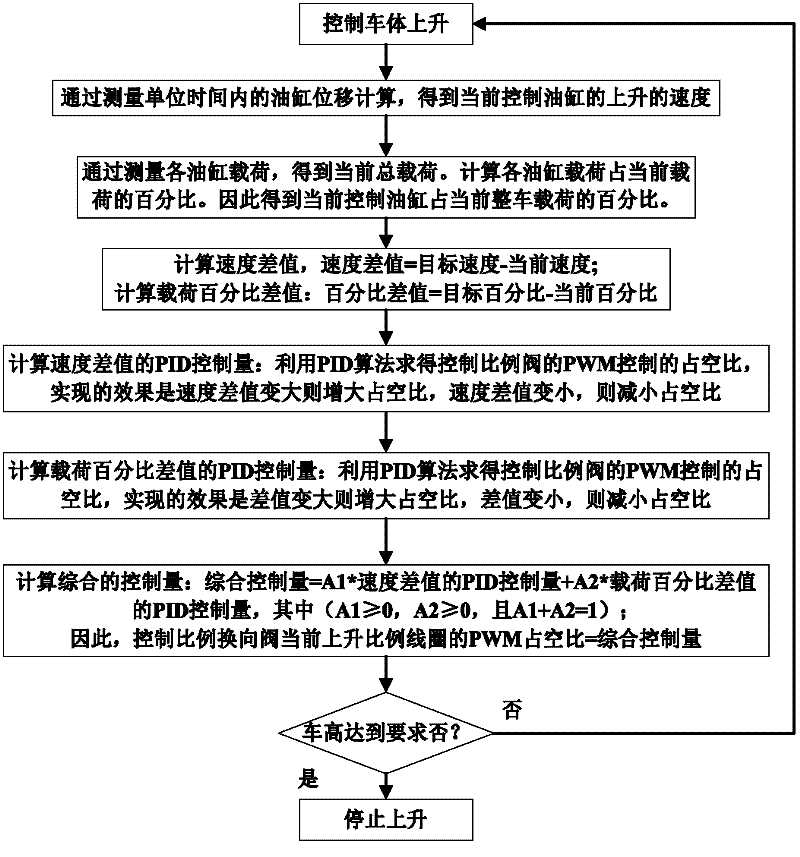

[0042] Such as Figure 1-3 As shown, a vehicle attitude adjustment system tire load control method of the present invention, the vehicle attitude adjustment system includes: suspension, fuel tank, hydraulic pump 20, hydraulic control check valve 22, hydraulic control check valve 2, hydraulic control Check valve 9, hydraulic control check valve 13, three-position four-way proportional directional control valve 21, three-position four-way proportional directional control valve 3, three-position four-way proportional directional control valve 8, three-position four-way proportional directional control valve 13. Adjustable throttle valve 17, adjustable throttle valve 16, adjustable throttle valve 5, adjustable throttle valve 4, adjustable throttle valve 7, adjustable throttle valve 6, adjustable throttle valve 14, adjustable throttle valve 15, Oil cylinder 23, oil cylinder 1, oil cylinder 10, oil cylinder 11, two-position two-way valve 18;

[0043] The hydraulic pump 20 is driven...

Embodiment 2

[0062] Such as Figure 1-3 As shown, a tire load control method of a vehicle posture adjustment system invented in this example, the system and steps are basically the same as those in Embodiment 1, the difference is that:

[0063]Step 3. Set a basic difference. The value of the basic difference depends on the control accuracy requirements of the vehicle height adjustment and the accuracy that the sensor can achieve. The result obtained by comparing the detected current vehicle height with the target vehicle height and the basis The differences are compared and processed in three cases.

[0064] a. When the result obtained by comparing the detected current vehicle height with the target vehicle height is greater than the base difference, the vehicle height is adjusted downward, and the adjustment method and steps are completely consistent with embodiment 1;

[0065] b. When the detected current vehicle height is compared with the target vehicle height and the result obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com