Ethyl maltol chlorination continuous production method and device

A technology of ethyl maltol and production method, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

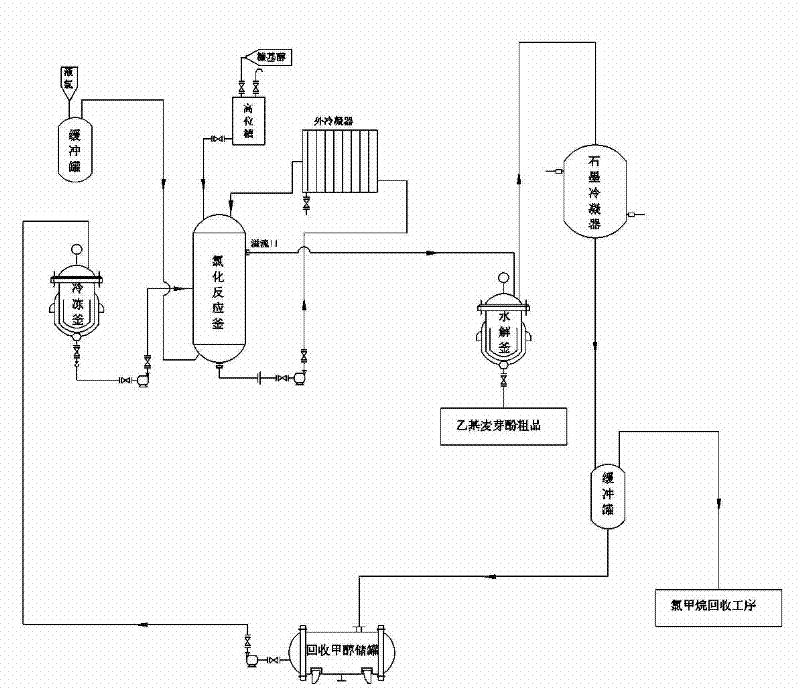

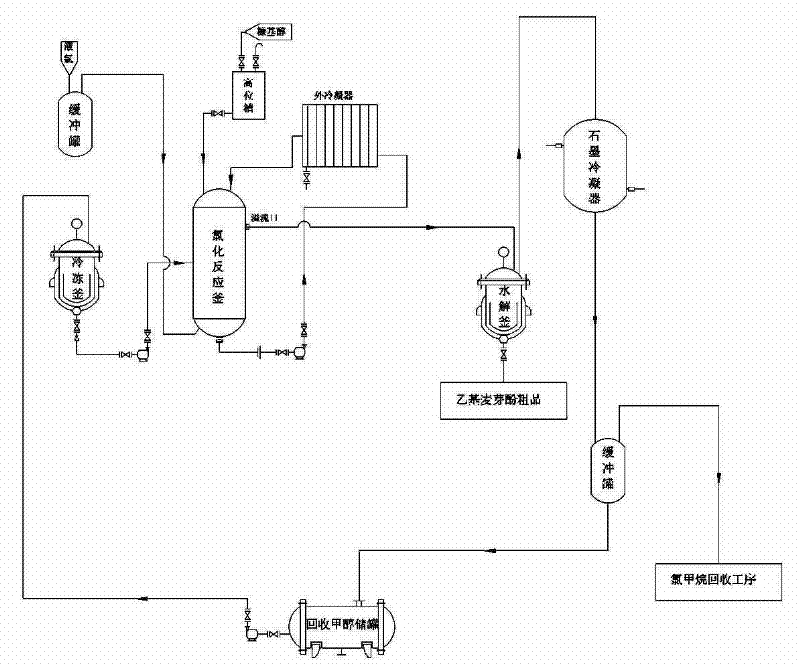

Image

Examples

Embodiment Construction

[0019] A kind of ethyl maltol chlorination continuous production method provided by the invention comprises the following steps:

[0020] a. Continuously feed the methanol solution recovered by hydrolysis into the chlorination reaction kettle at a rate of 100L / h. The chlorination reaction kettle turns on the external circulation refrigeration. Furfuryl alcohol is continuously added dropwise into the chlorination reaction kettle, and chlorine gas is continuously introduced at a rate of 30kg / h at the same time. The heat of reaction is exchanged by the circulating pump through the external cooling heat exchanger. The position rises to the automatic overflow port, and automatically overflows to the hydrolysis reactor;

[0021] b. After the reactant enters the hydrolysis kettle, steam it to 90°C. At this time, the by-products in the chlorination reaction, methyl chloride and methanol, are steamed out, and the crude ethyl maltol is discharged from the hydrolysis kettle at a speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com