Test method and apparatus for simulating actual pavement cracking through crack

A technology of reflection cracks and test devices, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve problems such as differences, and achieve the effects of high data accuracy, increased convenience, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

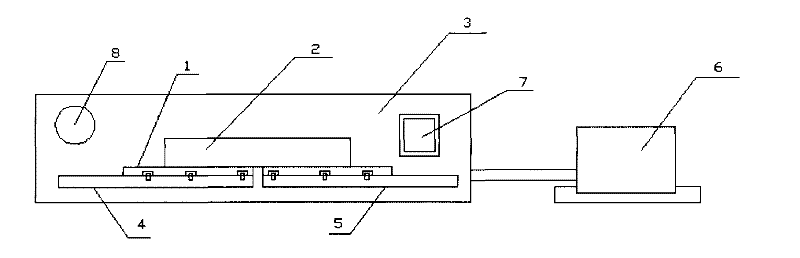

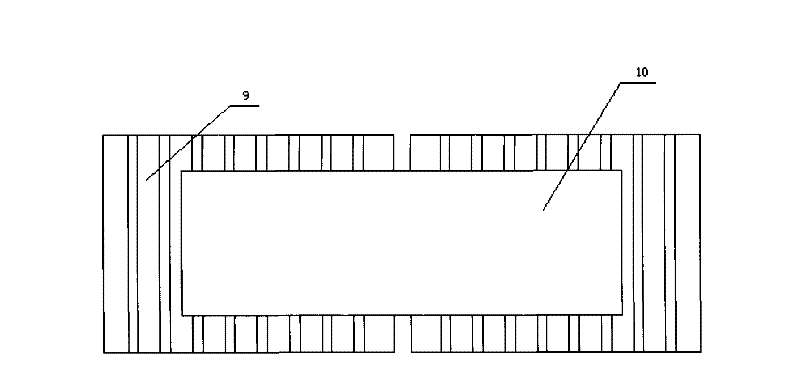

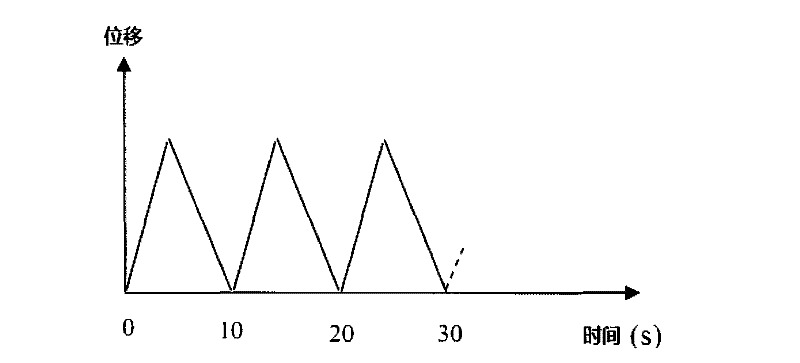

[0031] Reference figure 1 , figure 2 , A test device for simulating actual road cracking through reflection cracks, including environmental box 3, data acquisition system 6, testing machine 7, measurement system 8, and asphalt pavement simulation platform 9. The test piece 2, the testing machine 7, the measurement system 8, and the asphalt pavement simulation platform 9 are all located in the environmental box 3. The testing machine 7 is connected to the asphalt pavement simulation platform 9 for loading, and the measurement system 8 is connected to the asphalt simulation platform 9 Used to measure the deformation parameters in the test. The measurement system 8 is connected to the data acquisition system 6 for collecting test data.

[0032] The measurement system 3 includes a temperature sensor, a force sensor, and a time deformation observer.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com