Lifting-type ship cabin conveyor

A conveyor and lift-type technology, applied in the field of lift-type cabin conveyors, can solve problems such as overturning accidents, smashed equipment, and item damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

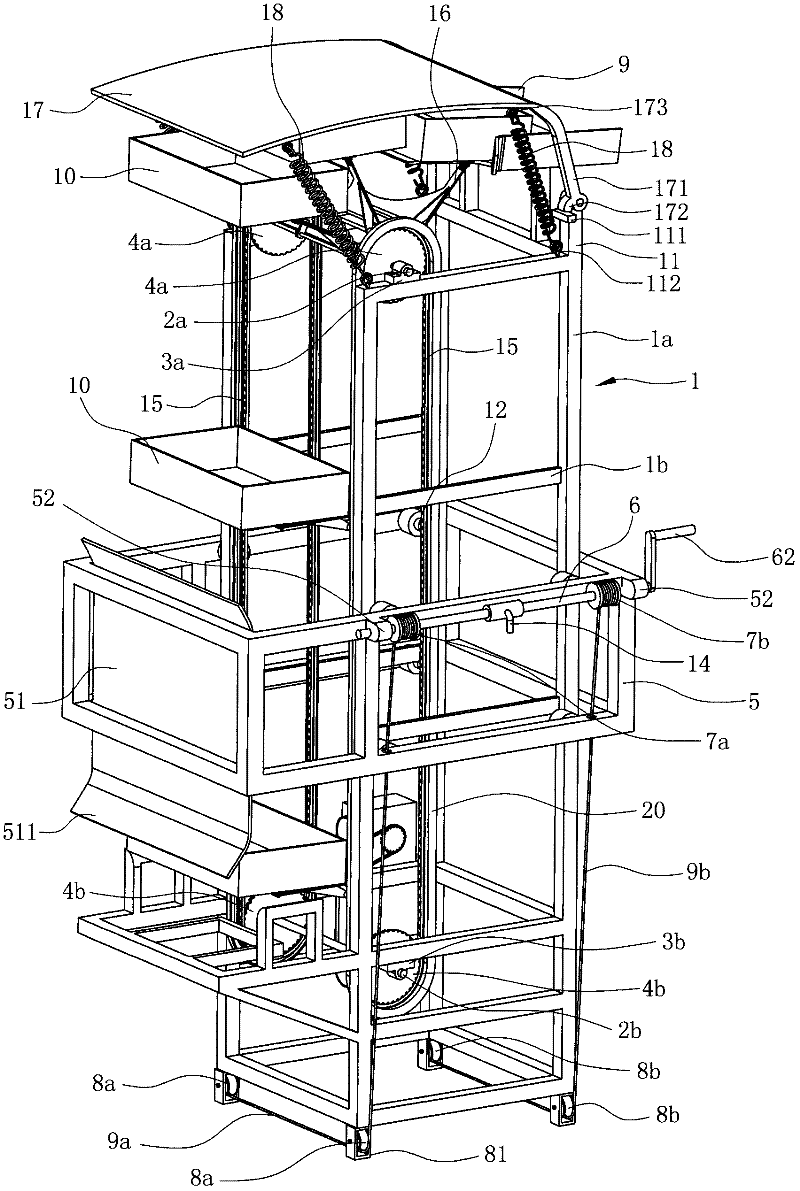

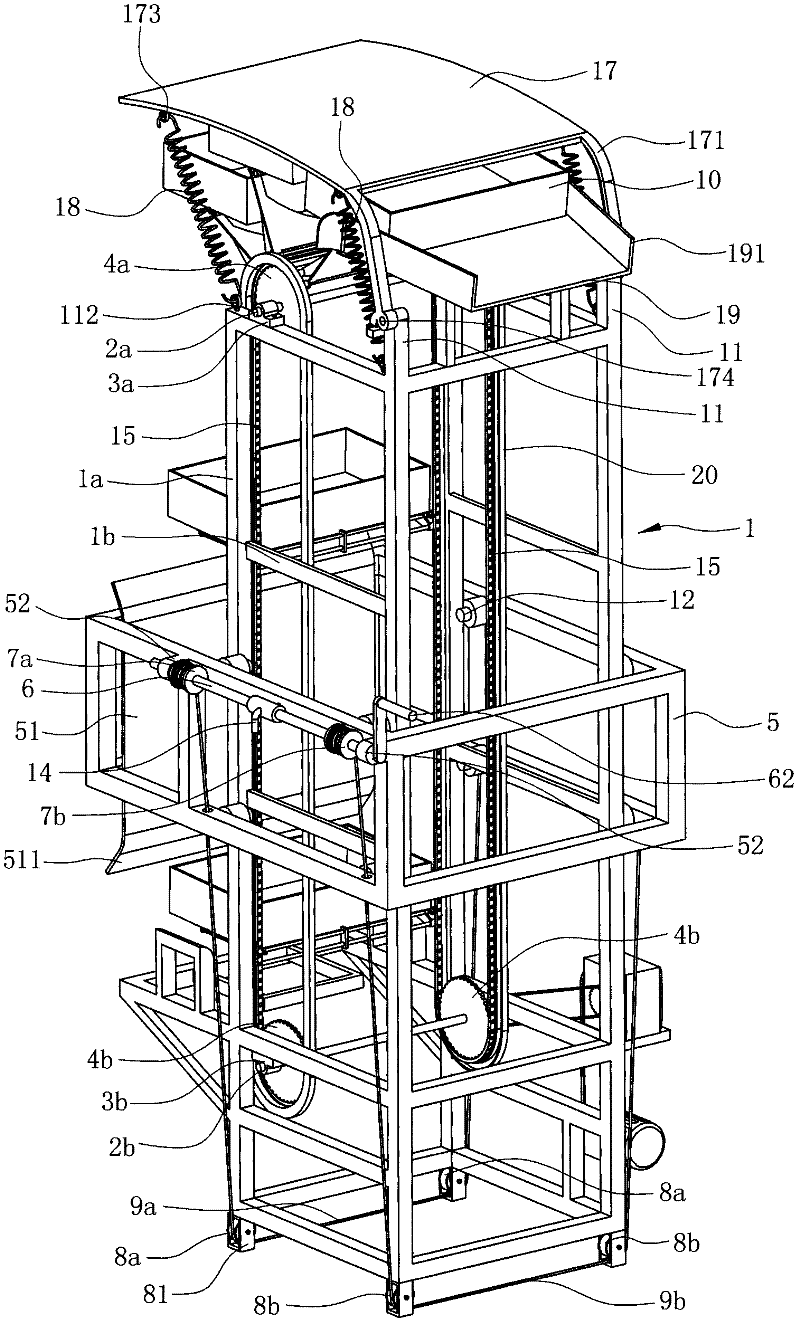

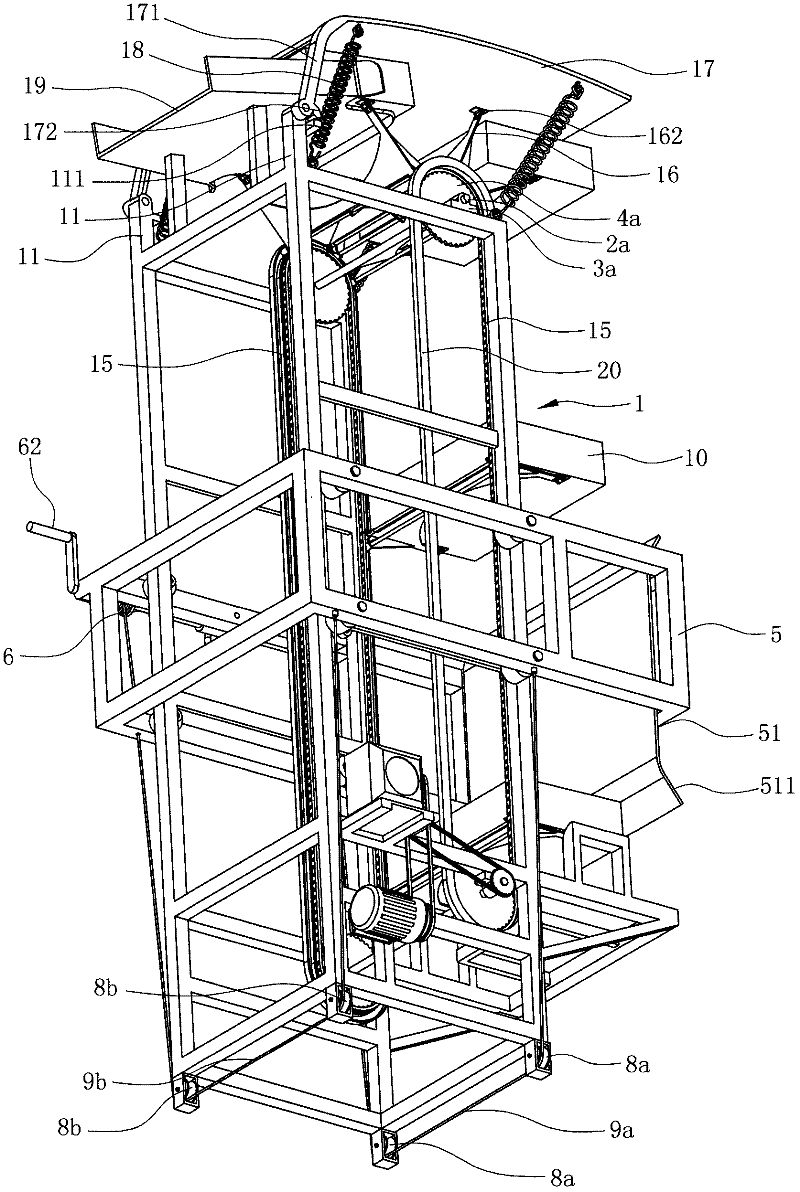

[0033] Such as Figure 1-10 Shown is a preferred embodiment of the present invention.

[0034] An elevating cabin conveyor, comprising a frame 1, the frame 1 is a cuboid frame composed of four uprights 1a and several cross bars 1b connecting adjacent two vertical bars 1a, the frame 1 is provided with The chain drive lifting device that lifts the box body 10 from the bottom of the frame 1 to the top of the frame 1 .

[0035] Peripheral frame 5, which is a rectangular parallelepiped frame structure, frame 1 is installed in this peripheral frame 5 and can slide up and down; Position shaft 12; guide plate 51 is fixed on the front inner wall of peripheral frame 5, and the bottom of guide plate 51 is the arc portion 511 that bends outwards, and between guide plate 51 and the front end face of frame 1 there is a box body 10 to pass through. Pitch. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com