A kind of mesh extruder and scr catalyst manufacturing process based on extruder

An SCR catalyst and extruder technology, applied in physical/chemical process catalysts, die extrusion granulation, chemical instruments and methods, etc., can solve problems such as prolonged end face adjustment time, low extrusion efficiency, and protruding parts. , to achieve the effect of stable internal state, reasonable pressure distribution and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

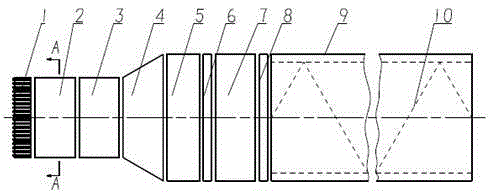

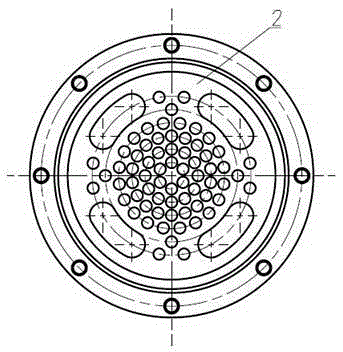

[0030] Such as figure 1 , 2 As shown, a mesh extruder includes a die section 1, an equalizing section 2, a micro-compression section 3, a circular intersection section 4, a transition section 5, an equalizing plate 6, a transition section 2 7, a support plate 8, Extrusion molding section 9, and extrusion screw rod 10; mold section 1 is connected with pressure equalizing section 2, pressure equalizing section 2 is connected with micro-compression section 3, micro-compression section 3 is connected with circle intersection square section 4, circle intersection square section 4 is connected with the transition section one 5, the transition section one 5 is connected with the pressure equalizing plate 6, the pressure equalizing plate 6 is connected with the transition section two 7, the transition section two 7 is connected with the support plate 8, the support plate 8 is connected with the extruder 9, extruded The screw rod 10 is connected to the extrusion section 9 .

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com