Steel bar bundling mechanical hand and special buckle element thereof

A technology of manipulators and steel bars, which is applied to the parts of strapping machines, strapping materials, flexible and slender components, etc., can solve the problems of restrictions on the popularization and application of strapping machines, low recycling rate of wire coils, and increased use costs, etc., to achieve the goal of using Wide range, safe use, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

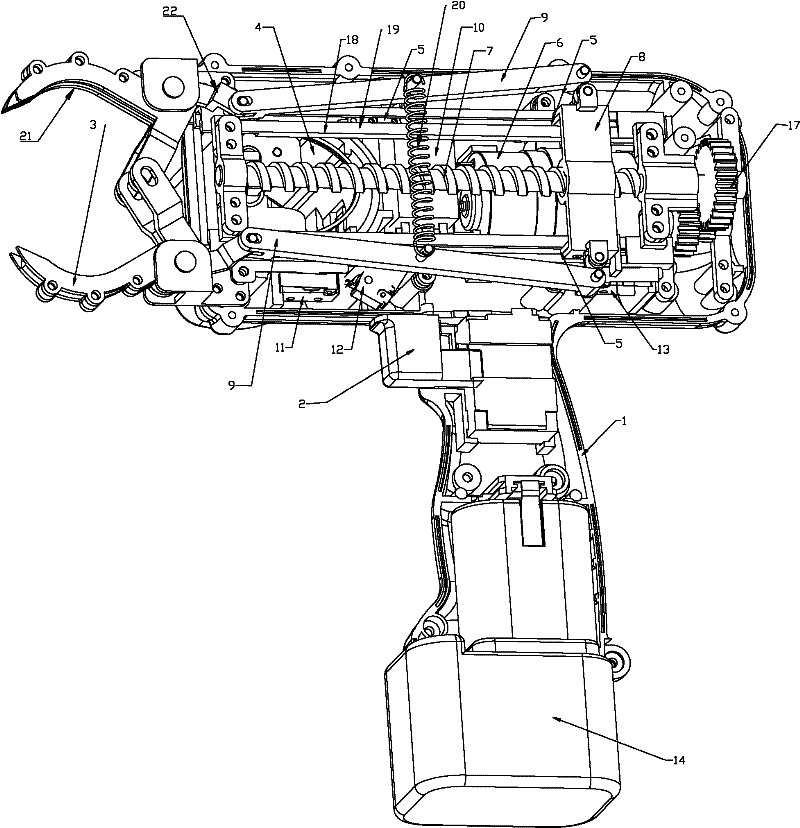

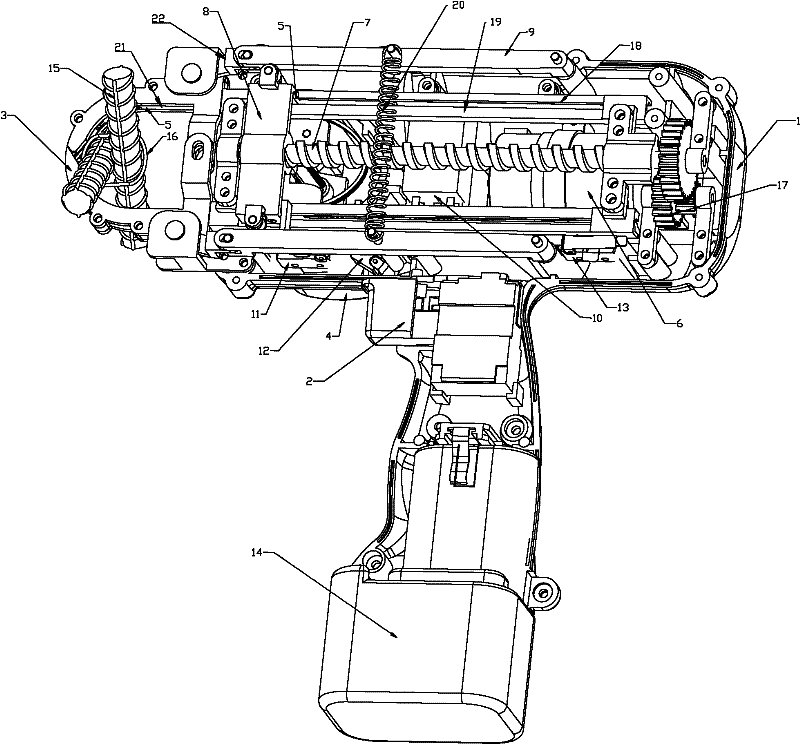

[0040] like figure 1 Shown: a steel bar binding manipulator, including a body 1, is characterized in that it is composed of the following parts: a holding mechanism installed on the outer end of the body to hold the binding fastener, and a loading mechanism installed on the inside of the body to bind the fastener, and The sending mechanism of the binding fastener that pushes out the binding fastener from the loading mechanism and sends it into the holding mechanism, and the power mechanism that drives the sending mechanism to move back and forth by rotation, and makes the holding mechanism close and open connecting rod drive mechanism.

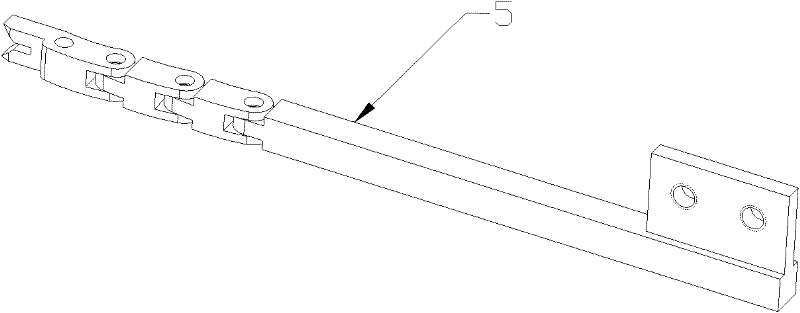

[0041] The sending device of the binding fastener is composed of a gear device 17, a guide screw 7, a screw sleeve 8, two upper and lower guide rods 19, and two upper and lower chain pushers 5. The gear device 17 is installed behind the body 1 end, the rear end of the guide screw 7 is connected to the gear device 17, the front end is fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap