Method for optimizing reliability of harmonic gear used for space vehicle based on fault physics

A technology of harmonic gear and fault physics, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of difficult to determine the main failure mode and functional function of the system, shorten the product design cycle and reduce the launch cost. , the effect of reducing the cost of product development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described: a kind of reliability optimization method of harmonic gear used in spacecraft based on failure physics, comprises the following steps:

[0019] Step 1: Establish the physical model of the harmonic gear for spacecraft according to the structural characteristics of the harmonic gear for spacecraft.

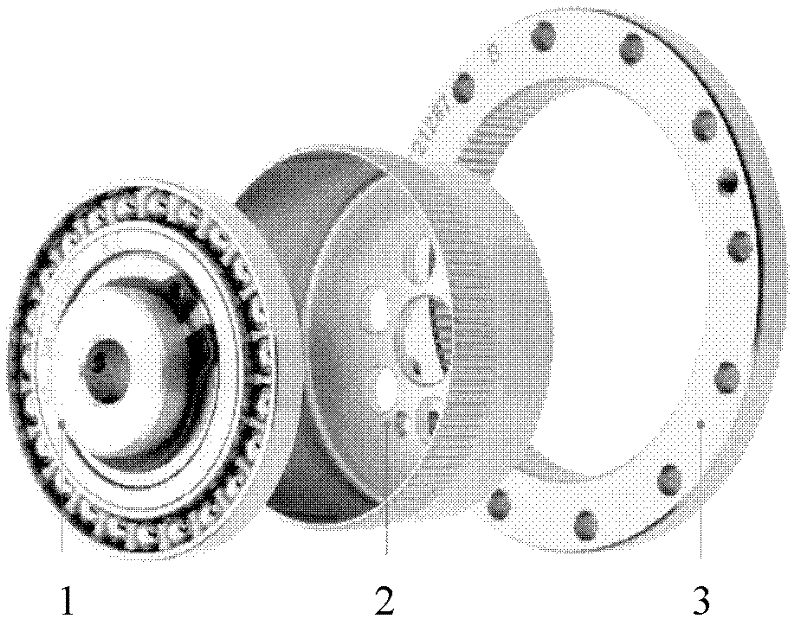

[0020] In this embodiment, the physical model of the harmonic gear for spacecraft is as follows figure 1 As shown, the harmonic gear for spacecraft is mainly composed of three basic components: wave generator 1, flexible spline 2 and rigid spline 3.

[0021] Step 2: According to the physical model of the harmonic gear for spacecraft obtained in step 1, use the reliability simulation technology based on fault physics to determine the underlying fault information of the harmonic gear for spacecraft.

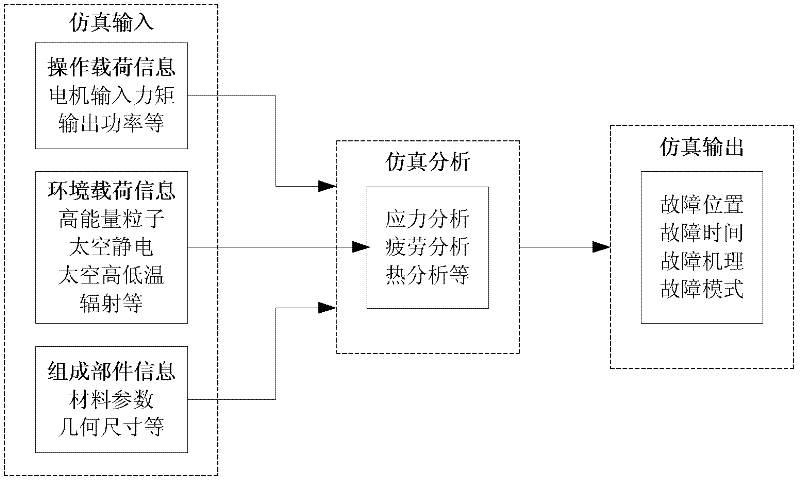

[0022] In this step, if figure 2 As shown, the reliability simulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com