Engine balance shaft oil pressure releasing structure

A balance shaft and engine technology, applied in the direction of controlling lubricant pressure, etc., can solve problems such as unreliable work of the balance shaft, damage to the balance shaft mechanism, loose bearings, etc., to improve driving comfort, avoid loose bearings, and extend service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

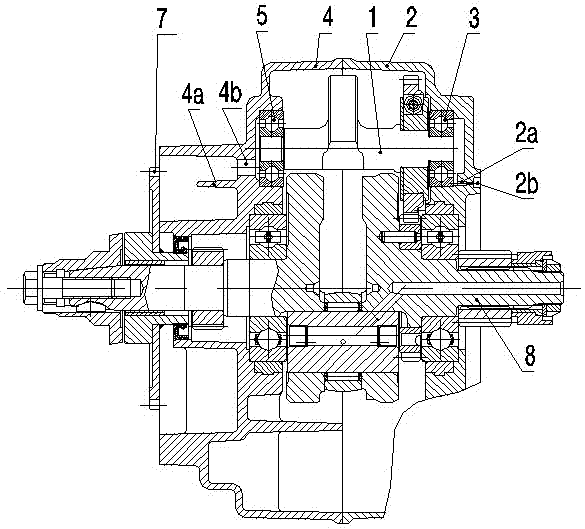

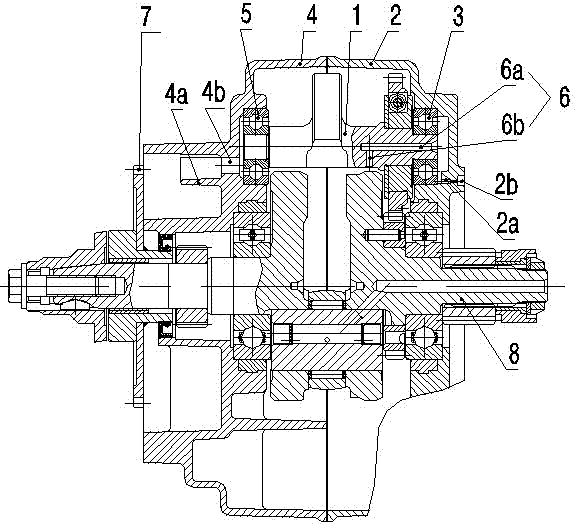

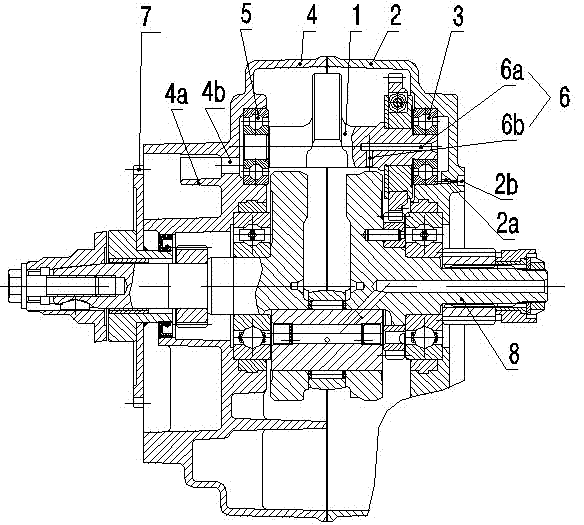

[0010] figure 2 The shown engine balance shaft unloading oil pressure structure consists of a balance shaft 1, a right crankcase 2, a first bearing 3 installed on the right crankcase 2, a left crankcase 4, and a second bearing installed on the left crankcase 4 5. Composition of starting gear 7, crankshaft 8, etc. The right side of the balance shaft 1 is journaled on the first bearing 3 , and the left side of the balance shaft 1 is journaled on the second bearing 5 . The balance shaft 1 is set parallel to the crankshaft 8, the gear on the crankshaft 8 meshes with the gear on the balance shaft 1, the crankshaft 8 drives the balance shaft 1 to rotate together, and a starting gear 7 is installed on the left side of the crankshaft 1, and the starting gear 7 is set on The left side of the left crankcase 4. The right side of the right crankcase 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com