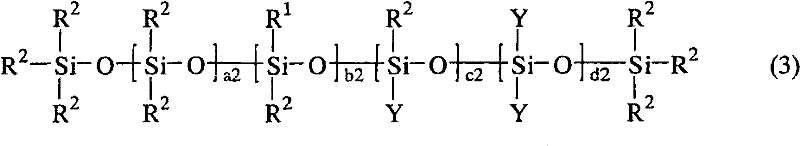

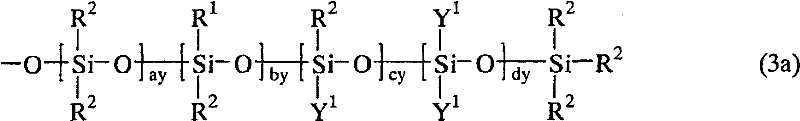

Primer silicone composition and treated paper or film for release paper or film

一种有机硅、组合物的技术,应用在底漆、薄料处理、纺织品和造纸等方向,能够解决改善有机硅组合物粘合性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-17

[0185] Embodiment 1-17, comparative example 1-8

[0186] Components (A) and (B) were mixed in the amounts shown in Table 1 to prepare a primer silicone composition. The composition is coated with a coating weight of 0.005g / m 2 Coated onto PET or OPP substrates with an integral dose of 50mJ / cm at a line speed of 40m / min 2 It was exposed to UV radiation from two 80-W bulbs and heat treated at 80° C. for 10 seconds in a hot air circulating dryer to form a primed substrate.

[0187] Components (C), (D) and (F) in the amounts shown in Table 1 and (E) in an amount capable of providing 100 ppm platinum based on the total weight of (C)+(D) were mixed to prepare the overlying composition or stripping composition. The release silicone composition is 0.5g / m 2 Coating Weight Coating was applied on a primed substrate, and heat-cured at 100° C. for 30 seconds to form a release film, which was evaluated according to the evaluation method described later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com