Fatigue and strength test table of wind-power blade

A strength test, wind power blade technology, applied in the direction of using stable tension/pressure test material strength, machine/structural component test, vibration test, etc., can solve problems such as lack of industry standards, to ensure uniqueness and reduce requirements , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

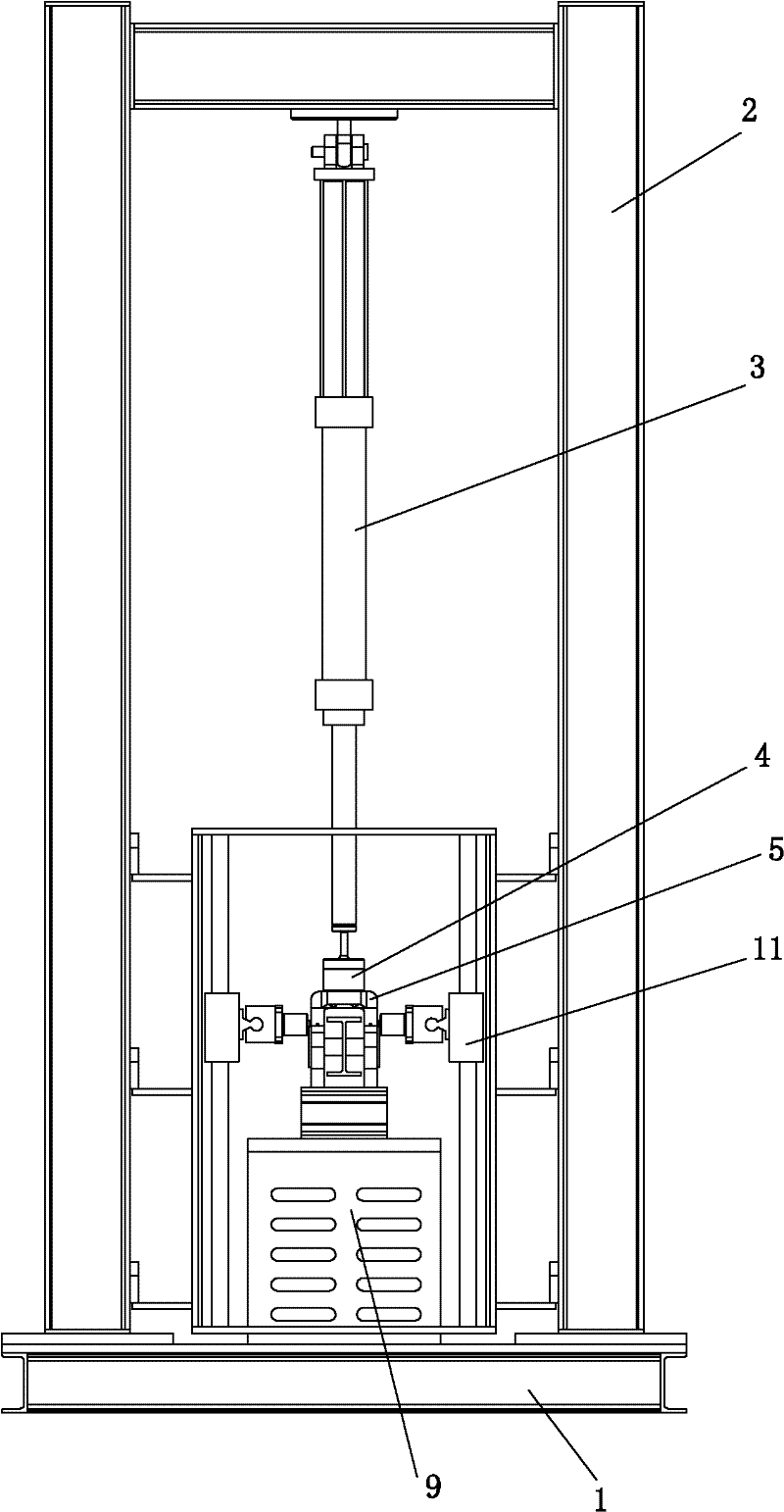

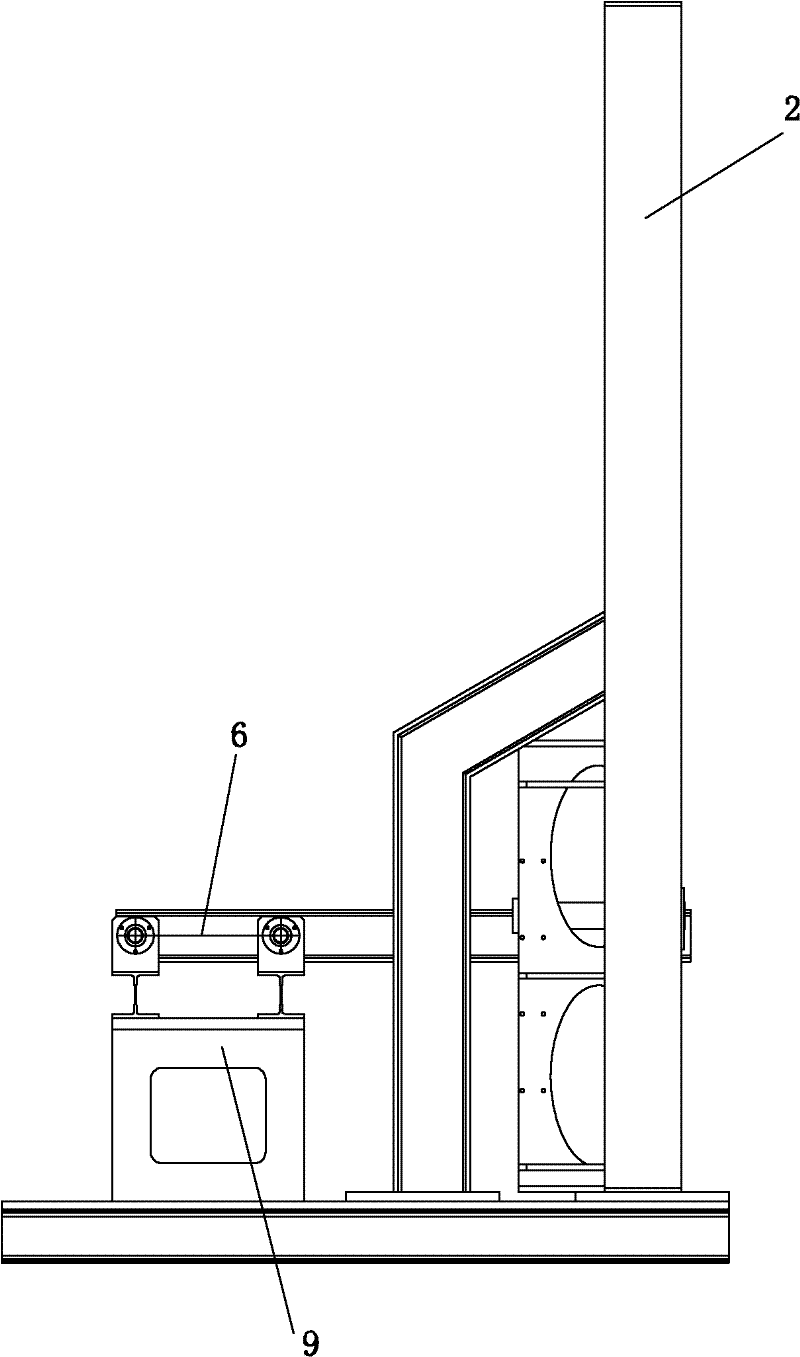

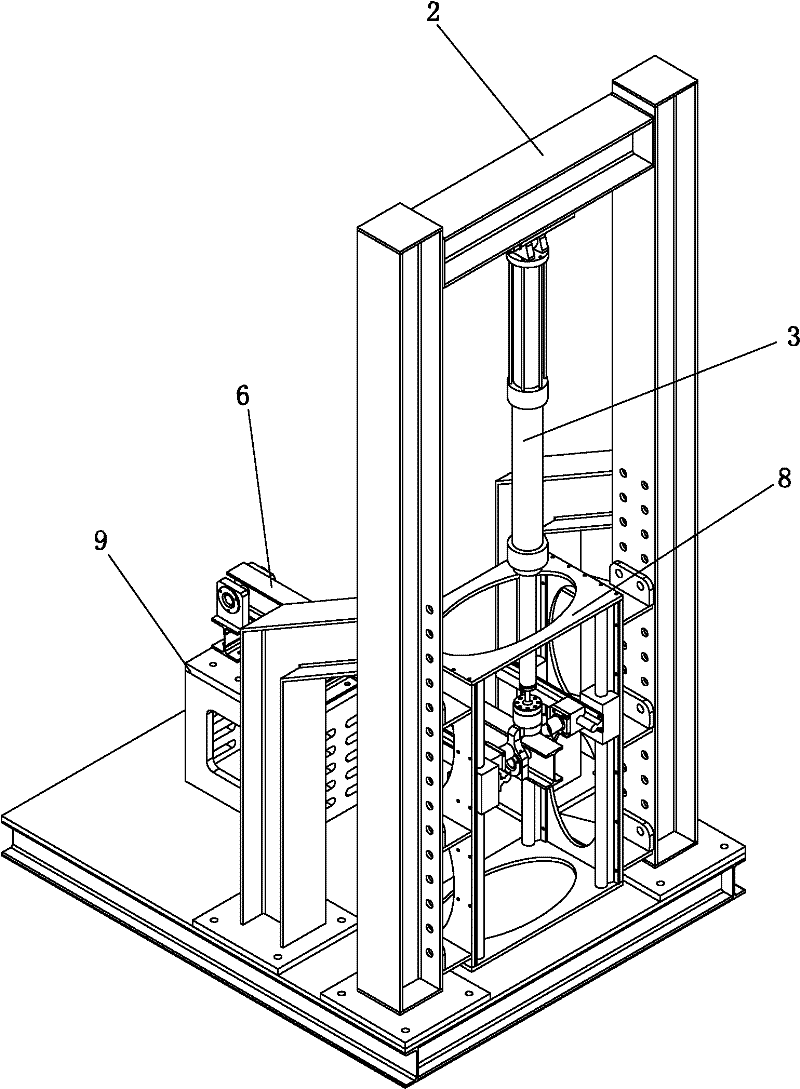

[0013] See Figure 1-4 , the fatigue and strength test bench of the wind power blade of the present embodiment comprises: a base 1, a main frame 2 arranged on the base 1, a double-piston rod oil cylinder 3 whose top is hinged on the upper beam of the main frame 2, and a double-piston rod oil cylinder 3 The downward protruding end of the piston rod 3-1 is sequentially connected with the force transmission part 4 and the transition joint 5; a force sensor is arranged between the force transmission part 4 and the transition joint 5; the H-type test piece 6 is connected to the transition joint 5 The joint 5 is connected by a pin shaft 7; the double piston rod cylinder 3 is provided with a displacement sensor for detecting the longitudinal displacement of the H-type test piece 6; an inner frame 8 is fixed in the main frame 2, and a vertical The sliding fitting mechanism 11 and the horizontal sliding fitting mechanism 10, the transition joint 5 is set on the vertical sliding fitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com