Dynamic stall control method based on dynamic sagging of leading edge of wing

A wing leading edge and dynamic stall technology, applied in the direction of heat reduction structure, etc., can solve the problems of low jet flow, single optimal working condition of vortex generator, and weak control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

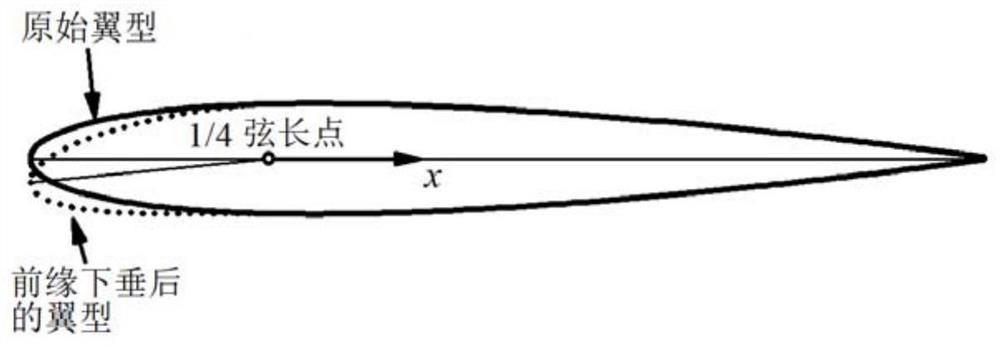

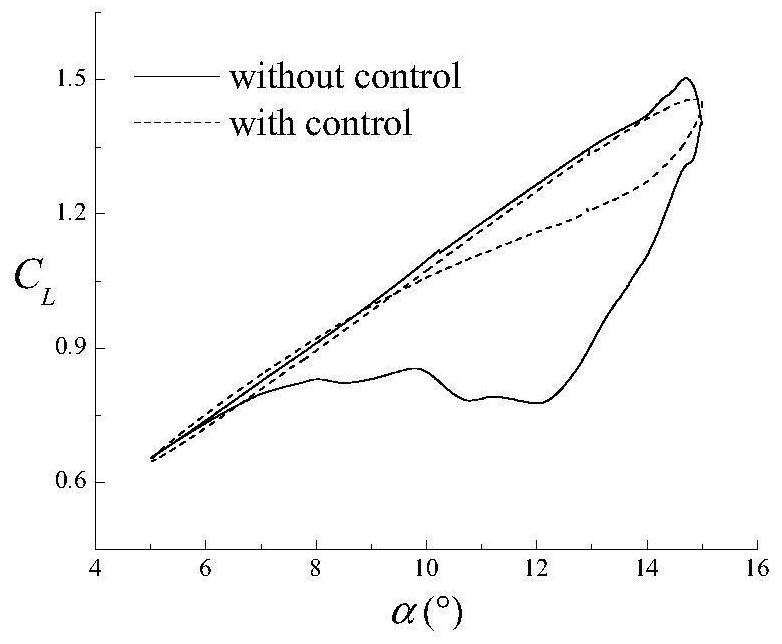

[0024] The invention provides a dynamic stall control method based on the dynamic drooping of the leading edge of the wing. The local effective angle of attack at the small leading edge makes the pressure distribution of the wing more reasonable, reduces the reverse pressure gradient near the leading edge, and makes separation less likely to occur; The edge returns to its original shape from the drooping state, thereby better maintaining the aerodynamic characteristics of the original airfoil.

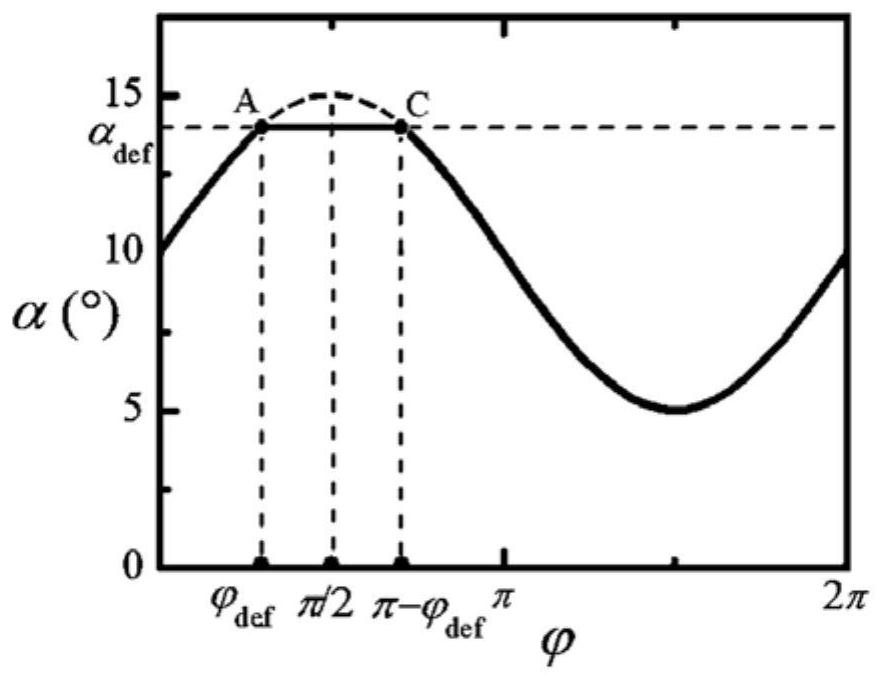

[0025] The drooping mode of the leading edge of the wing is as attached figure 1 shown. attached figure 2 It shows the variation of the angle of attack of the wing as a whole and the leading edge with time, and the horizontal axis represents the phase angle, which is the product of time and angular frequency—φ=ωt, so time can also be represented when the angula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com